KOC pilots test integrated digital oil field approaches

Adel Al-Abbasi

Ahmad Al-Jasmi

Hatem Nasr

Kuwait Oil Co.

Kuwait City

Kuwait Oil Co. launched simultaneously three major pilot projects with a fourth project in the planning phase, to demonstrate the benefits of the integrated digital oil field.

Two projects are in two different oil fields, and one project is in a gas field. The number of wells in each project range from 30 to 55.

The projects led by various major oil service companies are coming on line with some already streaming real-time well data. The projects are proceeding to install complete instrumentation on the wells (surface and downhole), collaboration rooms, and modeling and optimization software and servers, as well as to implement intelligent work flows.

KOC expects all three projects to be completed by midyear.

The pilot projects are the result of KOC taking the time to carefully analyze and observe what the industry has done in the past few years. As a result, it has taken this approach for conceptualize Kuwait's integrated digital oil field (KwIDF).

This article will discuss KOC's plan for the next generation integrated digital oil field.

Integrated digital oil field

Oil and gas companies face major challenges for meeting increased energy demands around the world. Existing fields are depleting rapidly and finding large new reserves has become increasingly difficult. As a result, companies have put forward various strategies to find ways to increase recovery from existing reservoirs.

Currently, reservoir recovery in the industry is low, in most cases far less than 50%.

One way companies are trying to improve recoveries is through technology initiatives such as integrated digital oil field approaches. Some companies also refer to these approaches as smart fields, I-fields, or eFields.

These initiatives involve installing integrated systems that allow continuous monitoring of well performance and production, perform optimization, and control wells and fields.

Companies have launched many projects during the last few years. But while many have been successful, there is great uncertainty on how to go forward.

Lessons learned

Many major oil and gas companies and large national oil companies have implemented several projects on a digital oil field and many are ongoing.

Several projects have demonstrated promising results. Many studies done by several organizations and oil companies indicate many benefits for these concepts. Also studies and pilot projects have demonstrated good return on investment for these projects.

The benefits are not limited to increasing production rates and reducing production deferment but also include improved reservoir recovery factors.

The industry, however, faces some challenges in these implementations. KOC reviewed the industry's experience and made some important observations:

• Many initiatives and projects had limited trials that were typically on a few wells, resulting in uncertain and in many cases incomplete assessments.

• Many systems emphasized simply real-time data capture, mostly for monitoring of operations and did not address the complete integration that involves remote control of oil field operations and also addresses the reservoir.

• Many projects simply dealt with a short term and did not address the long-term.

• Many projects lacked transformative change management strategy and company culture change for long-term adoption of the technology.

• Many projects did not try alternative technologies or perform tradeoff among various industry offerings.

KwIDF projects

In each of the KOC's three pilots, oil service companies have been teamed with several technology suppliers to provide various subsystems.

KOC's intent in bringing in multiple oil service companies was to promote innovation, spirited competition, and collaboration among the various projects. KOC also set up internal project management whereby the KOC project managers and various KOC asset teams worked together on all three projects. The KOC project managers share information among the various projects, best practices, technical issues, and solutions.

KOC believes that no single service company has the best solution for every aspect of technology, but each service company brings skills to individual problems. So that when the time comes for a large commercial rollout of the KwIDF projects across various KOC assets, these project might include integrated components from various companies.

Each KwIDF project involves the deployment of complete end-to-end systems from the reservoir to sales (Fig. 1). These systems involve a wide range of new and existing technologies.

KOC decided not to take the traditional approach and implement only proven technologies, but also deploy new generation technologies that may not be fully proven in the oil and gas industry. It encouraged the oil service companies and KOC engineers to consider cutting edge technologies for various applications.

Surface systems

Each project involved the installation of a complete set of instrumentation on the wellheads. This includes the latest generation of pressure sensors, temperature sensors, flow measurement meters, water cut meters, choke valves and actuators, control panels, H2S sensors, corrosion sensors, chemical injection pumps, chemical tank level monitoring, and more.

Some projects equipped their wells with real-time video surveillance. Many wells included permanent multiphase metering as well as portable mobile well test units for frequent well tests.

The projects in the oil fields included a variety of wells such as free flowing wells, gas lifted wells, electrical submersible pumped wells, and water injection wells.

