TRINIDAD EOR—1: More than 1 billion bbl of heavy oil remain onshore

| Based on a presentation to PennWell's Oil Sands and Heavy Oil Technologies Conference, July 20-22, 2010, Calgary. |

Raffie Hosein

Wayne Bertrand

Richard Dawe

University of West Indies

St Augustine, Trinidad

Enhanced oil recovery processes have the potential for producing substantial amounts of heavy oil in Trinidad.

This first in a series of two articles on EOR in Trinidad will discuss the potential for producing the 1 billion bbl of heavy oil in place contained in onshore reservoirs. Besides the heavy oil onshore, Trinidad also has an estimated 2 billion bbl offshore. The concluding article will cover the potential for recovering these offshore resources with carbon dioxide injection.

Heavy oil production in Trinidad started more than 100 years ago and estimates to date are that only 20% of the 1.5 billion of initially in place onshore resources have been recovered.1

Currently heavy oil contributes about 30% (36,000 bo/d) of the country's total oil production of about 110,000 bo/d. Production from the onshore fields is about 16,000 bo/d of which 70% is by primary recovery with the remaining coming from 20 steamfloods and water alternating steam process (WASP) projects by steamflooding.2

Resource

The island of Trinidad lies north of the Orinoco River's mouth in the eastern Venezuelan basin (Fig. 1a).

Most of Trinidad's oil is classified as heavy oil with 30,000-10,000 cp viscosity and 10-22° gravity (OGJ EOR surveys 1992-2010).1 2

Onshore reservoirs contain about 1 billion bbl in the southern basin (Figs. 1b and 1c) and about 2 billion bbl offshore in the southwestern basin.

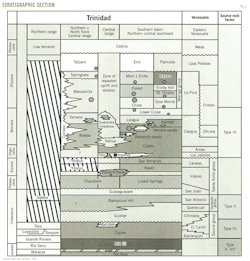

These oil reservoirs are late Tertiary sandstone structures of Miocene and mainly Pliocene age (Fig. 2).

Trinidad's geology is complex and often referred to as a geologist's nightmare. This makes it difficult to estimate oil in place and recovery.

Tectonic activities within the Miocene and Pliocene created a series of faulted anticlines, which form the main structural framework for oil accumulation and tar-sands deposits from source rocks such as the Gautier and Naparima Hill formations and possibly the Cuche of Cretaceous (145-65 my) age.3 4 Northeast-southwest thrust faults and northwest-southeast trending normal faults act as flow barriers, forming separate hydrocarbon accumulations with different formation pressures and oil-water contacts.

Lenticular sand bodies also are prominent within this deltaic setting. The primary fault is a right-lateral wrench slip Los Bajos fault (dotted lines in Fig. 1c ) that runs southeast across the southwest of the island and provides vertical migration pathways for oil and gas.5

The onshore heavy oil reservoirs are at 300-3,000 ft depths. These reservoirs are mainly in the Upper and Lower Morne L'Enfer (UMLE and LMLE), Forest, and Cruse formations of Pliocene age (Fig. 2).4

The reservoirs consist of poorly consolidated sand with varying degrees of silt and dispersed clays and often have high >20% porosity, high >25% water saturation, and a 250-md average permeability. The reservoirs produce sand and contain interbedded shale laminations.6 The depth and fluid properties make the reservoirs ideal candidates for steam injection.

The period 1965-2004 saw 20 steam-injection projects implemented.2 Some encountered technical problems, and three projects proved unsuccessful.

Even so, estimated recoveries from these projects nearing completion approach 70%.6

Steam injection

The first steam-injection project in Trinidad started in 1963 in Penal-Wilson field to recover a 15° gravity oil by cyclic stimulation in six wells.6 The project was aborted after 1 month of steam injection because parted casing caused the wells to produce a mixture of mud, water, and emulsion.

