Qatar study allows carbon footprint estimates of particular LNG sources

Eric Johnson

Atlantic Consulting

Zurich

Methods like those used to determine the carbon footprint of crude oil and natural gas from particular reservoirs can also determine the carbon footprint of LNG and LPG from particular sources. Historically, production-to-combustion footprints for crude oil, gas, and related LNG and LPG have been published as an aggregated, single number for a broadly-defined region. More recently, however, oil footprints have been differentiated by region and subregion, resulting in a wide variety of footprints. Gas footprints have been differentiated in a similar way, albeit in less detail. This article shows the same can be done for both LNG and LPG.

LNG production has risen since 1970 at a compound rate of 11% to a 2016 volume of 258 million tonnes. It accounts for about 10% of the world's natural gas, which in turn meets about one-quarter of global energy demand. Strong growth is expected for at least the next decade; another 600 million tonnes/year (mtpy) of specific, potential capacity has already been identified. Most sources of LNG are remote from consuming centers. The largest producer is Qatar, with nearly one-third of output, followed by (western) Australia, Malaysia, Nigeria, Indonesia, and Algeria, which account for about one-half combined.

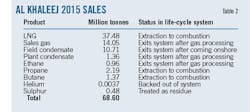

LPG sources have also become more remote. Since the 1990s, production from the Middle East (including Qatar) has tripled. Consumption within the area has also soared, but still the region exports about 40% of its output, making it the world's largest LPG exporter. Increasingly, exported LPG is a co-product of LNG production. For instance, nearly 15 wt % of the hydrocarbon output of the Al Khaleej project in Qatar-the world's largest LNG complex-is propane and butane.

Most of the early studies on LNG's carbon footprint were geographically broad, presenting an average for several producing countries. Some recent studies have covered specific countries. Still, none disaggregated the product slate. In other words, although LNG accounts for only about half of Al Khaleej's hydrocarbon output, these studies publish the footprint as LNG only. In its study, Thinkstep-Nord Stream allocates some of the unit processes among its outputs, but it is unclear whether all fuels are included, and footprints for non-LNG fuels are not reported.

This article allocates the footprint of an LNG plant by unit process and finds footprints for all its fuel outputs, increasing the overall footprint's accuracy. In so doing it also seeks to address growing regulatory concerns regarding LNG's place among competing fuel sources.

Regulators in the European Union (EU) and the US State of California are increasingly interested in the footprints of energy production from specific geographies or production technologies. Whereas most footprint data for oil and gas are very generalized, say, a West European crude oil mix, regulators realize that specific locations can generate wildly varying footprints. The European Union and California have built this variance into their regulatory frameworks. The EU's Fuel Quality Directive now lists footprints of some 600 types of geographically-specific crude oil. The California Air Resources Board lists about 200 different crudes.

By contrast, neither the EU nor California offer much differentiation on gas, LNG, or LPG. This article intends to generate an LNG-LPG footprint specific to Qatar, allocating this footprint by process to its fuels. This analysis could be replicated for other producers.

Just as biofuels now report a footprint for each specific barge- or ship-load, fossil fuels will increasingly be required to do the same.

Method

The primary objects of this footprint study are LNG and LPG produced in Qatar and consumed in the UK. The UK is a major consumer of Qatari LNG and a reasonable proxy for Western European consumption in general. At various times, the UK and Western Europe also have been major consumers of Qatari LPG. Their imports from Qatar vary, however, and have declined with the rise of shale-gas driven imports from the US.

The primary reporting unit is grams carbon dioxide equivalent per megajoule of consumed fuel at higher heating value (CO2e/MJ HHV). The carbon footprints presented in this article were calculated in accordance with Publicly Available Standard (PAS) 2050.

The inventory starts with construction of gas wells in the Persian Gulf, processing of that gas and conversion to LNG at Al Khaleej in Qatar, and transport to and consumption in the UK.

Production

Qatari exploitation of North field in the Persian Gulf is directed by Qatar Petroleum. LNG production is managed by two companies, majority-owned by Qatar Petroleum, Qatargas and RasGas, which merged into one subsidiary in early 2018 (OGJ Online, Jan. 4, 2018).

From 2012-16, Qatar produced 77 mtpy of LNG, about one-third of global output, split almost equally between Qatargas and RasGas. In mid-2017, Qatar Petroleum announced that by 2024 it would increase its LNG output to 100 mtpy.

Based on a RasGas sustainability report, plus other key sources of Qatari LNG composition data (including the US Energy Information Adminsitration) and Qatari raw gas composition data from Attarakih, the author estimated gross and net output at Al Khaleej in 2015. Gross minus net equals internal consumption plus waste.