The projects involved upgrading the instruments on the artificially lifted wells. The ESP wells will have variable-speed drives; some will have multiphase meters and ESP optimization equipment at the wellsite that contain well models.

Subsurface systems

The projects include the installation of permanent downhole gauges and fiber optic distributed temperature sensors on many wells. A few selected wells (producers and injectors) include smart wells and inflow control valves for intelligent completion.

In some projects, real-time seismic monitoring system is being implemented to provide continuous monitoring of reservoir conditions, and water and hydrocarbon movement.

The deployment of permanent real-time seismic monitoring is a first in the industry and is an example of how KOC is deploying a technology that has shown promise for many years.

Wireless SCADA

All the projects involve the deployment of complete wireless supervisory control and data acquisition (SCADA) systems in which remote terminal units at the well site continuously collect real-time data from all well surface and subsurface instruments and connect via a new generation Wimax wireless network to SCADA software in KOC's offices.

KOC laid out a Wimax wireless communication infrastructure across all its assets to provide high bandwidth, high-speed link to all wells and facilities.

An information technology infrastructure provides secure data access and control of well systems. The IT infrastructure facilitates data streaming and control while ensuring proper separation of various monitoring and control functions.

Modeling, optimization

Each project involves comprehensive well and reservoir modeling. Well model's recalibration is based on the latest well test data.

The process involves continually refining and updating the models based on real-time data. Because models are only an estimation of the well and reservoir conditions, it is important to address the model's uncertainty in order to make better performance predictions and simulations.

The optimization systems use conventional analytical methods. Because conventional methods, however, may not be sufficient in many cases, some projects are exploring the latest technology including artificial intelligence methods, neural networks, and fuzzy logic.

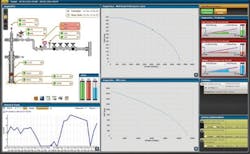

The optimization system (Fig. 2) not only makes recommendations on how to control the wells (such as choke valve setting or varying ESP frequency, or gas lift valve setting) but also includes predictive and causal analysis. Such predictive analysis will allow operators to optimize (in the short term) not only well production, but also the reservoir and the asset (in the long term).

Several implemented work flows address integrated asset planning and integrate data from the wells to the pipeline network and to the facilities systems.

Collaboration, field control room

Each project will have a field control room, to monitor real-time data, observe well alarms, identify operational requirements and control the wells.

In KOC's headquarters, large collaboration rooms will allow the execution of various work flows, monitoring of key performance indicators, updating of well and reservoir models, analysis of system optimization results, and making of midterm and long-term decisions.

The collaboration rooms (Fig. 3) have a new design and building infrastructure fit for these applications and include display and screen technology.

These projects also address special designs of furniture, desks, and other aesthetics for providing a comfortable and productive working environment.

Data visualization

In the control and collaboration rooms, portal software systems (Fig. 4) will link various data components and existing KOC databases and repositories. This includes not only real-time well data but also existing reservoir data, geological data, seismic data, and well log data.

The portal software has a user interface and provides visualization.

Intelligent work flows

Each system is a collection of various work flows for monitoring real-time well events, analyzing the data, updating well and reservoir models, running optimization algorithms, predicting well and reservoir conditions, and making well control decisions (Fig. 5).

The work flows are a decision support system for short-term well planning, intervention, and operations. They also provide key tools for asset development such as the running of various simulation and what-if scenarios for making long-term plans.

Change management

KOC realized from the early phase of planning for these projects that no matter how good the technology, the only way these projects can succeed is if the organization embraces and uses the technology.

The entire KOC organization has to be aware of project goals (Fig. 6), technology benefits, and its uses. Awareness must be across the entire organization structure from technicians to engineers to higher level management.

KOC adopted an awareness and communication plan to ensure that everyone knows that these projects are being implemented. KOC's research and technology (surface) team worked in close collaboration with the various service companies, the end users, asset development, and groups across the entire organization.

Each project had task force team that involved various members from different organization.

KOC is staffing the collaboration and control rooms by full-time engineers with various specialties. It has defined new job functions and a manning plan across the organization to attract the best engineers to work in the collaboration centers.

The authorsMore Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com