Editor’s note: The following is operational information extracted from written testimony submitted by Steve Marshall, president of BP Exploration (Alaska) Inc., to a Sept. 7 hearing on Prudhoe Bay oil pipeline corrosion held by the Subcommittee on Oversight and Investigations of the US House of Representatives Energy and Commerce Committee.

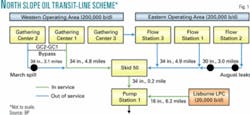

In March of 2006, BP Exploration (Alaska) Inc. (BPXA) discovered a leak along the GC-21 line in the Western Operating Area [of Prudhoe Bay oil field] (WOA). This is a 34-in. line that carries sales quality crude oil to a central gathering center (GC) for ultimate delivery into the Trans Alaska Pipeline System (TAPS) at Pump Station 1 (Fig. 1). The leak was approximately 5,000 bbl, the largest spill ever on the Alaskan North Slope.

Shortly thereafter, the US Department of Transportation (DOT) issued a Corrective Action Order (CAO) to BPXA ordering it to perform “smart-pig” tests along with other inspection methods along both the Western and Eastern Oil Transit Lines (OTLs). There were a number of complex technical issues to resolve before the tests could be conducted, including developing a solution for managing the solids generated during the pigging operation.

BPXA began pigging operations along the Lisburne OTL in June. In-line inspection (ILI) of the Lisburne OTL showed good results and affirmed our confidence that the lines where fit for service. BPXA began pigging operations along the Eastern OTL in early July. Analyses of these smart-pig inspections were received on Friday, Aug. 4, and indicated 16 significant anomalies at 12 different locations along a segment of the Eastern OTL.

BPXA began immediate physical and ultrasonic testing of these anomalies and verified the presence of additional corrosion. BPXA’s inspections also revealed insulation staining along a segment of the Eastern OTL.

With the knowledge of these results, BPXA immediately shut down production at Flow Station 2 (FS-2) as a precautionary measure, and BPXA technicians subsequently discovered a small leak after close visual inspection along the FS-2 to FS-1 pipeline segment.

The smart-pig results along the Eastern OTL were unexpected. Because the exact cause of the corrosion mechanism was unknown, BPXA was concerned over the condition of the Western OTL. Thus, BPXA took the prudent step on the morning of Aug. 6 of announcing our intent to systematically shut down both sides of the Prudhoe Bay field until existing inspection data could be further assessed and verified with follow-up inspections.

Some have questioned whether BPXA made a rash decision to shut down the field over a small leak. To me, as president of BPXA, the decision to shut down was a reaffirmation of BP’s values and was the responsible thing to do. We took this step to prevent a potential release from occurring.

In light of these incidents, many have alleged that BPXA’s inspection and maintenance program was inadequate. Given our almost 30-year performance history and our existing programs, we believed we had an effective corrosion-management program in place.

Clearly, recent events have shown that our program did not detect the type of pitting corrosion identified here. We are examining and analyzing this data closely to ensure that we apply this learning to improve our program.

Corrosion prevention

Corrosion is the natural degradation of a material like steel pipe that results from a reaction with its environment. While corrosion cannot be eliminated, it can be effectively managed through a combination of monitoring and mitigation treatments. The goal of corrosion-mitigation programs is to control corrosion rates to acceptable levels.

Corrosion rates are not static, however, and they can increase or decrease depending on fluid properties or changes in conditions that affect the efficacy of corrosion inhibitors. For that reason, locations that are prone to corrosion damage, or where damage has been identified, are inspected as often as every 3-6 months.

BPXA uses pigging, ultrasonic testing (UT), visual inspections, corrosion inhibitors, and other techniques as appropriate for each individual oil field’s characteristics. We employ a risk-based management program whereby resources/activities are concentrated in areas where corrosion is expected to occur.

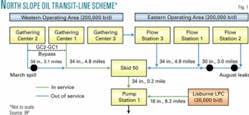

BPXA’s program was designed to control corrosion, extending the useful life of valuable North Slope infrastructure. The 2006 annual budget for BPXA’s corrosion monitoring and mitigation program is $74 million, an increase of 15% from 2005 and 80% from 2001. As [Fig. 2] demonstrates, corrosion management spend has increased significantly over the last 5 years despite the reduction in Prudhoe Bay production volumes.

Inhibition

A key element of the program is widespread continuous inhibitor injection. In short, the best way to address corrosion is to prevent it from happening in the first place.

