COMPRESSOR OPTIMIZATION—1: Energy recovery guides natural gas pipeline system efficiency

View Article as Single page

Energy lost through a station's chimney reduces gas turbine thermal efficiency. Studying the polytrophic efficiency and consumption power of compressors also showed potential to save large volumes of fuel gas (Table 9).

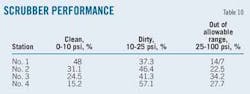

Table 10 shows scrubber performance.

Energy consumption

This article initially outlined existing energy consumption norms in gas pipelines and describED essential parameters and criteria for comparing operational conditions with design conditions and optimum conditions. It then discussed the potential energy savings found in each compressor station component. It will now turn to available means for realizing these savings and an economic analysis of the results.

Gas turbines

Methods for energy savings and recovery in compressor stations' gas turbines include:

• Using a recuperator.

Air entering a combustion chamber is preheated by hot air leaving the turbine and entering a recuperator. This system, however, is suitable only for gas turbines with low power and low pressure ratios. High-pressure turbines suffer from low efficiency when using a recuperator since the pressure loss is greater. Recuperators could only operate at those Iranian compressor stations using Nevsky systems.

• Cooling the input air.

• Recovering energy lost through the chimney.

• Replacing the gas turbine.

Inlet air

Practical methods for cooling a compressor station's inlet air include:

• Direct evaporation system.

• Absorption, mechanical chillers.

• Underground channels.

Table 11 summarizes the effects of each on Siemens compressors.

Cooling the inlet air has a negligible effect on system efficiency, and is suggested only for stations facing operational limitations in hot months of the year.

In-chimney recovery

Either a Kalian cycle or organic Rankine cycle (ORC) chimney unit can recover energy from the chimney.

• Kalian cycle is useful when the exhaust-gas temperature from the chimney is low, limiting possible energy recycling. In Iran such conditions occur only when using Nevsky gas turbines. Since these turbines have very low efficiency, however, they are not good candidates for energy recycling equipment and should instead be replaced by higher-efficiency turbines.

Table 12 summarizes Kalian cycle's effect on Nevsky units under design conditions. The authors do not recommend their use. ORC cycle is the best energy recovery solution. Fluid selection is based on gas turbine conditions, local conditions, and the technology used by the manufacturer. But average ORC cycle efficiency at compressor station chimney temperature is about 10%. The low temperature in Nevsky gas turbine chimneys, however, precludes use of the ORC cycle on efficiency grounds.

Calculations show recoverable power in compressor stations using ORC cycles of about 120 kw/hr. Since the recovered energy in the ORC cycle is electrical and electric energy use in compression stations is low, the saved electric energy is best used to start another gas compressor by electric motor.

Displaying 4/5

View Article as Single page