This output provides the framework for the rest of the carbon footprint estimation. It represents half of Qatar's actual LNG production and is a reasonable proxy for the other half (produced by QatarGas) given the similarity in the two companies' operations.

Nearly half of Qatari LNG is exported to the Pacific Rim, while most of the other half is shipped to Europe and Asia. Sales gas is sold by pipeline within the United Arab Emirates. Ethane is sold locally as steam-cracker feedstock. Propane and butane are either cracked or shipped out as LPG, mainly to Europe and the Pacific Rim. Condensate is sold to refiners, both regionally and abroad.

LNG-LPG supply chain

Production at Al Khaleej (Table 1) provided the basis for supply chain mapping, with inputs and outputs from each of 12 processes estimated.

Exploration and well construction in Qatar's portion of the Persian Gulf's North field began in the early 1970s. Direct input-output data on the exploration of the field and the construction of these wells are not available. Of the four LNG-footprint studies that specifically cover Qatar, only one of them, Tagliaferri, explicitly reports covering exploration and production. To do this, Tagliaferri used data from Ecoinvent, which rolls exploration and construction together with production. This article uses a more recent, detailed source, National Energy Technology Laboratory (NETL), that breaks out exploration and construction separately from production.

Hydrocarbons processed at Al Khaleej are produced in North field via gas wells connected to above-water platforms. The gas mixture flows by its own pressure to the surface, but keeping the well in operation generates some emissions. After the gas comes to the surface, the raw stream is treated at the platform to remove some of the heavier hydrocarbons (C5+, often called field condensate) and water. The field condensate is pumped in a wet pipeline to shore, because it would condense in the dry pipeline that transports the rest of the mixture to shore. The water is removed.

Direct input-output data on production and transport of hydrocarbons to Al Khaleej are not available. Again, this article turned to NETL's most recent detailed data for production and transport. Its data cover production operations, compression and injection to the pipeline, flaring, and dehydration. The author has added the relevant footprint data from Ecoinvent for production of triethylene glycol, used as a sorbent-desorbent in dehydration.

Gas processing

When the gaseous hydrocarbons come onshore at Al Khaleej, the heavier hydrocarbons are separated and the lighter ones are processed to remove carbon dioxide, nitrogen, and especially sulfurous compounds. LNG has a lower tolerance than gaseous natural gas of contaminants and hydrocarbons with freezing points above that of methane's condensation, requiring more processing. Water and carbon dioxide, for instance, will turn to ice in LNG, which can foul pumping, piping, and processing.

Direct input-output data on processing at Al Khaleej are not available. Of the four LNG-footprint studies that specifically cover Qatar, only Tagliaferri explicitly reports processing as disaggregated, but its data source is unclear.

Other sources report general input-output data for processing. This article applied an average of these excluding International Gas Union, data from which was impossible to interpret accurately. The inputs-outputs include venting of carbon dioxide.

This article treats sulfur produced from gas processing (0.48 million tonnes in 2015) as a residue in the footprint calculations and it is not allocated any of the emissions. It is not a waste, because it has market value. It is an unavoidable by-product.

Liquefaction, flaring

Direct input-output data on liquefaction at Al Khaleej are not available. Several studies report disaggregated figures for liquefaction. Thinkstep-Nord Stream is specific to Qatar and the others are more general. This article applied an average of these. Added to this is a loss rate for LNG plants of 0.05% reported by DG Energy European Commission.

Energy and material inputs from NETL and footprints from Ecoinvent for delivered energy and materials allowed inventory of input and outputs from construction of the liquefaction plant.

Flares run at the offshore production platforms, at onshore storage and production sites, and in loading areas. Their main purpose is to get rid of excess feedstock or boiloff gas (from LNG) safely. For instance, if the LNG plant goes down for maintenance, the input gas is flared. Flares also sometimes are used to dispose of off-specification product, which for economic reasons are kept to a minimum.

RasGas reports flaring gas in 2015 that emitted 0.93 million tonnes CO2. RasGas's report and a review of other literature about LNG-related flaring (for instance, documents from The Global Gas Flaring Reduction Partnership), make it clear that most Qatari LNG flaring is onshore. The author estimates 90%. Estimated flaring at production is unchanged and all other processes through to loading are assessed a flaring total of 90% x 0.93 million tonnes CO2 or 0.84 million tonnes.

