Regressions allow development of compressor cost estimation models

View Article as Single page

Capacity differences

Coefficient results show cost is also related to compressor station size. All costs show a relationship to both compressor station capacity and compressor station capacity square (sq hp) except land cost, which only shows relationship to compressor station capacity square.

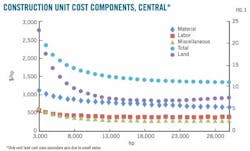

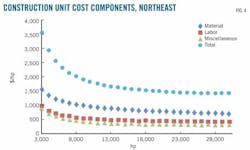

Figs. 2-7 show the trend of compressor station construction cost components as related to compressor station capacity in different regions.

Fig. 2 illustrates compressor station unit total cost in the US decreasing as compressor station capacity increases. This trend suggests the total cost has economies of scale with respect to compressor station size. For example, the unit total cost of a 2,000-hp compressor station is 3.2 times that of 30,000-hp compressor station. A similar trend exists in unit costs of material, labor, miscellaneous, and land.

Figs. 2-7 show the estimated unit cost trend of cost components in the Central, Northeast, Southeast, Midwest, and Western regions. All individual component unit costs decrease with increasing compressor station capacities in different regions. Analysis concludes all cost components as having economies of scale with regard to compressor station capacity in all regions.

Economies of scale caused by growth of the project itself are called internal economies of scale. Increasing compressor station size can produce internal economies of scale for compressor station projects. Technical economies, managerial economies, marketing economies, and financial economies are considered four major categories of internal economies of scale.11

Specialized equipment or processes improve labor and capital productivity in large pipeline projects. For example, large and efficient trenchers and trucks increase productivity and reduce the cost of diesel. Small compressor station projects cannot afford heavy equipment costs because they cannot diffuse the high fixed cost. Large equipment and facilities are also easily operated in high capacity with less idle capacity.

Managerial economies of scale have large compressor station projects hiring more professional and specialized managers to perform specialized tasks with skill and productivity instead of hiring one manager in charge of everything. Marketing economies can realize a large discount by purchasing a large amount of compressor station promotional material. Large compressor station projects being more likely to be awarded low interest rate loans or government subsidies is an examples of financial economies of scale.

These factors support the idea that large compressor station projects have economies of scale and low unit cost and match regression results showing unit costs of compressor station construction components falling with increasing compressor station size.

Displaying 4/5

View Article as Single page