COMPRESSOR OPTIMIZATION—1: Energy recovery guides natural gas pipeline system efficiency

View Article as Single page

Turbine replacement

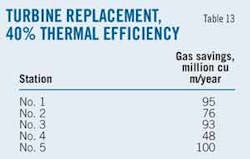

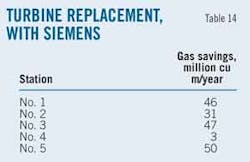

Gas turbines normally operate at lower efficiency than their design condition. Reconstructing compressor stations and replacing gas turbines can increase thermal efficiency. This article considers two turbine replacement scenarios. Table 13 shows energy savings stemming from replacing existing turbines with units having 40% better thermal efficiency. In the second scenario, Siemens turbines replace the existing units, resulting in the energy savings shown in Table 14.

Feed cooling

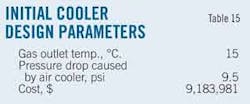

Cooling a compressor station's gas feed can decrease its power requirement. Either a chiller or an air cooler can cool the gas feed. Preliminary calculations show a chiller uses too much energy to be economical. Table 15 shows general specifications of an air cooler used in cooling a compressor station's gas feed.

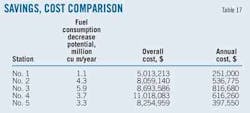

Table 16 shows the reduced power needs and fuel requirement realized by using an air cooler for a year, given that the ambient temperature is cooler than the gas feed. Table 17 shows the cost savings potential achieved by using air coolers at five other stations in differing climates.

The author

Displaying 5/5

View Article as Single page

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com