According to RasGas, between 2007 and 2015 the acid-gas injection (AGI) site moved more than 9 million tonnes of CO2 into a saline aquifer. This works out to approximately 1 mtpy, credited back against the well-to-ship footprint, i.e. the footprint created in Qatar. The credit has been applied to all fuels produced at Al Khaleej, allocated by energy content.

RasGas extracts helium from the gas mixture for commercial sale. Production in 2015 was 3,700 tonnes, about 0.01% of RasGas's annual output. The volume is so insignificant, it has not been considered in process yields. But the emissions generated to remove it have been backed out of the well-to-ship total.

Helium is backed out, rather than allocated its negligible portion of upstream emissions, because it is not a fuel. It also is not a residue, which is why its extraction is backed out, rather than allocated to the main products.

After processing and liquefaction, dedicated transportations systems move LNG and LPG into temporary storage and then load it onto an ocean-going ship. All products exit the lifecycle footprint system at this point except LNG, propane, and butane (Table 2). The other products could be studied from gate-to-stack.

Most LNG footprint studies aggregate storage and loading together with other processes. Delphi Group reports data for storage and loading in Australia. Qatargas reports loading emissions, but does not provide any way to normalize them, so they are not useful in this context.

This article applies the much more detailed data reported by Thinkstep-Nord Stream. A particularly important issue in LNG storage and loading is the boiloff rate of LNG and the fraction of boiloff gas recaptured and either flared or used as fuel. These have been accounted for in the Thinkstep-Nord Stream data.

Applying anonymized unpublished data collected by the author for LPG terminals in six countries in Europe and the Middle East allowed estimation of the LPG storage and loading footprint. Most of the emissions are from electricity generation and the carbon emission factor/kWh in Qatar is applied.

Ship transport

LNG travels via ship from Al Khaleej to Milford Haven, one of the UK's three LNG-import terminals and a major British destination for Qatari LNG. The ships return empty to Qatar.

Studies have reported ocean-going transport footprints of LNG. The footprints vary threefold, ranging from 2.2-6.8 g CO2e/MJ LNG. Given the large range, this study applied data from Tagliaferri as the most recent, peer-reviewed, and specific to Qatar. It is presumed that 2.5% of the loaded LNG is lost to boil-off during the 14-day voyage.

LPG transport emissions are taken from Ecoinvent, with the assumption that the product is shipped from Al Khaleej to Milford Haven, one of the UK's 15 LPG terminals.

Storage, regasification

Upon arrival in the UK the LNG remains in storage until it is demanded for redelivery. At that time, it is pumped from the tanks and subjected to both heat and pressure to return it to a gaseous state for transportation by pipeline. The heat and pressure are provided by gasified LNG, quantities of which are reported by UK Dept. of Energy & Climate Change and UK Dept. for Environment, Food & Rural Affairs (DEFRA). These factors have been used to calculate the emissions and the yield loss.

LPG terminalling applied anonymized, unpublished data collected by the author for LPG terminals in six countries in Europe and the Middle East. Most of the emissions are from electricity generation, with the carbon emission factor per kWh in the UK applied.

UK transport, distribution

Determining the footprint of domestic UK LNG transport uses recent, peer-reviewed data specific to the UK. This transport footprint is 6% lower than a generic one for Europe published by DG Energy European Commission and 19% higher than one for Germany published by DBI Gas- und Umwelttechnik GmbH.

LPG emissions are taken from anonymized, unpublished data collected by the author for approximately 50% of LPG distribution in the UK.

Combustion

End users combust the LNG and LPG mainly for heat, but also to some extent to power transport. Emissions for combustion of LNG and LPG are taken from the UK government's official guidance. These have been applied in this article on a straight higher-heating-value basis, i.e. they have not been adjusted for equipment or vehicle efficiencies.

Footprint results

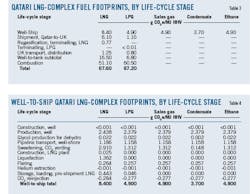

The author calculated footprints well-to-stack for LNG and LPG and well-to-ship for the other fuels (Table 3). LNG's well-to-tank (WTT) footprint is more than twice as high as LPG's because of higher emissions in gasification, transport, and regasification. This is almost completely offset by LPG's higher combustion emissions, resulting in almost identical well-to-stack footprints for the two.

Analysis of the well-to-ship footprints used 11 subprocesses (Table 4). LNG comes out with the largest footprint for three reasons:

• It must be sweetened more than the other fuels because higher-freezing point compounds can turn into ice during liquefaction, which cannot be tolerated in the subsequent delivery chain.

• It must be liquefied.

• There is an overall yield loss in LNG across all the subprocesses.

Condensate has the smallest footprint because it requires the least processing.

