Offshore P&A operations overcome pandemic logistics restrictions

Offshore plug and abandonment (P&A) operations require marine and air services to transport specialized equipment and personnel to the rig. In 2020, worldwide COVID-19 travel restrictions hampered many of these operations and pushed operators to revise logistics to perform contractual P&A programs. Crew rotation schedules, embarkation and debarkation points, self-isolation and quarantine guideline, and equipment supply contracts were all revised to accommodate pandemic restrictions.

Petronas Carigali Sdn Bhd performed P&A programs in 2020 which included these revisions. One program decommissioned deepwater subsea wells offshore Mauritania, and another abandoned subsea gas wells offshore Malaysia.

Additionally, a recent paper on P&A operations offshore West Malaysia from UZMA Engineering Sdn. Bhd. describes the first application of a hybrid hydraulic pulling unit (HHPU) for work in this area. While the paper makes no references to operational adjustments to cope with COVID-19 restrictions, the unit’s reduced crew size and faster working time over conventional rigs offers advantages in dealing with pandemic restrictions.

Mauritania P&A personnel management

Petronas implemented an abandonment and decommissioning program on a field about 80 km offshore Mauritania in 730-830 m of water. Nine oil production subsea wells, five water injection subsea wells, hinged-over subsea templates (HOST), manifolds, flexible flowlines, umbilicals, and risers were tied back to a permanently moored floating, production, storage, and offloading unit (FPSO). An additional gas injection well was in an adjacent field about 17 km away in about 280 m of water.

The field reached maturity in 2016 and was ready for P&A and decommissioning due to low oil prices, high operating costs, and limited production. Phase 1 decommissioning was executed in 2017-18 with all 15 deep-water subsea wells suspended with two barriers in place. The FPSO was decommissioned and disconnected. Phase 2 required well P&A which began in December 2019 using a drillship.

Logistics in Mauritania are difficult due to limited flight connections and its location outside normal marine trade routes. Petronas began a risk assessment and mitigation plan on Mar. 1, 2020, based on mounting difficulties moving crews in and out of country. In-country medical services were also becoming strained, requiring an additional safety plan.

The first risk addressed was bringing infection onto the rig. This risk was mitigated by identifying and prohibiting crews from five initially identified high-risk countries. Crews were also not allowed to transit though those countries on the way to the rig. One week before travel, all crews submitted self-declarations of their prior 14-day travel history to high-risk countries to the rig radio operator or medic.

Immediate screening for symptoms during crew changes was performed before heading offshore. Once onboard, rig personnel were trained in recognizing symptoms and increasing hygiene awareness since no PCR or antigen tests were available at the time. Handrails and common areas were frequently sanitized.

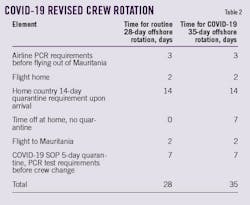

Contractors had rig backup personnel on hand for emergency cases when personnel had to demobilize the rig. Petronas also had contractors extend tours of duty to 35 days from 28 days for more flexibility in logistics in case of cancelled flights. Dakar, Senegal, was identified as an alternative point of embarkation and disembarkation for crew changes.

The operator retrieved three subsea christmas trees, cut tubing in six wells, and abandoned three wells before Mauritania ordered complete border lockdown through force majeure Mar. 17, 2020, giving only 3 days’ notice to Petronas and contractors. Given the strain on medical services in Mauritania, the health, safety, and environmental (HSE) risk was too high, and operations were shut down after performing P&A on the third well.

Before lockdown, the operator evacuated all nonessential personnel, both operator and contractor, out of country to support operations remotely. After lockdown, personnel were evacuated out of Mauritania on the drillship, which sailed to Las Palmas, Spain, to wait on standby. All personnel were safely evacuated out of Las Palmas, though some had to wait for clearance from their home country. Major equipment was kept onboard the drillship for quick startup upon resumption of activity.

