Added-water heavy crude transport method improves efficiency

Jiaqiang Jing

Jiatong Tan

Min Huang

Jie Sun

Southwest Petroleum University

Chengdu, China

Added-water transportation moves heavy crude in dispersed form without adding surfactant. Heavy oil-water pipe flow is simple and cheap. The water used can be produced oilfield water, taking advantage of its residual heat to conserve energy. This technology is used in Xinjiang oilfield, China. Researchers used a flow loop to study the critical water fraction and temperature, establishing a scientific reference for pipeline design and operation.

Heavy oil and extra-heavy oil reservoirs are found worldwide, including in Venezuela, Alberta, and California.1 Pipelines are the most economic means of transporting heavy oil.2

Heavy crude's high viscosity creates technical and economic problems in shipping. High-temperature heating, for example, aggravates pipe erosion and adds costs. Dilution only works in places with continuous supplies of light oil or condensate. Surfactant for emulsification significantly increases cost.

This article studies the critical temperature and water fraction for safe transportation of two types of Xinjiang heavy oil, K96 and K98. The flow loop tests pump performance under different water fractions to find the water-fraction lower limit for transporting heavy oil early in a well's life and the temperature lower limit for transporting crude late in its production curve.

Theory

Phase inversion is the point at which two immiscible liquids transition from being dispersed to being continuous and vice versa. Phase inversion is quantified as the volume fraction of the dispersed phase at the inversion point.3 The point is marked by the mixture's viscosity peak.4

For the oil-water pipe flow, featuring a continuous phase transition from oil to water, the pressure gradient is a peak following an abrupt decrease. Increasing the water content of oil-in-water emulsions would have little effect on reducing the pressure gradient. The water content for oil-water pipeline transportation therefore must be greater than the phase inversion point to reduce the pressure gradient.

Phase inversion criteria

The phase volume ratio is equal to the square root of the ratio of the phase inversion point's viscosities. Temperature, interfacial tension, and density have no correlation with the system studied. A logarithmic relationship exists between oil viscosity and the input water fraction for the phase inversion point.4 Phase-inversion empirical models only include the viscosity factor.4 Most investigations, however, tested with light mineral oil, few concentrating on the heavy-oil phase inversion criterion.5

Materials

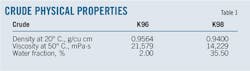

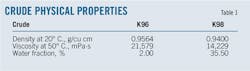

Oil samples came from the gathering pipe in Xinjiang oilfield. A Rheolab QC rotational rheometer equipped with a CC27 concentric cylinder tested rheological properties. Table 1 shows the crudes' physical properties. Fig. 1 shows viscosity behavior. According to the Chinese heavy oil classification standard, K96 and K98 are heavy viscous oil. The water used in the experiments was tap water.

Testing

The critical water fraction experiments took place in the flow loop in State Key Laboratory, Southwest Petroleum University, China. The flow loop consisted of two 6-m test sections made out of 25-mm diameter stainless steel pipe. The whole assembly was 45 m long, immersed in a thermostatic water bath (Fig. 2).

Experiments required a total oil-water volume of 30 l. The oil and water entered the stirring tank in the desired proportion, were heated to the experimental temperature, and stirred for 10 min to achieve a well-mixed sample.

Analyzing the dispersing and clinging properties of the hot oil used a small-scale plant consisting of a funnel, vertical pipe, horizontal pipe, and water bath. The water bath's temperature rose from 50 to 70° C., with the experiment conducted at each 5° C. increment

The first 5-g oil sample travelled through the funnel to the horizontal pipe where it was kept at the desired temperature for 15 min. One liter of water taken from the bath and poured into the funnel used its gravitational potential energy to push the heavy oil sample. The structure of the oil-water flow in the horizontal pipe was video recorded.