By 1995, 17 steamflood projects had been implemented in Trinidad.2 Nine major projects were in Point Fortin Parrylands, Point Fortin Cruse E, Guapo, Forest Reserve, Fyzabad, North Palo Seco, Central Los Bajos, Bennett Village, and Apex Quarry fields. These fields contain the bulk of the onshore heavy oil reserves (Fig. 1c).6

From 1995 to the present, three other projects started.

Table 1 shows the location, start date, and evaluation of these projects.

Initial steam injection was cyclic (a soak period of about 2 weeks and production periods up to 6 months) in Forest Reserve, North Palo Seco, Guapo, Central Los Bajos, and Fyzabad fields. This was followed by continuous steam injection or steamflood.

Pilot projects in the Forest Reserve Project 111, Forest Reserve UMLE, North Palo Seco and Cruse E fields led to expansions.6

The Petroleum Oil Co. of Trinidad and Tobago (Petrotrin) has operated 19 steamflood projects, while a lease operator operates the Parrylands Block E project.

Reservoir properties

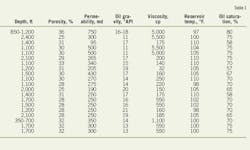

Most of the heavy oil reservoirs are at a shallow 300 ft to about a 3,000 ft depth in the Upper and Lower Morne L'Enfer, Forest, and Cruse formations (Table 1). Sand thickness varies from 90 to 175 ft.2 7

The Morne L'Enfer sands are at 1,200-1,700 ft with not much variation in porosity (average 28%) and permeability (average 250 md).

The Forest sands are at 350-1,500 ft, with 28-33% porosity and 200-750 md permeabilities.

The Cruse sands are deeper at 1,400-2,400 ft with 25-31% porosity and 95-300 md permeability.

The heavy oil under steam injection has 11-21° gravity and 32-5,550 cp viscosity at reservoir temperatures (Table 1).2

Oil formation volume factors are 1.1-1.3 reservoir bbl/stock-tank bbl and the GOR is 100-400 scf/stock-tank bbl.

At the beginning of steam injection, the reservoirs had a 60-80% oil saturation.

Screening criteria

Table 2 summarizes the fluid and rock properties for steam injection projects. Apart from the Cruse E field with a 95-md permeability all the other fluid and rock properties are within the screened range outlined by Taber et al.8

Projects with areas less than 60 acres (mainly the Forest sands), however, were not profitable and were discouraging (Table 1).

Heavy oil production

Trinidad's highest average heavy oil production from steam injection was slightly more than 10,000 b/d from 17 projects in 1991 (Fig. 3). Most of this production came from Forest Reserves Project III, North Palo Seco, Guapo, Central Los Bajos, North Fyzabad, Apex Quarry, Parrylands, Bennett Village, and Cruse E pilot fields.

Many ongoing problems with steam injection related to well placement and no connectivity between the injector and producer because of complex geology. Other problems included steam gravity override, early steam breakthrough, steam channeling, mechanical problems, heat losses, and a water shortage.

In other cases, the operator stopped steam injection because of environmental concerns as well as for cost savings.

For 1997, the effect of low oil prices (Brent crude was under $10/bbl in June 1999) and the high cost of natural gas as a fuel for steam generation led to the conversion of six mature projects (North Fyzabad, North Palo Seco, Apex Quarry, Central Los Bajos, Bennett Village, and Forest Reserve Project 111) into a water-alternating-steam process (WASP) to save costs and to reverse oil production decline.9

WASP effectively controlled steam breakthrough,10 maintained reservoir pressure, improved thermal efficiency, sustained oil production in fields with declines, and reversed uneconomic flood patterns into profitable ones because of increased oil production and reduced operating cost.11

In 2010, steam and WASP produced about 5,000 b/d in Trinidad. Despite the decreases since 1991, which were related to various problems, an evaluation of Trinidad's steam injection projects shows that 11 have been successful, 5 promising, 1 too early to tell, and 3 discouraging (Table 1). The discouraging ones have areas less than 60 acres.

