By OGJ editors

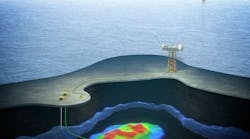

HOUSTON, July 2 � Statoil ASA's development and use of a new compact in-line separation at its Sleipner T platform in the North Sea has improved recovery from the field, the company said, and the new technology holds promise for improving production from other deepwater subsea developments in producing fields, possibly making platforms unnecessary in the longer run.

The technology also could reduce carbon dioxide emissions from existing offshore platforms by as much as 50%, Statoil said, compared with existing technology.

Statoil, which developed this method in cooperation with the offshore supplies industry, said it has achieved success with a prototype installed last September to separate liquid from gas. The company plans to install similar equipment on its Statfjord B platform further north this autumn.