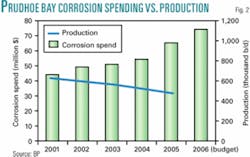

Our commitment to effectively managing corrosion on the North Slope is reflected in our corrosion inhibitor injection rates. [Fig. 3] is a diagram of the inhibitor concentrations and the corresponding corrosion rates achieved as measured by corrosion coupons.

We continuously monitor the effectiveness of the inhibition programs with corrosion coupons and electrical resistance (ER) probes. The ER probes take readings every 4 hr of the corrosion potential of the fluids and allow us to make adjustments to corrosion inhibitor injection rates on a weekly basis.

We have not been satisfied with simply maintaining the status quo. We conduct an ongoing and very active inhibitor research program.

Monitoring and inspections

BP’s North Slope pipeline monitoring and inspection program incorporates combinations of ultrasonic, radiographic, magnetic flux, guided wave, and electromagnetic inspection techniques. Ultrasonic and radiographic testing methods are used as indicators to trigger further action and are sound for pipelines that are accessible above-ground.

BPXA’s overall annual inspection program consists of conducting inspections at about 100,000 locations on pipelines in Prudhoe Bay. Of these inspections, approximately 60,000 are for internal corrosion inspection, and approximately 40,000 are for external corrosion inspection.

BPXA runs approximately 370 maintenance pigs/year on the North Slope. In addition, we utilize coupon monitoring, smart pigging, leak-detection systems, and surveillance by personnel to provide integrity assurance and maintain safe operations.

Lines are pigged in Prudhoe Bay either because of mechanical issues or because corrosion monitoring suggests it. The frequency of pigging is specific to each pipeline and varies significantly across the North Slope and the industry. For example, the Northstar oil pipeline is pigged every 2 weeks to prevent paraffin build-up.

Another technology is UT, which involves the use of a high-frequency sound wave to produce a precise measurement of the thickness of a material. Our UT inspections are not simply one reading at one location on the pipe. Rather, they are an inspection of the full circumference of the pipe over a 1-ft length. So when we count one UT inspection, it is really hundreds of individual readings at one location. The technology is a proven diagnostic tool routinely used for corrosion monitoring.

We also use corrosion coupons throughout our operations in order to obtain additional information about any corrosive conditions that might exist in our systems that escaped other inhibition and monitoring programs. The majority of our coupons are read on a 3-4 month basis.

Important components of pipeline inspections also include regular visual inspections and the use of forward-looking infrared (FLIR) devices. FLIR technology is used to spot heat signatures of crude oil and is especially useful during winter months.

Mitigation of corrosion

In the design of pipelines, many corrosion-mitigation methods are considered. The selection of material from which to manufacture pipe, such as corrosion-resistant alloys like stainless or low-carbon steel, is one consideration. Another option is the use of various coatings and linings that provide pipelines protection against corrosive agents.

Technology used to protect metal structures from corrosion includes cathodic protection, a technique that is usually used in buried pipelines and takes advantage of electrochemical properties that reduce a metal structure’s corrosion potential.

Mitigation also involves the application of corrosion inhibitors and biocides in conjunction with preventative maintenance such as pigging and physical repair of external damage.

External corrosion is mitigated by removal of the source for the water, drying, cleaning and buffing of the damage area, and application of new insulation and/or coatings. If external corrosion limits the integrity of the pipeline then repair techniques are used such as sleeves, clock springs, clamps, and composite wraps.

What happened?

If the programs are so good, what happened?

The recent leaks were on the OTLs, which are the last step in the process before TAPS. By this point, the major corrosion battles have already been fought.

General corrosion and pitting in the OTLs were monitored by corrosion coupons on a quarterly basis and have consistently shown very low corrosive conditions in these lines, always below the BP-targeted wall thickness loss of less than .002 in./year.

In spite of their low corrosivity, the OTLs were included in our ongoing UT monitoring program. Monitoring results were confirmed annually and have consistently revealed corrosion to be under control on these lines.

It has been frequently reported that BPXA didn’t perform ILIs on these lines and that if we had this problem would have been prevented. In fact, the March 2006 pipeline failure occurred on the WOA line, which had been pigged in both 1990 and 1998. These inspections did detect some corrosion (in the range of 20-50% in some locations). The most severe known damage locations were inspected in following years and did not exhibit further growth. Neither the ILIs nor the follow-up inspections identified the corrosion problem that led to the March spill.