The Forest Reserve Project 111 and Fyzabad projects are nearing completion and have 68 and 42% recoveries, respectively.

Monitoring practices

Geology is the single most important factor that determines the success of an EOR operation, but this factor is difficult to apply because of the geologic complexity.

EOR processes that involve steam or gas injection will have gravity segregation followed by channelling and early breakthrough.

Simple useful monitoring indicators include steam volumes injected and produced, oil and water production, average reservoir pressure, and fluid maps such as isothermal, isobaric, isosalinity, isopack, isogross, net rates, isocummulative production, and isowater-cut maps. These indicators are useful for determining migration paths and fluid accumulation, infill drilling locations, and flood pattern reorientation for production optimization.

Also a decision to continue, expand, or terminate a project should not be based only on performance but also on the potential for improvement.

Performance evaluation

The Forest Reserves Project 111 is an example of best practices for steam injection operations. The project had cyclic steam injection in 1965, a pilot flood in 1967, and expansion pattern floods in 1968, 1971, and 1977.6

The project's peak production was 2,600 bo/d in 1979. By June 1995, it had recovered 12.8 million bbl, or nearly 70% of the original oil in place, with 57 million bbl of steam injected.6 By 1997 production fell to 400 bo/d with a 90% water cut, and the operator converted the project from a mature steamflood project into a WASP to stop the oil production decline.

Current production is about 100 bo/d.

Performance indicators for determining when to convert include levelling off of gross fluid, a straight-line oil production decline, and upward linear increase in water-oil ratio and slope of the average reservoir pressure curve.9

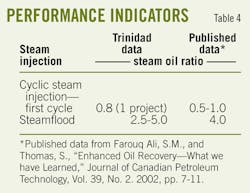

A performance evaluation for nine successful steamflood projects in Trinidad (Table 3) indicate that a steam-oil ratio of 2.0-5.0 to be an efficient production practice.6

For cyclic steam injection to produce 10% of the original oil in place, the accepted practice used up to six cycles, a 10,000 bbl/cycle steam slug size, a 2-week soak period, up to a 6-month production cycle, and a 1.0 steam-oil ratio.

Table 4 summarizes the injection-production ratio for heavy oil recovery by steam injection in Trinidad.

The future

Trinidad has the potential to embark on a steam injection program to increase its heavy oil production. With the existing facilities in place, and the experience of the high success rate of existing onshore projects makes steam injection attractive.

A 3D seismic project already planned across the major heavy oil fields will help determine reservoir continuity and fault block identification. Reservoir characterization and simulation studies also will aid in suitable well placement for injectors and producers.

The use of horizontal wells for cyclic steam injection with portable steam generators is also a possibility.

New processes such as steam-assisted gravity drainage (SAGD)12 also may have potential (Fig. 4), although Trinidad's complex geology and shale laminated reservoirs may affect adversely this method.13

Preliminary screening models indicate that SAGD requires a minimum 50-ft clean reservoir thickness without any shale layers.14 This thickness will provide the gravity drainage drive energy and the oil in place to support the cost of dual horizontal wells on 16 ft vertical spacing.

Another possible process is vapor extraction of oils using a solvent (Vapex), which is similar to SAGD but uses vapor instead of steam.15 16 The process involves the injection of vapor (such as ethane, propane, butane, or mixtures of these) at reservoir temperature and pressure to reduce oil viscosity. The diluted oil drains along the heavy oil-diluted oil interface by gravity to the lower well from which pumps produced the oil to surface (Fig. 4).13 15

This process is suitable for thin homogeneous formations where thermal processes are inefficient. The solvent cost, however, is high ($100/bbl for propane).

Acknowledgments

The authors thank Vijay Ramlal of Petrotrin and Craig Boodoo of the Ministry of Energy and Energy Affairs for their assistance with supporting data and Clyde Abder of the University of The West Indies for his technical input on cyclic and continuous steam injection in Trinidad.

References

1. 2009 Petrotrin Exploration and Production Annual Report.

