Subsurface data crucial for carbon capture and storage

Ed Hoskin

Ikon Science

Surbiton, UK

A consortium of 20 organizations including research institutions, operators, and regulatory authorities from a total of six countries, organized to create REX-CO2 (ReUsing Existing Wells for CO2 Capture and Storage) to evaluate the potential for mature, near end-of-life wells and fields to be repurposed for carbon capture, utilization, and storage (CCUS) operations.

CO2 can be safely stored in deep geological formations in a process that mimics how oil and gas have been trapped underground for millions of years. Captured CO2 is compressed and injected deep beneath the earth’s surface into a reservoir of porous rock below an impermeable layer of cap rock, which functions as a seal. CO2 is prevented from migrating to the surface by the cap rock as well as other trapping mechanisms—structural, residual, solubility, and mineral trapping—that affect how CO2 behaves in the subsurface. Among available reservoirs for carbon storage, deep saline formations and depleted oil and gas reservoirs offer the largest CO2 storage capacity.

Well decommission in depleted reservoirs has historically been a cost center for oil and gas businesses. The decommissioning procedure is an expensive, complex, multi-step process. In the UK Continental Shelf (UKCS) alone, it is forecast that 1,211 wells across 230 fields will be decommissioned between 2019 and 2028. According to North Sea Transition Authority’s 2021 Decommissioning Cost Estimate report, current projected decommissioning costs for the UK Continental Shelf (UKCS) total $60 billion with efforts underway to reduce that figure to $51 billion by end 2022.

The prospect of reusing these decommissioned wells and fields for CO2 injection provides an opportunity to reduce the time and cost of developing new CCUS infrastructure required by energy-mix diversification efforts. It also presents operators with the possibility of turning decommissioned wells into a profit center by selling CO2 storage capacity to others.

UKCS CO2 storage

As part of the REX-CO2 consortium, Ikon Science collaborated with the British Geological Survey (BGS) in the study phases that evaluated potential for well reuse on the UKCS in two case study areas: the saline aquifer of Bunter Closure 36 in Southern North Sea (SNS) basin and the Hamilton depleted gas field in East Irish Sea basin.

Bunter Closure 36 is a large dome-like structure which was targeted by an exploration well in the 1960s but found to be dry or water-wet. In the 1980s, an exploration well was again drilled through Bunter Closure 36 but this time it targeted a reservoir in the much deeper Carboniferous-Aged Coal Measures. This latter well led to the discovery of Schooner Gas field, and over the decades that followed numerous production wells were drilled through Bunter Closure 36 to produce gas from this deeper target. As a result, a high number of wells which penetrated through Bunter Closure 36 are due for decommissioning in the coming years. These wells were the focus of the project’s well-reuse investigation.

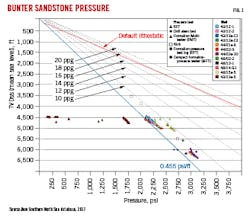

For the study, Ikon used the RokDoc program to analyze a selection of regional wells and those drilled through Bunter Closure 36 to accurately evaluate the subsurface and verify suitability of those wells for both reuse and CO2 injection and storage. As wells in the immediate vicinity of the Bunter Closure 36 case study lacked comprehensive pressure data measurements such as repeat formation tester (RFT) and modular formation dynamics tester (MDT) data due to targeting of deeper Carboniferous-aged reservoirs, Ikon’s SNS well database was used to examine regional wells within the same reservoir and fault block. Fig. 1 shows pressure data from wells in the region around Bunter Closure 36 in the Silver Pit basin area of the SNS.

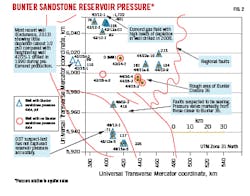

This regional study enabled the team to determine that depletion effects from producing fields, such as Esmond Gas field, were minimal and that present-day pressure is likely nearly hydrostatic, or potentially overpressured to around 200 psi (Fig. 2). Overpressure data shown in Fig. 1 are displayed on a map view with surrounding faults shown in red. Data show that the reservoir is connected and demonstrates good porosity and permeability over a long distance.

Results of initial investigations on reservoir pressure and seal fracture strength—two key parameters that indicate the geological suitability of the field for CO2 injection—confirm the presence of sufficient vertical effective stress within the reservoir for safe CO2 containment.

