CO2 flooding in SACROC improves marginal asset performance

Modified water-alternating-gas (WAG) schemes at Scurry Area Canyon Reef Operators Committee (SACROC) resulted in about 8% tertiary recovery for two marginal projects. Hawaii and East Flank were initially deemed uneconomic for tertiary recovery due to marginal quality pay but were reconsidered based on optimized injection profiles for conformance control, upgraded gas processing, and more reliable production equipment. Injection started in 2017, and both projects have met economic and production goals. Recovery compares favorably with typical 10% yields for higher-graded projects.

CO2 injection redevelopment

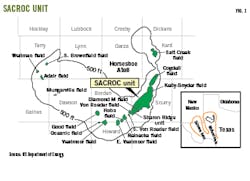

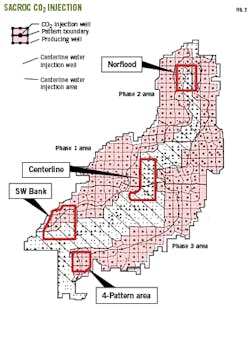

SACROC is in Horseshoe Atoll, on the eastern side of a Pennsylvanian-aged carbonate reef in Midland basin (Fig. 1). In 1971, Chevron started a WAG CO2 pilot injection program in three phases of equal size areas surrounding initial centerline water injection (Fig. 2). Effective CO2 flooding requires that reservoir pressure exceeds CO2 minimum miscibility pressure (MMP). For SACROC oil, MMP is about 1,850 psi. Initial water injection in 160-acre inverted 9-spot patterns (8 producers, one injector) increased reservoir pressure from below 1,600 psi to above 2,400 psi. WAG injection followed, with oil production from Phase 1 increasing to 100,000 b/d from 30,000 b/d.

The rate increase was mostly attributed to water injection, rather than combined water and CO2 injection. A CO2 shortage delayed and ultimately curtailed full WAG into Phase 2 and Phase 3. Also, a substantial amount of CO2 injected into areas of the reservoir was below MPP.

True tertiary response from miscible CO2 flood was identified in 1981 in the 4-Pattern area in the southern part of the field, within the boundary of Phase 3. The 4-Pattern area has estimated OOIP of 28 million bbl of oil (MMbo). Chevron injected about 30% of the area’s hydrocarbon pore volume (HPV) with CO2 in three 160-acre inverted 9-spot patterns and one slightly irregularly shaped fourth pattern. Incremental production was 2.7 MMbo, slightly under 10% of the OOIP, and the results established that SACROC could expect 20% primary recovery, 20% secondary (water flood) recovery, and 10% tertiary recovery.

In 1992, a new operator initiated three CO2 flood projects named Norflood, Center Line, and Southwest Bank. Norflood injected into lower intervals and produced from upper intervals to test vertical permeability. It was not successful. Center Line injected into 40-acre 5-spot patterns in a similar location to the earlier Center Line water flood and was successful. Southwest Bank had conformance problems due to low connectivity between porous zones and fractures in the tighter zones and was not successful.

In June 2000, Kinder Morgan acquired SACROC and took over operatorship. Daily rates of about 8,700 b/d approached the field’s economic limit, and about 40% of OOIP had been produced between primary and tertiary production. Kinder Morgan initiated large-scale CO2 injection in select areas but with key differences from previous WAG projects.

First, to improve areal sweep efficiency and CO2 contact, the projects used inverted 5-spot patterns covering between 40 and 80 acres, depending upon the porosity-thickness of the area.

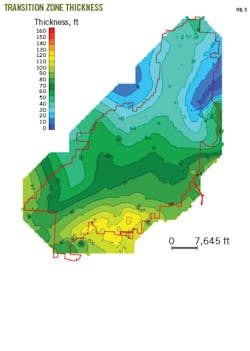

Second, following successful tests at South Shore in 2011, the entire reservoir area including the transition zone was miscibly flooded. The transition zone is the reservoir interval between the producing oil-water contact and the free water level. This zone was bypassed during previous injection, and mapping indicates nearly 380 MMbo of the unit’s OOIP is in this zone (Fig. 3).

Third, WAG schedule was changed to an initial and continuous CO2 slug of around 20-30% hydrocarbon pore volume (HCPV) followed by a tapered WAG schedule of increasing water cut ending in chase water injection. Previous schedules alternated water and gas immediately in fixed volumes. Using the changed schedule, redevelopment projects increased HCPV treated with CO2 to 80-100%.

Lastly, a series of operational and surveillance improvements resulted in better CO2 processing, lower failure rates of artificial lift equipment, and improved injection conformance.

Dimensionless injection

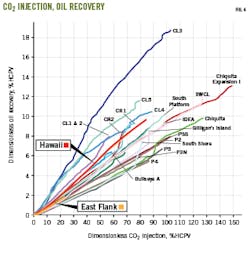

Dimensionless production and injection quantify effectiveness of a CO2 flood and require an OOIP estimate, allocated fluid production, and allocated injection. Dimensionless oil recovery is calculated by converting tertiary cumulative oil production to reservoir volume equivalent, divided by OOIP for the project area. The values can be reliably calculated on a small pattern area but are generally difficult to maintain due to changing pattern geometries over time. It is usually more practical to initially evaluate CO2 recovery over the major project area.

