High-temp., insulated coating aids construction of Alberta bitumen pipeline

Demanding requirements of transporting dry bitumen in the 12-in. OD MacKay River Pipeline in Alberta led to development of an innovative coating system.

Material selection considered pipeline-operating requirements, operating temperatures of up to 130° C. (266° F.), environmental conditions, coating application processes in shop and field, reparability, and material costs.

An assessment of existing material testing procedures was performed and a number of standard qualification tests were modified to qualify coating materials. This qualification led to selection of a robust, cost-effective coating system.

While historical performance information is not yet available, long-term monitoring will likely validate the design and application of the insulated three-layer coating system used on the MacKay River Pipeline.

Continued development of the oilsands in the Fort McMurray area of Alberta led to a need for the pipeline, which moves bitumen production from the MacKay River area with little or no dilution (dry bitumen).

To flow without diluent, the bitumen must be heated, and heat must be retained by use of a continuous layer of insulation to ensure viscosity remains low. The high operating temperature and the environment through which the pipeline passes were major challenges for design and construction.

This article focuses on design, selection criteria, and testing of the coating system and discusses the important aspects of construction.

Moving heavy oil

The 35 km (22-mile) MacKay River Pipeline moves dry bitumen from Petro-Canada's MacKay River production facility to Enbridge Pipelines Inc.'s Athabasca terminal. There, the bitumen is blended and transported via the Athabasca pipeline to Hardisty, Alta.

Design capacity of the MacKay River Pipeline is 7,000 cu m/day (44,000 b/d).

Environmental and operating conditions of the pipeline posed substantial challenges for selection of a coating system.

An operating temperature of 120° C., with the possibility of short excursions up to 130° C. and a design life of 30 years substantially limited the range of feasible coating materials.

From an operational standpoint, it was necessary to design the coating system so that sufficient heat would be retained to enable the pipeline to be shutdown for 2 days and subsequently restarted while carrying an unblended product.

The right-of-way, consisting of segments of clay and wet (muskeg) terrain, imposed further design constraints upon the coating system.

Coating material testing began in October 2000. Pipe coating began in July 2001. Construction began in September 2001 and was completed by mid October 2001.

Pipeline operation began in December 2002.

Coating selection

Operational requirements and the environment were key influences on the final design of the coating system.

Thermal insulation was necessary to meet the heat-retention requirement needed to maintain the pumpability of dry bitumen even after a 2-day shutdown.

Polyurethane foam's relatively low mechanical strength made an external jacket essential. The jacket had to be robust and water-resistant to withstand the demands of the environment, consisting of clay soil, muskeg, and directional drill sections.

In addition, the possibility of a failure of the shop-applied coating or the field-applied joint coating drove the requirement that the anticorrosion barrier be suited to immersion service at elevated temperatures. All factors led to selection of an insulated three-layer coating system.

Historically, there have been similar insulated three-layer coating systems used around the world to transport fuel oils, sulfur, and sour gas. In Europe, district heating systems using an insulated three-layer coating system are quite common.

Insulated coating systems are also available for onshore and subsea pipeline applications. The operating temperatures of most insulated pipelines in North America are less than 110° C.

There were relatively few options for the anticorrosion layer, given that it must be able to withstand immersion conditions up to 130° C.

Three-layer polyolefin coating systems, one of the most robust coating systems available for immersion service, consist of fusion-bonded epoxy (FBE) primer, adhesive, and extruded polyolefin (Coating System B of CSA Z245.21-98).

Typically, these systems are limited to operating temperatures of less than 85° C. for polyethylene (PE) and 110° C. for polypropylene (PP), although some PP systems are rated considerably higher. PE tapes have been used for insulated pipelines operating up to 95° C.

Common high-temperature FBE coatings are frequently designed for use as a primer coat in multilayer coating systems; however, they are rated for high operating temperatures in dry conditions only. A standalone, high-temperature FBE coating, which had just become commercially available, was used as the anti-corrosion layer of choice for the MacKay River Pipeline.

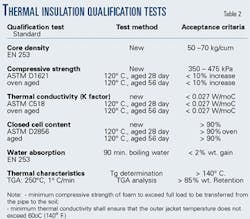

A spray-applied polyurethane foam based on a European district heating-approved product was selected as the insulation for the MacKay River Pipeline. This foam has a well-documented service history at high temperatures similar to project requirements. The foam system used on the European District Heating systems is mold-injected. Foam insulation is normally spray-applied in North America; thus some modification of the foam was necessary to speed up the curing process.

