Seismic stimulation improves production from West Texas carbonate

Jeff Marshall

Abraxas Petroleum Corp.

San Antonio

Sergey Kostrov, Bill Wooden

Applied Seismic Research Corp.

Plano, Tex.

A project on a West Texas lease shows the effectiveness of seismic stimulation to arrest oil production rate decline of a nonwater-drive carbonate reservoir.

As worldwide demand for oil increases, oil companies are employing costly methods such as gas injection, chemical injection, and thermal techniques to enhance oil production in large oil fields. In smaller fields, however, these methods, including waterflooding, are often too costly, leaving operators few options to enhance recovery.

The US has an abundance of small oil fields. These fields contain more than 340,000 wells, many producing less than 5 b/d; yet in total these fields produce 260 million bbl/year. The country, therefore, has an untapped potential for increased oil production from small oil fields. The question is what method can be applied to economically enhance oil recovery?

This article covers seismic stimulation for enhancing oil production from a carbonate on Abraxas Petroleum Corp.'s Bishop-Huddleston lease in West Texas.

Waterflooding is a viable option for this lease. Abraxas, however, wanted a less expensive EOR method to recover additional resources. Hence, it chose seismic stimulation because the technology:

• Has zero environmental effects.

• Requires no specialized transport or implementation.

• Stimulates production across many faults and horizons.

• Most importantly, is reliable and inexpensive.

In addition, seismic stimulation has proven effective on diatomite, sandstone, and carbonate reservoirs. The Texas Railroad Commission also certifies it as an official EOR process, thus granting Texas operators a 50% severance tax reduction for 10 years.

Seismic stimulation tool

A conventional pumping unit powers Applied Seismic Research's (ASR's) tool for creating downhole high energy, seismic stimulation shockwaves.

One can install the tool at 700-10,000 ft depths in abandoned wellbores or active injection wells using a perforated sub. The wellbores need to have 5.5 in. or greater IDs.

Tool life span ranges from 8 months to greater than 1 year, depending on wellbore and fluid conditions.

ASR ships the tool in three preassembled sections in a 2 by 2 by 25 ft container. Installation of the tool is similar to a tubing pump. Tool operation requires no major maintenance.

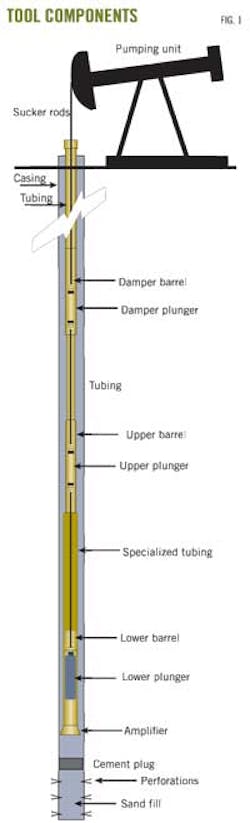

Fig. 1 shows the tool's components. At the bottom of the well, sand fill covers the perforations. Above the sand fill, a placed cement plug prevents gas from entering the wellbore. Gas entry would cause the tool to misfire.

Acoustically, cement is similar to carbonates and the shockwaves do not lose significant power as they pass through the plug.

The shockwaves travel at more than 1.5 miles/sec and compress and release only a small amount of water; hence, the momentum of the traveling wave fronts is so small that they will not damage the cement bond or wellbore integrity.

An amplifier at the bottom of the tool, with a similar design to a rocket nozzle, increases the velocity and modifies other characteristics of the shockwaves.

The lower plunger contains a traveling valve to bring fluids in. When it reaches the top of the stroke, it exits the lower barrel to release instantaneously the highly compressed fluids, thus creating the hydroimpact shockwave. Specialized tubing acts as a compression chamber.

Displaying 1/5 Page1, 2, 3, 4, 5Next>

View Article as Single page