The first indication of a growth in corrosion came from our corrosion-monitoring program in the facilities upstream of the WOA OTLs. An increase in facility corrosion upstream of the WOA OTLs, while not alarming, caused us to perform additional UT inspections of the OTLs. The results of these inspections led us to schedule another ILI of the WOA OTL for mid-2006. Unfortunately, the March release occurred before that pig run was conducted.

It has been misreported that the OTLs have widespread corrosion. In fact, no evidence of general corrosion (i.e., wall loss throughout the pipe) along the OTLs has been found. If there was, it would have been quickly detected by our monitoring programs. Instead, the OTLs have widely spaced, mostly isolated dime-sized pits about 5-10 ft apart. The corrosion is more serious on the upstream segments of these lines, which have the lowest flow velocities.

Why wasn’t the pitting corrosion detected by BP’s monitoring program? BP had an active inspection program for these lines, but the isolated pits were too widely spaced to be detected by that program. For example, there was an inspection site adjacent to the site where a leak occurred. The inspection did not detect any corrosion-just a few feet away from a pit.

We initially believed that the corrosion along the WOA had developed due to certain operational changes in the WOA and that the Eastern Operating Area (EOA) was not similarly affected. Our initial inspections of the EOA line appeared to confirm this.

However, these conclusions were premature and made before the latest inspections were completed. The inspection of the EOA OTL revealed that the pattern of corrosion damage is similar in both the EOA and WOA, although the precise corrosion mechanism remains under study.

Coffman report

In the last few days, mention has been made of the annual reports that have been submitted by an engineering firm, Coffman, which reviewed BPXA’s inspection and maintenance program on behalf of the State of Alaska and found several deficiencies in BPXA’s program. The implication is that if these deficiencies had been addressed then the recent pipeline incidents would have been prevented.

Previous Coffman reports have noted there were isolated pockets of accelerated corrosion in BPXA’s North Slope infrastructure. Notably, Coffman also stated those problem areas were discovered during the regular course of inspection. Excerpts from recent Coffman reports are shown below:

- The 2003 report states: “From a global perspective of oil and gas production, Greater Prudhoe Bay (GPB) and related facilities have an aggressively managed corrosion-control program. This suggests an adequate long-term commitment to preserving facilities for future production and sensitivity to environmental consequences.”

- The 2004 report credits BP with transparency and candor and for maintaining a corrosion program in which there is no “acceptable” risk. It said BP’s program “is effective and exceeds common industry practice” and that “Corrosion in most of the pipeline system has been reduced to a negligible level.”

When discussing internal corrosion on oil lines, the Coffman reports focus attention on the “production system” of well lines and flowlines, the three-phase lines that carry a mix of oil, water, and gas. These are the lines where corrosion is more of a known threat than in the transit lines that carry processed oil. Coffman does not specifically discuss the OTLs in any of its reports.

Thus, while there were areas in Coffman’s reports recommending additional inspection and maintenance activities, on balance they offered support for the efficacy of BPXA’s corrosion-management program.

Path forward

BPXA’s incident analysis is under way, but we have already taken steps to characterize the problem and assess the integrity of all the OTLs. This information has been submitted to the Office of Pipeline Safety (OPS), whose staff is currently reviewing it. We also have outside experts who are reviewing the data and who will provide independent opinions about its adequacy.

We have been working in cooperation with OPS to ensure the safety and integrity of these systems. We pledge to continue working in cooperation with DOT and other interested stakeholders to ensure that these lines, and all our pipeline operations on the North Slope, are operated to a high standard of operational excellence.

Now we must focus our attention on the future and what we will do to mitigate the risk of future leaks occurring in these OTLs. We have committed to undertake seven key actions:

First-Run an ILI tool in each of the Prudhoe Bay OTLs that are returned to service.

Second-Confirm through testing the exact corrosion mechanism that caused this problem, and modify our mitigation programs accordingly.

Third-Implement maintenance pigging in all OTLs.

Fourth-Include all BP-operated OTLs on the North Slope into DOT’s Pipeline Integrity Management Program. This will cover all 122 miles of BP OTLs in Alaska.

Fifth-Replace 16 miles of WOA/EOA OTLs, regardless of ILIs outcome, in order to ensure velocity rates are acceptable. The estimated cost of this is in excess of $150 million.

Sixth-The organizational structure has been changed with the addition of a technical director to provide independent assurance of our integrity-management efforts.

Seventh-Spending on Prudhoe Bay major maintenance will increase to $195 million in 2007, a nearly fourfold increase from 2004 spending levels.