The foam thickness and thermal conductivity were selected to meet the operational requirement for an unblended shutdown window of 2 days.

This insulation thickness corresponded to an outer jacket temperature of 60° C.

Extruded PE is a relatively low-cost material with excellent properties including water resistance, toughness, impact resistance, and strength.

As a result, extruded PE has become an industry standard for protecting foam insulation.

Outer jackets consist of extruded PE with the option of a PE tape inner wrap between the foam insulation and the extruded PE.

The PE tape inner wrap tends to improve the impact and handling resistance of the outer jacket. The PE tape is either joined to the extruded PE outer jacket with an adhesive layer or by way of heat fusion.

A range of PE types is available for extrusion from low-density PE to high-density PE. The latter (HDPE) has the highest tensile strength and hardness of all extruded PE coatings and is the material of choice except for winter construction with temperatures dipping lower than –30° C., at which point the impact resistance and elongation at break decrease significantly.

At ambient temperatures of –40° C., HDPE may crack when subjected to moderate impacts or pipe movement. As such, low or medium-density PE is recommended for winter construction.1

Since the MacKay River Pipeline was scheduled for late summer or early fall construction, an outer jacket consisting of a PE tape inner wrap heat-fused to extruded HDPE was chosen.

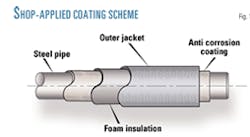

Shop-applied coating

Review of existing insulated three-layer coating systems and advice from a third-party consultant led to a base coating system being proposed for the shop and field-applied application.

Designers defined qualification and quality-assurance tests for each of the three individual layers as well as for the overall, composite system and, in cooperation with two coating applicators, selected specific coating materials.

The following system was proposed:

- Anti-corrosion coating: 350 mm (14 mil) nominal FBE.

- Insulation: 50 mm minimum polyurethane foam.

- Outer jacket: 2.5 mm (100 mil) minimum PE tape and extruded PE (directional drill: 3.8 mm).

Figs. 1 and 2 illustrate the shop-applied coating.

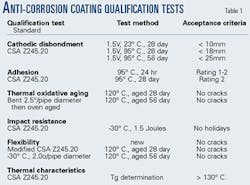

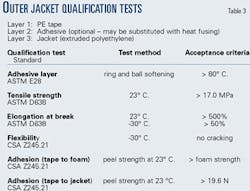

Following coating materials selection, the two applicators prepared and tested lab panels. Tables 1-3 show the qualification tests and corresponding acceptance criteria for the individual coating layers.

The coating systems proposed by each applicator were qualified on lab panels according to the requirements originally set out with select modifications.

The two applicators then coated test pipe during plant trials. Ring samples from the production pipe were subjected to qualification tests listed in Tables 1-3. In addition, the tests shown in Table 4 were performed on the composite coating system.

The FBE was qualified based on modified CSA Z245.20-98 cathodic disbondment and adhesion tests at temperatures up to 95° C., not at the design temperatures of 130° C. The only way to perform the 130° C. tests would be in a pressurized container (autoclave), and the results would be difficult to interpret considering the limited experience with this type of test. In addition, the realism of the test could be questionable.

In the case of an outer jacket failure, any moisture will be, in theory, driven out of the insulation covering the FBE at temperatures greater than 100° C., thereby validating the 95° C. tests. A glass transition temperature exceeding 130° C. indicated that the coating is suited to operation under intended service temperatures.

Technicians performed full-scale bend tests of up to 1.5°/pipe diameter length, the maximum allowed by CSA Z662-99, on production pipe coated by both applicators at temperatures lower than -25° C.

Examination of the field-bent pipe revealed that the outer jacket was free of cracking, the foam insulation had not been crushed, the PE tape to extruded PE layer was intact, and the foam insulation remained bonded to the FBE.

The foam experienced cracking during the bending of pipe coated by both applicators. Fit-for-service testing checked to indicate if such insulation cracks significantly increased the surface temperature.

Results revealed only a modest temperature increase of less than 5° C. at the surface with a 3-mm wide crack extending to the pipe surface when the pipe was heated to 115° C.

Despite these results, Enbridge decided not to perform field bending of insulated pipe. Pipe to be bent in the field was delivered with FBE coating only. It was then bent, coated with foam by means of sequential foam injection, and coated with a spray-applied polyurea coating.

Field joint coating

Liquid epoxy (novalac epoxy resin type) and FBE powder were considered for the anti-corrosion layer on field joints. The liquid epoxy had a number of advantages over the FBE powder including a lower preheat temperature, a simpler application procedure, and a lower cost.