2. EOR-Heavy oil surveys, OGJ, Apr. 20, 1992, p. 19; Sept. 26, 1994, p. 51; Apr. 15, 1996, p. 39; Apr. 20, 1998, p. 49; Mar. 20, 2000, p. 39; Apr. 15, 2002, p. 43; Apr. 12, 2004, p. 45; Apr. 17, 2006, p. 37; Apr. 14, 2008, p. 45; Apr. 19, 2010, p. 36.

3. Kennan, L., and Pindell, J., "Middle Miocene orogeny in Trinidad: Record of Caribbean collision and template for younger deformation in Caribbean exploration—Planning for the future," GSTT 4th Geological Conference, Port of Spain, Trinidad, June 17-22, 2007.

4. Wach, G.D., and Archie, C., "Regional Distribution and Controls of Heavy Oil and Oil Sand in the Eastern Venezuelan and Trinidad Basins," Search and Discover Article No. 40285, Mar. 31, 2008, http://www.searchanddiscovery.net/documents/2008/08022wach02/images/wach.pdf.

5. Albewhite, K., and Higgins, G.E., "A Review of Trinidad West Indies Oil Development and the Accumulations at Soldado, Brighton Marine, Grande Ravine, Barrackpore-Penal and Guayaguayare," Fourth Caribbean Geological Conference, Port of Spain, Trinidad, Mar. 28-Apr. 12, 1965.

6. Ramkhalawan, C.D., Khan, J., and Bainey, K.R., "Thirty Years of Steamflooding: Reservoir Management and Operational Experiences, Paper No. SPE30772, SPE Annual Technical Conference and Exhibition, Dallas, Oct. 22-25, 1995.

7. Russell, A., "Reservoir Properties of Trinidad and Tobago Formations," GSTT Technical Seminar, San Fernando, Trinidad, 1988.

8. Taber, J.J., Martin, F.D., and Seright, R.S., "EOR Screening criteria Revisited—Part 1: Introduction to Screening Criteria and Enhanced recovery Field Projects," Paper No. SPE 35385. SPE Reservoir Engineering, August 1996, pp. 189-98.

9. Ramlal, V., and Sono, S.K., "Success of Water-Alternating-Steam-Process for Heavy Oil Recovery, Paper No. SPE 69905, SPE International Thermal Operations and Heavy Oil Symposium, Margarita Island, Venezuela, Mar. 12-14, 2001.

10. Bautista, L.S., and Friedmann, F., "Water-Alternating-Steam-Process (WASP) Alleviated Downdip Steam Migration in Cymric Field, Paper No. SPE/DOE 27794, Ninth Symposium of Improved Oil Recovery, Tulsa, Apr. 17-20, 1994.

11. Hong, K.C., and Stevens, C.E., "Water-Alternating-Steam-Process Improves Project Economics at West Coalinga Field," Paper No. SPE 21579, SPE Reservoir Engineering. February 1987, pp. 67-76.

12. Butler, R.M., Thermal Recovery of Oil and Bitumen. Englewood Cliffs, N.J.: Prentice Hall, 1991.

13. Batohie, G., and Dawe, R.A., "Modelling the VAPEX and SAGD side wall process with a wax heating experiment," Journal of Petroleum Science and Technology, in press, 2012.

14. Nilsen, C., McCash, K., and Kapila, M., "Tar-Sands Drilling-Waste Management: A Clean Solution," Paper No. SPE 112368. SPE/IADC Drilling Conference, Orlando, Mar. 4-6, 2008.

15. Das, S.K., "Vapex: An efficient process for the recovery of heavy oil and bitumen," Paper No. SPE 50941, SPE Journal, September 1998.

16. Roopa, I., and Dawe, R.A., "Vapex—Gravity Assisted Film Drainage for Heavy Oil Recovery," Journal of Petroleum Science and Technology, Vol. 25, No. 5, 2007, pp. 645-58.

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com