Forecasts usually rely on dimensionless performance curves from offset CO2 floods with similar reservoir characteristics and injection design. Dimensionless type curves translate to production forecasts by estimating average processing rate and OOIP of the entire pay interval from Reef Top to free water level, assuming adequate conformance.

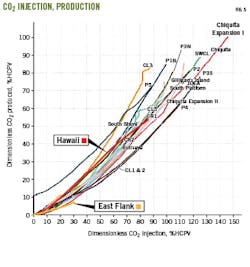

Fig. 4 shows dimensionless injection for major Kinder Morgan SACROC flood operations. Dimensionless CO2 recovery curves plotting dimensionless CO2 injected vs. dimensionless CO2 produced are shown in Fig. 5.

Conformance, surveillance

Poor conformance in CO2 or water flooding can come from mechanical issues such as poor cementing and lack of wellbore integrity, or reservoir geology complications such as natural fractures. The carbonate reef reservoir in SACROC is highly heterogeneous and has lateral and vertical discontinuities of porosity, permeability, and thickness. Direct connections have been observed between injectors and offset producers through preferential pathways and open fractures throughout the field. Breakthrough times were rapid, indicating injected CO2 and oil had not had sufficient time to interact.

The Platform, in northernmost SACROC, contains the thickest floodable targets in the field, with up to 900 ft gross and 700 ft net pay between major reservoir divisions. This highly heterogeneous interval can be further divided into 22 individual geologic layers, and the Green Zone, which contains the highest values of porosity and permeability, is typically first to encounter injection. As a result, substantial reserves in Cisco and Canyon intervals are often bypassed.

SACROC production wells use electric submersible pumps (ESP) which complicate individual well production profiles. Pulling ESPs for production logging tool analysis is not practical or cost-effective. Conformance targets, therefore, are identified by annual injection profiles for each injector and fluid type injected. It is assumed that all production proportionally comes from the same zones in which injection occurs, and an in-house program combines production profiles with allocated production, injection, and OOIP to identify conformance targets. Once a target is identified, the profile analysis is compared with general pattern surveillance and geological interpretations to develop conformance control solutions. These solutions include gel polymer treatments, pressure and rate rebalancing, foamed cement squeezes, multistage cementing, and expandable liners.

Hawaii, East Flank

Hawaii and East Flank CO2 flood expansion projects were not in the original long-range plan for redevelopment of CO2 flooding at SACROC due to marginal quality pay. Also, the 1980-era 4-Pattern area CO2 pilot project was in the Hawaii project boundary and had already produced 10% of OOIP during tertiary recovery, leaving little development potential.

East Flank also originally was deemed marginal with low-quality pay. It contained 63-76% less OOIP/acre than the major development Platform 3 North and Platform 4 projects.

These two expansion projects were approved for development, however, after smaller nearby analogs showed improved oil recoveries when completed through the entire reservoir, including the transition zone, rather than just main pay. Over 30% of Hawaii and 35% of East Flank OOIP is in the transition zone, and new completions extending into this zone required only 4.4% incremental capital over the original South Shore authorization for expenditure.

Further impetus for CO2 flooding came from case histories of modern EOR projects in areas of the field already subjected to significant CO2 injection. As noted for Hawaii, initial project selection avoided previously CO2 flooded areas based on the assumption that those areas had already experienced near-maximum tertiary recovery. Improvements in flood surveillance, however, showed that much early SACROC flooding was below MMP, suggesting high potential for enhanced recovery using modern flood techniques. CO2 floods therefore were implemented in 2017 over a 1,996-acre area in Hawaii and in 2018 over a 2,214-acre area in East Flank. The miscible floods evolved operationally with these larger patterns to reduce development costs greater than those of previous Platform projects.

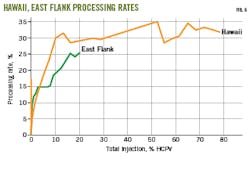

Processing rates—defined as reservoir equivalent CO2 and water injection rate (normalized as an equivalent annual volume) divided by an estimate of the OOIP over the pattern area—were greater than 25% for injectivity above 20% HCPV (Fig. 6), even after accounting for larger patterns at Hawaii and East Flank. Overall dimensionless recovery of Hawaii and East Flank were average for the field (Fig. 4).

Both projects were budgeted to incrementally recover about 8% of the area’s OOIP and to require CO2 injection just under 85% of the HCPV. Hawaii exceeded forecast improved oil recovery (IOR) in less than 3 years and East Flank is following a similar trend.

Based on Kalteyer, J., “A Case Study of SACROC CO2 Flooding in Marginal Pay Regions: Improving Asset Performance,” SPE Improved Oil Recovery Conference, Aug. 31-Sept. 4, 2020.

About the Author

Alex Procyk

Upstream Editor

Alex Procyk is Upstream Editor at Oil & Gas Journal. He has also served as a principal technical professional at Halliburton and as a completion engineer at ConocoPhillips. He holds a BS in chemistry (1987) from Kent State University and a PhD in chemistry (1992) from Carnegie Mellon University. He is a member of the Society of Petroleum Engineers (SPE).