Polyurethane-foam insulation at the field joints may be installed by foam injection or by use of pre-cut half shells. Cutting of foam half shells to fit each joint requires considerable time and manpower. More significantly, foam shells leave gaps in the insulation layer.

Besides increasing sleeve temperature during operation, such gaps allow a direct path for water to reach the anti-corrosion layer in the case of a field joint failure.

Foam injection involves injecting a polyurethane foam into a mold mounted over the girth weld. Following injection, the foam expands to fill the void completely.

This method was selected primarily because the foam bonds to the shop-applied foam to form a complete seal.

The foam formulation chosen for field application is quite similar to the shop-applied version with comparable thermal conductivity and compressive strength.

Several heat-shrink sleeves were considered for application over the field-injected polyurethane foam. Initially, leak-testable (casing) sleeves used in European District Heating systems, a proven technology, were assessed.

Double-layer sleeves and conventional (wrap-around), single-layer sleeves were also considered.

Application of each type of sleeve, from various manufacturers, was demonstrated and the final decision was to use a single-layer sleeve. The material costs, installation times, and complexity were considerably higher for double-layer and leak testable sleeves. The single-layer sleeve performance was considered adequate, although increased attention to training and inspection was important during installation.

The final field-joint coating system consisted of the following:

- Anti-corrosion coating: 500 mm minimum liquid epoxy.

- Insulation: 50 mm minimum polyurethane foam injected into molds.

- Outer jacket: heat-shrink sleeve (directional drill: edge protector sleeve required on leading edge).

Coating qualification, process

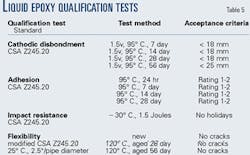

The manufacturer applied liquid epoxy to lab panels, and an approved third-party lab performed the tests shown in Table 5.

The liquid epoxy met all acceptance criteria shown in Table 5 with the exception of the 2.5° flexibility requirements.

Considering that field-joint coatings are not bent in the field, levels of flexibility lower than those expected for the shop-applied coating were acceptable.

Formulation of the field-injected polyurethane foam was similar to the shop and spray-applied version, except that there was less catalyst, slowing the cure process.

The foam could be poured into the mold and flowed to the bottom before expanding to fill the cavity.

Spray-applied foams are quicker reacting in order to prevent the foam running off the pipe.

The field-injected insulation underwent qualification testing in the manufacturer's lab according to the shop-applied foam qualification-test requirements.

The heat-shrink sleeves were assessed based on the following criteria:

- Ease of installation.

- Time of installation.

- Effects of preheat on shop-applied coating.

- Visual assessment of sleeve (noting adhesive flow at edges and lack of air entrapment).

- Peel testing at overlap to PE and to polyurethane foam (cohesive bond failures over the PE and adhesive bond failures over the foam, exceeding foam strength, were acceptable modes of failure).

Acceptable modes of failure included a cohesive failure over the PE and the adhesive bond to foam exceeding foam strength.

The FBE was applied according to requirements of CSA Z245.20-98. Immediately before this application, the pipe surface was abrasive blasted to SSPC-SP10/ NACE No. 2, near-white metal blast cleaning, treated with a phosphoric acid wash, rinsed, dried, and heated with a combination of induction coils and a propane-fired oven.

Following FBE application, it was quenched and inspected for holidays (coating damage or defects), which were repaired with the approved field-joint liquid epoxy.

The pipe was then temporarily stockpiled in the yard.

Before application of the foam insulation and the outer jacket, the FBE was again holiday tested for any discontinuities. Pipes with defects were set aside and repaired. Pipe free of holidays was cleaned of any foreign matter that would interrupt adhesion of the foam to the FBE.

The pipe was preheated with an induction coil and the coating flame-oxidized to ensure adhesion of foam to FBE.

Next, the polyurethane foam insulation was sprayed onto the pipe. As it cured, it was wrapped with PE tape, and finally PE was extruded over the PE tape.

The bond between the PE tape and extruded PE was achieved by heat fusion. The pipe was quenched and the foam cutback area was holiday-inspected and repaired as necessary.

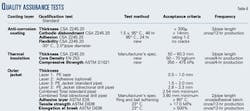

Technicians performed several quality-assurance tests throughout production; Table 6 describes the tests performed on each layer.

The pipe was coated in two steps. First, the pipe was coated with FBE and stockpiled. Subsequently it was coated with insulation and an outer jacket.