Comparisons

Table 5 compares the LNG footprints in this article with those of similar studies. This study's WTT footprint of 16.5 g CO2e/MJ HHV is 10-17% more than that of two recent studies, but one-third lower than Tagliaferri, a peer-reviewed study specific to Qatar-UK LNG. The biggest difference is in the well-to-ship segment, but the data are not detailed enough to allow further explanation.

This article's WTT footprint is also lower than that of the UK Dept. for Business, Energy and Industrial Strategy (BEIS), which is specific to UK LNG but not necessarily from Qatar, and that of the European Commission (EC), which is a generic figure for LNG to Europe. This article's findings also differ significantly from Tamura's historic figure for LNG to Japan, which is understandable given the differing temporal and regional conditions.

Less understandable is the difference to the footprint reported by RasGas, which is considerably below all others. The author queried RasGas about this by email in June 2017. A spokesperson from RasGas acknowledged the query and promised a reply, but by completion of this article none had been received.

Imported LPG footprints have no direct comparators, but those in this article are compared in Table 6 to other LPG footprints. The UK government's figure is 18% higher than this article's but there is no detail in their estimate to explain why. The US Dept. of Energy's Office of Energy Efficiency and Renewable Energy Argonne's Greenhouse gases, Regulated Emissions, and Energy use in Transportation (GREET) figure is 74% higher, but has a different basis: a significant proportion of the production is from shale gas, which reports much higher emissions (according to GREET) than LPG produced from conventional gas onshore or offshore.

The refinery LPG footprints from GREET, Tiax LLC, and Jacobs Consultancy are presented in additional comparison. The difference in gas and refinery LPG footprints is a worthwhile topic for further analysis.

A logical extension of this work would be to conduct similar analyses for other major LNG (and LPG) producers such as Australia, Malaysia, Nigeria, Indonesia, and Algeria. A preliminary review of the literature suggests that LNG footprints from some of these locations might be substantially greater than those of Qatar.

Bibliography

Advanced Resources International, ICF International, "Fuel Life-Cycle of US Natural Gas Supplies and International LNG," 2008.

Argonne National Laboratory. GREET 2015, 2015.

Atlantic Consulting, 2014, "A comparative Environmental Impact Assessment of car-and-van fuels: petrol, diesel, LPG & CNG," 2014.

Attarakih, A., Abu-Khader, M., Saieq, T., and Bart, H.J., "Ethane production plant for better energy integration and cost reduction in Jordan," Journal of Chemical Technology and Metallurgy. Vol. 48, No. 3, 2013, pp. 265-276.

Beer, T., Grant, T., Morgan, G., Lapszewicz, J., Anyon, P., Edwards, J., Nelson, P., Watson, H., and Williams, D., "Comparison of transport fuels: Final report to the Australian Greenhouse Office," 2001.

BSI, Carbon Trust, UK DEFRA, PAS 2050, "Specification for the assessment of the life cycle greenhouse gas emissions of goods and services," 2011.

California Air Resources Board, "Calculation of 2016 Crude Average Carbon Intensity Value," 2017.

CEFIC, ECTA, "Guidelines for Measuring and Managing CO2 Emission from Freight Transport Operations," 2011.

DBI Gas- und Umwelttechnik GmbH, "Critical Evaluation of Default Values for the GHG Emissions of the Natural Gas Supply Chain," 2016.

DECC, DEFRA, "Guidelines to Defra / DECC's GHG Conversion Factors for Company Reporting," 2010.

Delphi Group, "LNG Emissions Benchmarking," 2013.

DG Energy European Commission, "Actual Ghg Data for Diesel, Petrol, Kerosene and Natural Gas," Brussels, 2015.

European Commission, "Methodology for the calculation and reporting of the life cycle greenhouse gas intensity of fuels and energy by fuel suppliers," Annexes 1-4 of the Fuel Quality Directive, 2014.

Faist-Emmenegger, M., Heck, T., and Jungbluth, N., Erdgas, Ecoinvent Report No. 6-V, 2007.

International Gas Union, "2017 World LNG Report," 2017.

International Gas Union, "Life Cycle Assessment of LNG, 2012-2015," Triennium Work Report, 2015.

International Maritime Organization, "Second IMO GHG Study 2009," International Maritime Organization, London, 2009.

Jacobs Consultancy, "LCA of North American and Imported Crudes," Alberta Energy Research Institute, 2009.

Johnson, E.P., "Carbon footprints of heating oil and LPG heating systems," Environmental Impact Assessment Review, Vol. 35, 2012, pp. 11-22.