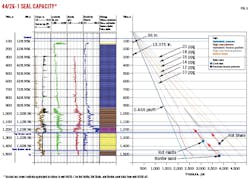

The pressure-depth plot in Fig. 3 from the initial 44/26-1 exploration well drilled in Bunter Closure 36 estimates vertical effective stress and fracture pressure of the reservoir. Predicted fracture pressures are compared with formation limit test (LT) and fracture lclosure pressure (FCP) derived from minifrac tests from the 42/26-d3 well that tested the Rotliegendes (Rot) Halite (LT) and Rot Shale (minifrac), both seals, and the Bunter Sandstone reservoir (minifrac). LT and fracture closure pressure (FCP) data are shown at their measured depths in well 42/26-d3. The dashed arrows point to shallower depths of the respective formations in well 44/26-1.

The Rot Shale and Bunter sandstone FCP measurements (extrapolated up to 44/26-1 formation depths) are at higher fracture pressures than predicted, indicating that the predictions are conservative. Salt LT is lower than estimated by the log, but the nature of the test is to measure below fracture pressure and so the widely applied fracture pressure assumption in salt (fracture pressure = vertical stress) is still valid.

The depth of Bunter Sandstone reservoir traps, including Bunter Closure 36, is greater than 1,000 m. A depth of 1,000 m or greater than 1,000 m results in hydrostatic pressure exceeding 100 bars (1,450 psi), ensuring that injected CO2 will be in its supercritical state at reservoir conditions.1 Injecting supercritical CO2 stores greater volume within the structure compared with CO2 in other states.

In addition to the critical geological subsurface factors noted above, the type of casing and cement in the wells also strongly impacts reuse potential. Corrosion-susceptible steel grades and certain types of cement may reduce a well’s potential to be repurposed for CO2 storage. Additionally, the number of casing strings run through a formation—in this case, the Bunter Sandstone—may require operators to perform extensive downhole operations such as side-tracking, cutting and removing existing casing strings, milling casing and cement, and perforating with large charges to access the reservoir. Such activities could render a well economically impractical for reuse. Older wells at Bunter Closure 36, however, typically have fewer casing strings through the Bunter Sandstone interval which may make them more economically viable to repurpose.

Once wells have reuse potential, another factor to consider is the specific reuse that will be implemented. Wells may be used for three distinct purposes during a CO2 storage operation: water extraction during CO2 injection (for pressure management), monitoring of CO2 plume, or CO2 injection. Careful analysis of several factors determines the most appropriate reuse application. For example, if the well penetrates the reservoir close to the spill point it may prove to be unsuitable for CO2 injection because of the risk of plume migrating beneath the spill point. In this instance, reusing the well for CO2 monitoring may be preferable. Also, the siting of wells where CO2 is injected can impact migration of CO2 through the reservoir. A short migration route near the crest will limit opportunities for residual and solubility trapping. Maintaining a delicate balance between crest and spill point is crucial. Ideally, the well will be midpoint between spill point and crest to allow CO2 to migrate towards the crest under buoyancy.

References

- Chadwick, R.A., Arts, R., Bernstone, C., May, F., Thibeau, S., and Zweigel, P., “Best Practise for the Storage of CO2 in Saline Aquifers,” British Geological Society, Keyworth, Nottingham, Occasional Publication 14, 2008.

Acknowledgement

The presented work was performed in the ReUsing Existing Wells for CO2 Capture and Storage (REX-CO2) project, which is funded through the Accelerating CCS Technologies (ACT) program, Horizon2020 Project No. 299681. Financial contributions are gratefully acknowledged from the French Environmental and Energy Management Agency (ADEME); Netherland’s Ministry of Economic Affairs and Climate Policy; Norway’s Gassnova SF and Research Council of Norway (RCN); the Romanian Unitatea Executiva Pentru Finantarea Invatamantului (UEFISCDI); UK’s Department for Business, Energy and Industrial Strategy (BEIS), National Environment Research Council (NERC), and Engineering and Physical Sciences Research Council (EPSRC); and the US Department of Energy (DOE).

The author

Ed Hoskin ([email protected]) is a technical manager at Ikon Science. He holds a Master’s of earth sciences degree (2003) from University of Southampton.