The desire to minimize the number of FBE repairs led to several precautionary measures in handling the pipe. Once the pipe was completely coated, pipe ends were covered with plastic bags to protect the exposed insulation from the elements and to maintain internal cleanliness of the pipe.

A loader with wide, padded forks to avoid damage to the coating (crushing) then transported the pipe to the stockpile. Finally, the pipe was stacked four tiers high on sawdust-filled bags.

Trucks transported the pipe from the applicator's facility to the site. A crane loaded pipe onto truck trailers, stacking it no more than four tiers high and placing short joints on the top two tiers.

During transport, the front end of each load was covered with a tarp to ensure that the end bags survived the journey.

Construction

Field application of a three-layer coating system is quite involved.

To ensure that field-joint coating proceeds smoothly, prospective contractors must understand the entire scope of work, the properties of all coating materials, and the overall job complexity during the bid stage.

Awarding of the contract should be followed by a prejob meeting at which the contractor demonstrates the field-joint application on a number of girth welds. This meeting makes certain that all installation details have been worked out and improves the chances of a successful job, from the perspective of both the contractor and the owner. Field training, provided by the manufacturers of each coating layer, is indispensable.

Pipeline construction on the MacKay River Pipeline began in mid September 2001 and was nearly completed by mid October. In field training at the beginning of construction, each worker involved in the field-coating process was trained and certified by the coating manufacturers. Only workers with certification were allowed to apply the field joint coating.

The steps in the field-joint coating process consist of:

- Preheating the girth weld with an induction heater or propane method to remove moisture.

- Abrasive blasting the girth weld area to SSPC-SP10/ NACE No. 2, near-white metal blast cleaning and verifying appropriate surface profile.

- Preheating the girth weld to an appropriate preheat temperature by means of an induction coil.

- Applying liquid epoxy and allowing to cure.

- Performing holiday detection and repair as necessary.

- Injecting foam and allowing to cure.

- Abrading the PE overlap.

- Preheating the PE overlap with propane torches.

- Applying the shrink sleeve according to manufacturer's instructions.

Welders were required to use pads to protect the FBE from damage caused by weld spatter. Such damage can be difficult to repair especially if it is next to the polyurethane foam.

Welders were encouraged to protect the polyurethane foam during preheating and welding.

Determining the length of the polyurethane foam cutback must consider the width of heating device used to preheat the girth weld area. If the exposed girth-weld area is shorter than the width of standard heating equipment, specially designed heating devices may have to be constructed or an alternate heating system used.

Induction coils and catalytic heaters offer a number of advantages over a propane torch.

These include elimination of damage (charring) to the polyurethane foam and FBE, prevention of contamination of the substrate before liquid-epoxy application, reduction of flash rusting, and assurance that the pipe preheat temperature is evenly distributed around the pipe circumference.

On the MacKay River Pipeline, the foam cutback was specified as 175 mm nominal, which did not provide enough space for standard induction coils or catalytic heaters. As such, the following procedure was used for field-coating application:

- Preheating the girth weld with propane torches.

- Abrasive blasting the girth-weld area to SSPC-SP10/ NACE No. 2, near-white metal blast cleaning.

- Reheating the girth weld with propane torches due to rapid cooling of the steel.

- Brush blasting the girth weld to remove contaminants and flash rusting caused by reheating.

- Brushing off the girth weld.

- Applying the liquid epoxy.

This procedure was less than ideal, considering that abrasive blasting and coating operation were never more than one joint apart.

Achieving reasonable liquid-epoxy cure times required that temperature of the steel to be high but not so high as to damage the coating or initiate release of harmful vapors.

Pipe adjacent the girth weld acted as massive heat sinks, cooling the girth-weld area and leading to extended epoxy cure times. In order to improve the process, entire welded sections of pipe were preheated by blowing hot air in one end.

Injection of foam into the molds proved relatively trouble free.

Once the liquid epoxy had cured and was holiday free, steel molds were mounted over the girth weld. Since the isocyanate in the foam reacts with water, the girth welds were wiped dry before the foam injections. The polyurethane foam was injected into the mold, the amount being controlled by either timing or counting the number of pump strokes.

The steel molds were treated with a silicone-based release agent. The amount of release agent used was minimized because any residue would adversely affect adhesion of the shrink sleeve to the PE overlap and to the polyurethane foam.

Before heat shrink-sleeve application, after the foam insulation had cooled, the mold was removed and the insulation inspected for defects before heat shrink-sleeve installation. The PE overlap was abraded to improve sleeve adhesion and to remove all traces of foam adhering to the PE.