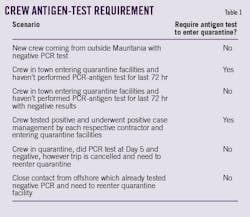

On October 2020, operations resumed with a new COVID-19 standard operating procedure. Among these procedures were requirements for contractors to handle employees’ health and provide replacement crew if required, formalized travel screenings, antigen test and quarantine requirements (Table 1), temperature and symptom monitoring, mandatory face mask requirements, and routine disinfections.

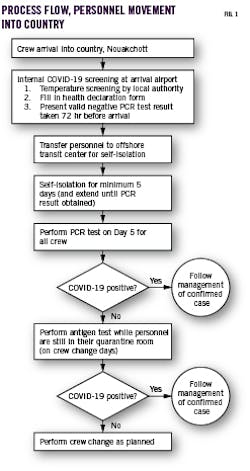

Flowcharts were developed to manage personnel movement into country (Fig. 1), suspected cases with symptoms, and evacuation of suspected or confirmed cases from offshore. A quarantine and COVID-19 real-time PCR testing program were developed following International Association of Oil & Gas Producers (IOGP) Health Committee guidelines on testing in the oil and gas industry. The program was implemented in Mauritania upon personnel’s arrival and before crew change to the rig.

Tour of duty was formally increased to 35 days based on quarantine requirements from date of arrival before onboarding rig and potentially another 14-day quarantine requirement in home country upon return as well as uncertainty regarding expatriate crew replacing onboard crew due to travel restrictions. Table 2 outlines crew rotation revisions. The only difference is in additional time off at home without quarantine, but the additional time off also allows for additional travel time if required. A plan was put in place for alternate crew change locations in case Mauritania’s border closed, using an offshore supply vessel out of Las Palmas with 3-day transit time.

Operations resumed Dec. 31, 2020, following COVID-19 health and logistic procedures. All 15 wells were abandoned and decommissioned by Aug. 13, 2021.

Sarawak subsea campaign

Petronas implemented a permanent P&A campaign for subsea wells in a gas field at Central Luconia Province, about 250 km northwest of Bintulu, Sarawak, in about 300 ft of water. The field consists of two subsea horizontal producers. First gas produced in 2002 but the field was shut in during 2006 due to pipeline buckling and watering out. The field had no further development potential and a subsurface well abandonment plan was created for 2020.

A semisubmersible rig was contracted for P&A operations. The main objective was to establish two barriers for every flowable hydrocarbon system or overpressure-bearing sand by placing laterally extended cement plugs across impermeable formations able to handle the pressure.

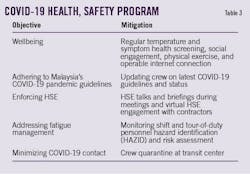

On Mar. 18, 2020, Sabah and Sarawak implemented a movement control order (MCO) to address a series of national quarantine and cordon sanitaire measures encompassing restrictions on movement, assembly, and international travel. The MCO enforced a mandatory 14-day self-quarantine which directly affected travel to the field, delaying the start of the P&A campaign by 2.5 months. During the delay, COVID-19 procedures were established to minimize risk of infection. Crew logistics and mental wellbeing from longer duration rotations were also addressed. Table 3 shows adopted COVID-19 health and safety initiatives.

Like Petronas’s Mauritania experience, flight restrictions hampered crew changes from outside Malaysia. Extensive coordination with the Immigration Department of Malaysia during MCO, advanced manpower planning involving critical personnel, and detailed flight options resulted in rig operations starting a week earlier than the target date. Material fabrication and delivery were also compromised during MCO and were addressed by increasing the options available for supply and using as much local material as possible.

The MCO evolved to a conditional MCO (CMCO) from May 13 to June 9, and then to a recovery MCO (RMCO) from June 10 to Aug. 31. CMCO relaxed MCO regulations and allowed most economic sectors to operate while observing social distancing and contract tracing. Interstate travel was still restricted except for work purposes. RMCO opened interstate travel, religious activities, conventions, and schools to the public (with restrictions).