Critical water fraction

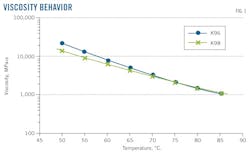

Experimental results show that at 85° C. the K96 crude oil with water less than 55% could not efficiently be pumped and transported (Table 2). Viscometer testing calculated the oil-water mixture's pipe-flow pressure gradients. The viscosity of K98 crude oil with a water fraction less than 50% was also tested with a viscometer at 80° C. The pressure gradients of K96 crude oil with a water fraction greater than 60% and K96 crude oil with more than 50% water were tested with the flow loop.

Fig. 3 shows the relationship between water fraction and pressure gradient. According to the peak points in Fig. 3, the critical water fraction for pipeline transportation is 60% for K96 crude oil and 50% for K98 crude oil.

This critical water fraction is different from the phase inversion point. The phase inversion point is defined as the water fraction where the dispersed phase inverts to become the continuous phase. The velocity in this experiment is comparatively low and the oil viscosity is high. The Reynolds number is less than 2,000 and the oil and water is separately transported in laminar flow and unable to disperse. The water flows in the bottom of the pipe and the oil on top. The oil and water flow in stratified form.

Fig. 4 shows temperature's effect on critical water fraction, which was limited to low-temperature conditions. For 60° and 65° C., for example, pressure gradients decrease when the water fraction increases from 70% to 75%. With increasing temperature, the effect of water fraction on pressure gradient gradually decreases. At high temperatures, for example 80° and 85° C., pressure gradients don't change suddenly even within a water-fraction range of 60% to 80%.

K98 crude's viscosity is relatively low, with the peak point presenting early. At low temperatures (60-70° C.), the peak point presents between 55% and 60%. At high temperatures (75-85° C.), the peak point presents between 50% and 55%; the higher the temperature, the lower the critical water fraction. At a constant flow rate, increasing the water fraction would help decrease transportation temperature and pressure gradient.

Critical temperature

A well typically has less production and higher water content later in life. Recycling produced water would use its thermal energy and reduce the possibility of pipe blocking. Analyzing entrained oil volume allows determination of the critical transportation temperature.

At 50° C. K96 crude could hardly flow into the horizontal pipe, with oil slugs forming. Crude was entrained for a short distance and then clung to the pipe wall due to the low temperature.

At 55° C. the crude oil slug clung to the pipe wall. A large amount of separated water presented in the pipe. Air slugs presented with increasing water flow rate. Bubble flow was observed in the elbow.

The oil layer stayed at the top of the pipe during experiments. Separated oil occasionally entrained with the water flow and oil-in-water dispersion flow presented.

At 60° C. the oil slug presented only near the inlet and became thinner. Near the outlet, the dispersed oil droplet become continuous phase and stratified flow replaced slug flow.

Hot water entrained more oil than cooler water. A big oil droplet initially was entrained by the hot water. Oil-in-water dispersed flow presented. Three-layer flow presented as the experiment continued: oil flow on the top, oil-in-water dispersion in the middle, and water on the bottom. The oil layer is smaller than then the other two regions.

At 70° C. stratified flow emerged. At low velocity the oil layer and water layer flowed separately and smoothly. With increasing flow rate the oil-water interface began to undulate, its wavelength becoming shorter. More crude oil flowed to the outlet than in other conditions.

Fig. 5 shows the percentage of oil captured in the beaker. A higher percentage value shows higher entraining. The oil entrained by 60° C. water is double that of 55° C. water. And 65° C. water entrained almost twice the oil 60° C. water. The water should be at least 60° C. for safe transportation and 65° C. for high-efficiency transportation.

Phase-inversion prediction

Theoretical values6 show good agreement with the process observed experimentally for oil less viscous than 10 millipascal seconds (mPa·s). The Decarre and Faber7 model performs better for highly viscous oil than other models, but its deviation is not satisfactory.

The material used in these experiments might cause the deviation. All previous models tested with white oil or light hydrocarbon, which contains little emulsifier. The input water fraction for phase inversion decreases with oil viscosity.

