Simulation studies of steam recovery processes in offshore China heavy oil reservoirs

Wankun Xu

Fengyi Zhang

Dawei Wang

Tingting Wu

CNOOC Ltd. Tianjin Bohai Oilfield Institute

Tianjin, China

Xiaoha Dong

China University of Petroleum

Beijing

Jinze Xu

Zhangxin Chen

University of Calgary

Calgary

A combination of cyclic steam stimulation (CSS), steam drive (SD), and steam-assisted gravity drainage (SAGD) can improve thermal recovery in heavy oil reservoirs in Bohai offshore oil field in the central Bohai Gulf.

Bohai's heavy oil reservoirs present severe heterogeneity and complex water zones, properties that complicate development. The reservoirs, usually deposited at more than 1,000 m, are classified into three types:

• Thin water-zone.

• Thicker water-zone.

• Lean zone.

Researchers studied thermal recovery processes for each type of reservoir to determine which process worked best given reservoir thickness, oil viscosity, reservoir permeability, vertical and horizontal permeability ratio, and water-oil thickness ratio.

Reservoir simulation studies and field experiences demonstrated CSS-SD works best in heavy-oil reservoirs with thin-bottom water. SAGD was most appropriate in thick bottom-water reservoirs with horizontal wells. CSS-SD yielded a higher cumulative oil-steam ratio (COSR) and recovery factor in the lean-zone reservoirs.

Table 1 provides the classification of Bohai offshore field's heavy oil reservoirs: NanBao 35-2 (NB 35-2), QinHuangDao 35-2 (QHD), LvDa-1 (LD-1), LvDa-2, LvDa-3 and LvDa-4. The representative wells are B04M in NB 35-2 reservoir, LD-2-4N in LD-2 reservoir, and LD-4-1 in LD-4 reservoir.

Other researchers had found CSS-SD and SD outperformed SAGD for developing thin water-zone heavy oil reservoirs in onshore fields.1-5 The authors of this article focused on CSS-SD and SD for developing an offshore thin water-zone heavy oil reservoir, comparing and analyzing the recovery performances of all three processes on the different types of reservoirs.

The existence of lean zones effects the formation and expansion of a steam chamber, limiting the usefulness of SAGD.6 Bohai field's lean zone led this article's authors to study CSS and SD for that area.

Numerical simulation models

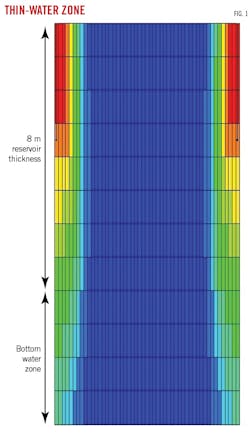

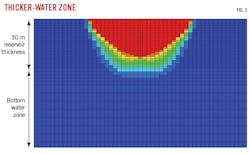

Figs. 1-3 show the three reservoir models and numerical simulation models developed for each. The thin water-zone heavy oil reservoir model has a 5 × 51 × 21 grid system (400 m × 102 m × 48 m). The thicker water-zone heavy oil reservoir model has a 5 × 51 × 49 grid system (400 m × 102 m × 330 m). The lean-zone heavy oil reservoir model has a 5 × 51 × 20 grid system (400 m × 102 m × 20 m).

Refined grids produced similar simulation results. A simulator automatically selected the time steps to ensure stability of the numerical schemes (finite volumes in space and adaptive time integration). Both the steam injection well and the oil well have a 300-m horizontal section.

Table 2 shows the parameters used in simulation runs. Oil viscosity is highest in the thicker water-zone heavy oil reservoir. The models figured the same production constraints into the CSS and SD processes. The steam quality is 80%. The steam injection rate is 240 tonne/d.

For SAGD, the temperature difference is controlled within 15 °C. The operation pressure is 3 MPa. The three models simulated a 20-year production life based on the anticipated life of the offshore platform.

Switching CSS to SD in the simulations after seven cycles allowed strategic consideration of the CSS-SD combination.

Results and Discussions

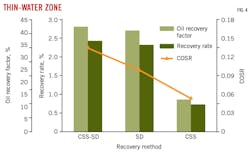

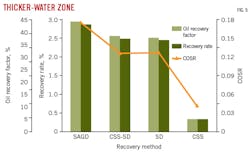

Figs. 4-6 show the recovery performance results from a series of simulations on the different heavy oil reservoirs. Models forecast effective thermal recovery methods by recovery rate, recovery factor, and COSR for each reservoir type.

Fig. 4 shows the CSS-SD process yielded the highest recovery results for the thin-water zone.

The COSR of CSS-SD process increased by 11% compared with CSS performance.

Fig. 5 shows results for the thicker water-zone where the SAGD process had the best recovery factor, recovery rate, and COSR.

The oil recovery factor of CSS was only 5% due to higher formation thickness, existence of a bottom aquifer, and CSS's limited thermal sweep efficiency. In addition, its recovery rate and COSR were the lowest.

Fig. 6 shows the simulated recovery rate, recovery factor, and COSR results of the three processes of the lean-zone heavy oil reservoir. The CSS-SD recovery process model shows the highest recovery factor, recovery rate, and COSR for the lean zone.

The CSS model shows the lowest oil recovery rate and COSR, resulting from its limited thermal sweep efficiency.

For the recommended CSS-SD combination, CSS established a heat connection between the steam injection well and the production well before the SD process starts.

Sensitivity studies

Sensitivity studies for the three processes and their corresponding reservoir models examined the effects of reservoir parameters on performance. For offshore oil reservoirs, the recovery rate is a more important indicator than the oil recovery factor.