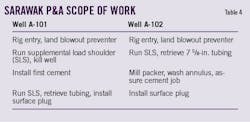

The P&A campaign started in June 2020 under CMCO and was completed by August under RMCO. The wells had limited data and no previous interventions, resulting in little guidance regarding the condition of the wellbores and completions. Both had persistent annulus pressure issues and contained CO2, H2S, and mercury contaminants. Scope of work for the wells is shown in Table 4. The P&A campaign on both wells was successfully completed with no HSE incidents recorded.

Offshore Malaysia hybrid hydraulic workover unit

P&A operations offshore West Malaysia used an HHPU to reduce crew size and decrease working time versus conventional rigs or hydraulic workover units (HWU).

In 2021, conventional drilling rig day rates averaged about $85,000/day. HWUs average 40% to 60% less than that, but typically only can remove tubing and small casing, leaving large conductors to be completed by a rig or larger pulling unit. The dual operations increased manpower and time.

The HHPU was invented in 2019 to pull out existing completion strings and conductor with up to 36 in. OD, using a combination of big-bore casing jack and an HWU system in a single operation without requiring changeover to another unit. Maximum pulling capacity is 340,000 lb and snubbing capacity is 148,000 lb. The unit can pull tubing as small as 2 3/8 in. and as large as a 30-in. conductor with a 6-in. conductor collar. It was built from a standard 340,000-lb HWU, shares the same footprint, and is certified per API 4F requirements for drilling and well servicing structures.

The HHPU can fit a 14 ×14-m deck space with associated equipment and is modular to accommodate small areas such as wellhead or jacket-type platforms. Main components include well control (BOP, Koomey, manifolds), adaptor for BOP to jack base, hydraulic jack, lower, middle, and top work baskets, slips (2 3/8-36 in.), tubular handling, gin pole, power pack, and mud pump (Fig. 2). The HHPU can rig up either on wellhead or skid beam, depending on rig clearances and platform integrity. Rigging up on skid saves time by moving the HHPU over the next well using the hydraulic skidding system. Only the BOP and riser are required to be re-rigged.

HHPU was used in a three-well P&A campaign offshore west Malaysia with a platform area about the same size as the footprint of the HHPU. The existing 3 ½-in. tubing and 9 5/8-in. casing were retrieved by rigging up directly on the wellhead. After removal of casing and tubing from all three wells, skid beams were installed and HHPU re-rigged on beams. The 24-in. conductor, 13 3/8-in. surface casing, and 9 5/8-in. production casing were internally cut and safely retrieved 73 m below water depth by sequentially skidding the HHPU over wells, saving rig-up and rig-down time. The campaign was completed in 38 days with no recorded incidents or accidents.

References

- Sellapan, S., Allapitchai, M.S.M., Johan, A.L., Heboul, E.K.M.M., Liew, W.S.Y., Zaini, A.H.A., Razak, M.H.A., and Yaakub, M.Y., “Challenges and Lessons Learnt Operating During Covid-19 Pandemic in Remote Locations: A Success Story of Mauritania Deepwater Abandonment and Decommissioning Campaign,” SPE-208460-MS, SPE Symposium: Decommissioning and Abandonment, virtual, Nov. 30-Dec. 23, 2021.

- Utta, A.M., Barat, J.A., Maluan, L.B., Omar, M.Z.B., Yahaya, F.B., and Nasron, B.M.B., “Best Practices for Managing Subsea Well Plug and Abandonment Operation in Offshore Malaysia During COVID-19 Pandemic,” SPE-208465-MS, SPE Symposium: Decommissioning and Abandonment, virtual, Nov. 30-Dec. 23, 2021.

- Ahmad, T.K.I.T. and Abdullah, A.H., “Low Cost Plug and Abandonment with Hybrid Hydraulic Pulling Unit,” SPE-208473-MS, SPE Symposium: Decommissioning and Abandonment, virtual, Nov. 30-Dec. 23, 2021.

About the Author

Alex Procyk

Upstream Editor

Alex Procyk is Upstream Editor at Oil & Gas Journal. He has also served as a principal technical professional at Halliburton and as a completion engineer at ConocoPhillips. He holds a BS in chemistry (1987) from Kent State University and a PhD in chemistry (1992) from Carnegie Mellon University. He is a member of the Society of Petroleum Engineers (SPE).