The PE overlap area was preheated to the minimum preheat temperature recommended by the sleeve manufacturer. Heating of the polyurethane foam was minimized to avoid damage and to reduce off gassing.

Adequate and even preheating of the PE overlap area was critical to ensure that the hot-melt adhesive used on the sleeve was activated. The sleeve was installed with a minimum overlap of 75 mm.

Sufficient rolling during the sleeve application was required to ensure all entrapped gases were removed.

Drill sections of more than 500 m long were required for crossing major waterways and several roads. Edge protectors were applied to the leading edge of all shrink sleeves to lower the risk of sleeve damage.

In addition, the diameter of the drill bore was oversized to reduce the possibility of damage.

All directional drills were successful as the coating on the lead joints pulled beyond the exit was in good condition and resistance-to-ground measurements taken at each crossing revealed high resistance.

Valves and fabricated bends were coated in the shop, with the liquid epoxy approved for girth welds, through plural-component spray application. Aboveground portions of the valves were painted with an epoxy phenolic paint.

These items were coated in the field with polyurethane foam with a sequential injection molding process and subsequently coated with a spray-applied polyurea coating.

Repairs to the outer jacket and the heat-shrink sleeves depended upon the size of the defect. For all sizes of defects, the PE outer jacket was abraded before application of the repair material. Repairs smaller than 50 mm x 50 mm were effected with PE repair patches, ensuring a minimum overlap of 75 mm.

Heat-shrink sleeves were used to repair any larger defects.

Before lowering of the pipe in the ditch, the outer jacket was carefully inspected for damage and repaired as required.

Cathodic protection

Mainline and station piping will be protected with cathodic protection (CP) using impressed current; however, studies have shown that the PE outer jacket and insulation may limit the effectiveness of CP systems.

Not only is PE known to shield CP under certain conditions, but also large ohmic drops are experienced across polyurethane foam insulation. Regardless, the CP system is intended to provide protection in damaged areas where the CP current is not shielded. Where the CP current is shielded, the anti-corrosion layer is designed to protect the pipeline.

Qualified CP inspectors were selected to evaluate coating conditions at directional drill sites, install CP test facilities, and collect information for the final design and installation of the CP system.

Their duties included:

- Providing description of the topography in the area.

- Collection of soil resistivity data.

- Installation of CP test stations (including final pipe-to-soil checks after backfill).

- Recording the resistance-to-ground of pipe sections where directional drilling or slip-bore techniques were used to install pipe under roadways and rivers.

- Completion of preliminary current requirement testing at possible impressed current (rectifier, groundbed) sites for use in final design.

- Assessment of the effects of high-voltage AC interference.

The final CP design will cover the cathodic-protection system size and location, HVAC testing and mitigation, foreign crossing testing and mitigation, equipment installation, a static and energized survey, and a final report.

A comprehensive integrity-management plan is in place to ensure that safe operation and integrity of the pipeline is maintained from start up to deactivation of the line.

The plan includes monthly CP system maintenance inspections and annual CP surveys.

The pipeline will be internally inspected within 10 years of installation. Based on operation, the coating integrity, and the internal inspection results, an appropriate internal-inspection interval will be established and continually adjusted throughout the life of the pipeline.

Acknowledgments

Aissa Castro, formerly with Enbridge Pipelines Inc. and John Baron, Skystone Engineering Inc., were both extensively involved with coating system design and material selection for this project.

Reference

1. Alexander, M., and D'Agostino, C., "Performance of Pipeline Insulation Systems in Arctic Conditions," presented to the 12th International BHRA Conference, Nov. 4-6, 1997, Paris.

The authors

Cliff Winter, currently self-employed in Nanaimo, BC, was a pipeline-integrity engineer at Enbridge Pipelines Inc., Edmonton, in 2001-02, and before that employed by ABB Alstom Power Ltd. as mechanical systems engineer in Baden, Switzerland. He holds a BSc (1994) in mechanical engineering from the University of Alberta, Edmonton.

Rob Sillers ([email protected]) is a pipeline-integrity engineer for Enbridge Pipelines. He holds a BSc (2002) in industrial engineering from the University of Regina, Saskatchewan.

Allan Glowach is technical services manager for Garneau Inc., Nisku, Alta., and served as laboratory technician at Garneau for more than 11 years. He holds a BSc (1989) in chemistry from the University of Alberta, Edmonton.

Based on a presentation to the International Pipeline Conference 2002, Sept. 29-Oct. 3, 2002, Calgary.