Viscous heavy oil, meanwhile, contains large amounts of resin and asphaltenes, both of which are natural emulsifiers. The emulsifiers could stabilize the dispersion by preventing rupture of the water droplets and strengthening interfacial films.8 Heavy oil, therefore, is expected to inverse at a higher input water fraction then mineral oil with a similar viscosity.

Existing phase inversion models do not account for natural emulsifying agents and thus are not applicable to heavy oil. Further investigations are needed on the effects of resin, asphaltene, and solid particles.

Field experiments

Researchers added produced water without additives to 14 heavy-oil gathering pipelines in Xinjiang field, removing their steam heating systems. Fig. 6a gives basic production data of produced fluid and added water fractions. Fig. 6b shows the change in wellhead temperature and backpressure.

Adding produced water only slightly increased wellhead backpressure, which remained well within gathering pipe requirements. The practice also effectively reduced blocking in pipelines attached to low-production wells. Using produced water could save an average of 1.8 tons of steam/well/day.

References

1. Warwick, P.D. and Hackly, P.C., "Unconventional Energy Resources: 2013 Review," Natural Resources Research, Vol. 23, No. 1, March 2014, pp. 19-98.

2. Martinez-Palou, R., de Lourdes Mosqueira, M., Zapata-Rendon, B., Mar-Juarez, E., Bernal-Huicochea, C., de la Cruz Clavel-Lopez, J., and Aburto, J., "Transportation of heavy and extra-heavy crude oil by pipeline: A review," Journal of Petroleum Science and Engineering, Vol. 75, No. 3-4, January 2011, pp. 274-282.

3. Angeli, P., and Hewitt, G., "Pressure gradient in horizontal liquid-liquid flows. International Journal of Multiphase Flow, Vol. 24, No. 7, November 1999, pp. 1183-1203.

4. Arirachakaran, S., Oglesby, K., Malinowsky, M., Shoham, O., and Brill, J., "An analysis of oil/water flow phenomena in horizontal pipes," SPE Production Operations Symposium, Oklahoma City, Mar. 13-14, 1989.

5. Wang, W. and Gong, J., "Experiment research of phase inversion in mineral oil-water two-phase flow in horizontal pipe," Journal of Energy Resources Technology, Vol. 131, No. 4, December 2009.

6. Wang, W. and Gong, J., "Improved phase inversion model during oil-water two-phase fluid flow in pipeline," Acta Petrolei Sinica, Vol. 29, 2008, pp. 139-142.

7. Decarre, S. and Fabre, J., "Phase inversion behavior for liquid-liquid dispersions," Revue de l Institut Francais du Petrole, Vol. 52, No. 4, July-August 1997, pp. 415-424.

8. Wong, S, Lim, J., and Dol, S., "Crude oil emulsion: A review on formation, classification and stability of water-in-oil emulsions." Journal of Petroleum Science and Engineering, Vol. 135, No. 11, November 2015, pp. 498-504.

The authors

Jiaqiang Jing ([email protected]) is a professor at Southwest Petroleum University and a researcher at Oil & Gas Fire Protection Key Laboratory of Sichuan Province, both in Chengdu, China. He holds BS (1987), MS (1990), and Ph.D (1999, oil and gas storage and transportation) degrees from Southwest Petroleum University. He is a member of Chinese Petroleum Society and Society of Petroleum Engineers (SPE).

Jiatong Tan ([email protected]) is Ph.D. candidate at Southwest Petroleum University, Chengdu. She holds a BS (2011) in oil and gas storage and transportation from Southwest Petroleum University. She is a member of SPE.

Min Huang ([email protected]) is researcher of Chengdu Branch of China National Petroleum & Natural Gas Mass Flowrate Calibration Station, Chengdu. She holds a BS (2007) and MS (2010) in oil and gas storage and transportation from Southwest Petroleum University.

Jie Sun ([email protected]) is Ph.D. candidate in oil and gas storage and transportation at Southwest Petroleum University, Chengdu, China. He holds a BS from Southwest Petroleum University.