The recovery rate and COSR measure recovery performance. Researchers numerically studied the thermal recovery processes' adaptability in Bohai field's reservoir types.

Table 3 shows the results and final recommendations. For the heavy oil reservoir with a thin water zone, a CSS-SD process is suitable. The studied formation is relatively thin (8-15 m), permeability is greater than 1,000 × 10-3μm2, Kv/Kh ratio is higher than 0.3, and the water zone is low with a water-oil net ratio of < 1.

SAGD is suitable to a reservoir more than 25 m thick, with a thicker water zone, horizontal permeability greater than 2,000 × 10-3μm2, and a Kv/Kh ratio higher than 0.3.

For a heavy oil reservoir with lean water zones, CSS and SD processes are suitable. Other reservoir parameters applicable to this choice are thickness greater than 15 m, oil viscosity less than 30,000 cp at 50° C., horizontal permeability greater than 1,000 × 10-3μm2, and Kv/Kh ratio higher than 0.3.

Acknowledgments

The authors acknowledge the financial support of National Science and Technology Major Project (20162X05058-001-008), CNOOC Ltd. Tianjin Bohai Oilfield Institute, the NSERC/AIEES/Foundation CMG Chair, and the AITF (iCORE) Chair.

References

1. Butler, R., "Thermal Recovery of Oil and Bitumen," Prentice Hall, Englewood Cliffs, NJ, 1991.

2. Farouq Ali, S., Jones, J., and Meldau, R., "Practical Heavy Oil Recovery," University of Alberta, Edmonton, 1979.

3. Kendall, G., "Importance of Reservoir Description in Evaluating In-situ Recovery Methods for Cold Lake Heavy Oil," Petroleum Society of Canada Journal of Canadian Petroleum Technology, Vol. 16, No. 1, January 1997, pp. 41-47.

4. Kasraie, M., and Farouq Ali, S., "Heavy Oil Recovery in the Presence of Bottom Water," Petroleum Society of Canada Annual Technical Meeting, Calgary, June 10-13, 1984.

5. Delamaide, E., and Moreno, W., "Enhanced Oil Recovery of Heavy Oil in Reservoirs with Bottom Aquifer," Society of Petroleum Engineers (SPE) Western Regional Meeting, Garden Grove, Calif., Apr. 27-30, 2015.

6. Samuelsen, E., Langlais, V., Svanes, T., Dalen, V., and Tyler, K. "Evaluation of Flooding Strategies for a North Sea Reservoir Using Stochastic Techniques to Model Heterogeneities," SPE-Department of Energy Ninth Symposium on Improved Oil Recovery, Tulsa, Apr. 17-20, 2013.

The authors

Wankun Xu ([email protected]) is a reservoir engineer at Binhai New Area of Tianjin, Bohai oil field since July 2010. He researched multiple-thermal fluid mechanisms and offshore thermal recovery programs, such as CSS and SAGD, during 2010-16. He obtained his BS and MS in oil and gas field development engineering, from China University of Petroleum, East China.

Zhang Fengyi ([email protected]) is a CNOOC Ltd. Tianjin Bohai Oilfield Institute reservoir engineer with more than 10 years' experience in the oil and gas industry. He holds a BS (2004) and MS (2007) in reservoir engineering from China University of Petroleum. His research interests are development and production of offshore heavy oil.

Dawei Wang ([email protected]) is a reservoir engineer at Binhai New Area of Tianjin, Bohai oil field since July 2012. He researched the development programs of offshore heavy oil field from 2012-17. He holds a BS (2004) in chemical engineering and an MS (2009) and PhD (2012) in oil and gas field development engineering from Southwest Petroleum University, China.

Tingting Wu ([email protected]) is a reservoir engineer at Binhai New Area of Tianjin, Bohai oil field since July 2011. She researched numerical simulation technology in thermal recovery for offshore oilfields and thermal recovery technologies for heavy oil reservoirs, such as thin interbed common heavy oil reservoir and massive block extra-heavy oil reservoir during 2011-16. She obtained her BS and MS in oil and gas field development engineering from Northeast Petroleum University.

Xiaohu Dong ([email protected]) is an assistant professor at the Department of Petroleum Engineering, China University of Petroleum, Beijing, since 2016. Previously, he worked as a postdoctoral fellow at the University of Calgary, 2014-16. He holds a BS (2009) and PhD (2016) in petroleum engineering from the China University of Petroleum, Beijing. Dong's research includes phase behavior modeling in unconventional resources and thermal and non-thermal recovery methods for heavy oil.

Jinze Xu ([email protected]) is a PhD student at the University of Calgary Department of Chemical and Petroleum Engineering. He obtained an MS (2015) in petroleum engineering from the University of Calgary and a BS (2011) in petroleum engineering from China University of Geosciences, Beijing. He researches heavy oil, oil sands, and shale gas.

Zhangxin Chen ([email protected]) is a University of Calgary petroleum engineering professor. He currently holds the Natural Science and Engineering Research Council Chair, and Computer Modelling Group Chair and is the Industrial Research Chair in Reservoir Simulation, and the Alberta Innovates Technology Future (iCORE) Industrial Chair in Reservoir Modeling. He is director of the University of Calgary's iCentre for Simulation & Visualization. He earned a PhD (1991) from Purdue University, West Lafayette, Ind.,an MS (1985) from Xi'an Jiaotong University, China, and a BS (1983) from Jiangxi University, China. He was a professor and reservoir engineer at Xi'an Jiaotong University, Peking University, University of Minnesota, Texas A&M University, and Southern Methodist University. His research interests are reservoir engineering and numerical reservoir simulation for conventional and unconventional reservoirs.