In addition to these physical changes we remain committed to work collaboratively and proactively with the DOT and state regulators.

Business resumption-WOA

BPXA has conducted more than 4,876 UT tests of the WOA OTLs subsequent to the Aug. 6 announcement. These subsequent inspection results have not indicated any wall-thickness loss greater than 36%.

In addition, BPXA has begun a surveillance effort that includes daily overflights using infrared cameras, as well as the use of hand-held infrared cameras on the ground. The cameras can detect small leaks by sensing changes in pipeline surface temperatures. Two vehicles with spill-response equipment and carrying observers with infrared leak-detection equipment are patrolling the line 24 hr/day. They will be teamed with pipeline walkers who will visually inspect the line 10 times/day.

Ongoing UT inspections have slowed in recent days due to the detection of asbestos fibers in the mastic used to secure the pipeline insulation. Additional tests are being conducted to determine what (if any) additional protective measures need to be put in place to enable employees to continue to perform insulation removal.

Production had been reduced by 90,000 b/d due to a compressor malfunction in GC-2. Replacement of the compressor was completed on Sunday, Aug. 27, and production in the WOA has been restored to approximately 220,000 b/d.

Business resumption-EOA

Work [in the EOA] continues on removal of insulation from pipe; line inspections and testing are under way. We are averaging 200-300 inspections/day.

About 160 workers are dedicated to this inspection effort. We are currently inspecting the 34-in. segment that runs from FS-1 to Skid 50. If the inspection results show that the line has integrity, we will request permission to restart that line from the DOT. We are currently working through a process with DOT to make that request once we can provide assurance that the line can be safely restarted and pigged. This will allow resumption of partial production from FS 1 and FS 3.

After restart, these line segments will need to be inspected with a smart pig to meet requirements imposed by the DOT. If inspection results indicate that the remaining EOA OTLs are not fit for service, then bypass options will be completed as soon as practicable.

Regarding the leak along the FS-2 transit line, the estimated 23 bbl of oil spilled has been cleaned up. The line currently holds about 13,000 bbl of crude. Metal sleeves have been installed on those sections of the transit line with severe corrosion. BPXA has submitted a plan to the DOT for deoiling this segment of line.

Concurrent with our inspection activities, bypass options are being pursued to restore as much production as possible in an environmentally safe manner. The focus is largely on the EOA and includes new options to divert production from each of the existing FS’s to Skid 50.

The production from FS-2 is being engineered to route to the Endicott production line through new piping.

The production from FS-1 is being engineered to route to the Endicott production line through new piping.

The production from FS-3 is being engineered to route through Drill Site 15 and then to a jumper into the Lisburne OTL. Work on these options will be completed by the end of October.

All of this work is taking place as BPXA prepares for ultimate replacement of the 16 miles of WOA/EOA OTLs. Sixteen miles of pipe has been ordered and is expected on the slope during the fourth quarter. We are hopeful that work can be completed during the winter construction season.

At this point, we do not have a schedule for restoring all or a portion of EOA production and can’t speculate on how long it’s going to take.

While many of the circumstances surrounding the incidents at Prudhoe Bay are known, there is much more that needs to be done to fully understand the corrosion mechanism we experienced. These results will be known in due course and will be shared in a fully transparent way. In the meantime, BPXA is committed to restoring full production to the EOA as soon as we are confident it can be done in a safe and environmentally responsible way.

New regulations

Historically, certain pipelines that operate at low stress were exempt from DOT oversight. This exemption applied to onshore pipelines such as OTLs on the Alaskan North Slope.

However, since the Mar. 2, 2006, spill from BP’s Western OTL (a low-stress system), DOT has proposed a rule to revise the low-stress exemption. Upon completion of its rulemaking process, it is likely that any low-stress pipeline that is in an environmental high-consequence area will become a regulated pipeline under DOT jurisdiction. These proposed regulatory changes are strongly supported by BP.

Abbreviations

BPXA - BP Exploration (Alaska) Inc.

CAO - Corrective action order

DOT - US Department of Transportation

EOA - Eastern Operating Area

ER - Electrical resistance

FLIR - Forward-looking infrared

FS - Flow station

GC - Gathering center

GPB - Greater Prudhoe Bay

ILI - In-line inspection

LPC - Lisburne Production Center

OPS - Office of Pipeline Safety

OTL - Oil transit line

UT - Ultrasonic testing

WOA - Western Operating Area