Joint Research Centre of the EU Commission, EUCAR, CONCAWE, "Well-to-Wheels analysis of future automotive fuels and powertrains in the European context," 2006.

MARCOGAS (Technical Assocication of the European Natural Gas Industry), "Life Cycle Assessment of the European Natural Gas Chain focused on three environmental impact indicators," 2011.

Muñoz, I. and Schmidt, J.H., "Methane oxidation, biogenic carbon, and the IPCC's emission metrics: Proposal for a consistent greenhouse-gas accounting," International Journal of Life Cycle Assessment," Vol. 21, No. 8, August 2016, pp. 1069-1075.

Myhre, G., Shindell, D., Bréon, F.M., Collins, W., Fuglestvedt, J., Huang, J., Koch, D., Lamarque, J.F., Lee, D., and Mendoza, B., "Anthropogenic and natural radiative forcing," Climate Change 2013: The Physical Science Basis, Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, 2013, pp. 659-740.

National Energy Technology Laboratory, "NETL Life Cycle Inventory Data LNG Liquefaction Plant Construction," 2013.

National Energy Technology Laboratory, "NETL Life Cycle Inventory Data Natural Gas Well Construction and Installation (conventional offshore)," 2010.

National Energy Technology Laboratory, "NETL Life Cycle Inventory Data Extraction of natural gas from a conventional offshore well," 2010.

National Energy Technology Laboratory, "NETL Life Cycle Inventory Data Natural Gas Sweetening, Amine Process Acid Gas Removal," 2010.

National Energy Technology Laboratory, "NETL Life Cycle Inventory Data LNG Liquefaction, Operation," 2010.

Okamura, T., Furukawa, M., and Ishitani, H., "Future forecast for life-cycle greenhouse gas emissions of LNG and city gas 13A," Applied Energy, Vol. 84, No. 11, November 2007, pp. 1136-1149.

Pace Global, "LNG and Coal Life Cycle Assessment of Greenhouse Gas Emissions," 2015.

Psaraftis, H.N. and Kontovas, C., "CO2 Emissions Statistics for the World Commercial Fleet," WMU Journal of Maritime Affairs, Vol. 8, No. 1, January 2009, pp. 1-25.

Qatar Petroleum, "Annual Review 2015," 2016.

Qatargas, "Sustainability Report 2015," 2015.

RasGas, "Sustainability Report 2015," 2016.

SHV Energy, "SHV Energy Carbon Count 2013," Hoofddorp, Netherlands, 2013.

Skone, T.J., Littlefield, J., Marriott, D.J., Cooney, G., Jamieson, M., Hakian, J., and Schivley, G., "Life Cycle Analysis of Natural Gas Extraction and Power Generation," DOE NETL, 2014.

Tagliaferri, C., Clift, R., Lettieri, P., and Chapman, C., "Liquefied natural gas for the UK: a life cycle assessment," International Journal of Life Cycle Assessment, Vol. 22, No. 12, December 2017, pp. 1944-1956.

Tamura, I., Tanaka, T., and Kagajo, T., "Life cycle CO2 analysis of LNG and city gas," Applied Energy, Vol. 68, No. 3, March 2001, pp. 301-319.

Thinkstep-NGVA, "Greenhouse Gas Intensity of Natural Gas," 2017.

Thinkstep-Nord Stream, "Greenhouse Gas (GHG) Intensity of Natural Gas Transport," 2017.

TIAX, "Comparison of North American and Imported Crude Oil Lifecycle GHG Emissions," Alberta Energy Research Institute, 2009.

UK DEFRA, "UK Government GHG Conversion Factors for Company Reporting," 2016.

UK Department of Business Energy & Industrial Strategy, "2016 Government GHG Conversion Factors for Company Reporting: Methodology Paper for Emission Factors," 2016.

UK Department of Energy & Climate Change, "Energy Trends," 2014.

US Department of Energy, "Lower and Higher Heating Values of Fuels," 2010.

US Energy Information Administration, "Liquefied Natural Gas: Understanding the Basic Facts," 2005.

Worley Parsons, "Greenhouse Gas Emissions Study of Australian CSG to LNG," 2011.

The author

Eric Johnson ([email protected]) is managing director of Atlantic Consulting, editor-in-chief emeritus of 'Environmental Impact Assessment Review' and refining-chemicals editor for 'Ecoinvent.' He is based near Zurich, Switzerland, and has worked in and around the energy and chemicals industries for 35 years. Switzerland's federal government has nominated him as an Intergovernmental Panel on Climate Change assessor of greenhouse-gas emission inventories.