New NGL-recovery process provides viable alternative

Two process technologies were evaluated: conventional turboexpander and the IPOR process.

The turboexpander process utilized in the study was a modern design (Fig. 2). Due to the richness of the feed gas, a propane refrigeration system with a low stage operating temperature of –35° F. at 3.4 psig was integrated into the process design to provide supplemental cooling. A portion of the ethane vapor stream from the overhead of the de-ethanizer column is consumed as fuel to achieve the residue-gas heating value specifications.

Fig. 3 illustrates the IPOR process used in the study. Feed gas enters the process unit at a compressor interstage pressure of about 365 psig. The propane refrigeration system operates at –10° F., much warmer than that required by the turboexpander process, and 16.7 psig. The minimum operating temperature of the de-ethanizer column is –42° F. and is of low-temperature carbon steel construction.

To achieve the residue-gas pipeline heating value specification, a portion of the ethane-rich noncondensable vapors from the de-ethanizer reflux drum is consumed as fuel, with the remainder mixing with the residue gas via the de-ethanizer overhead separator.

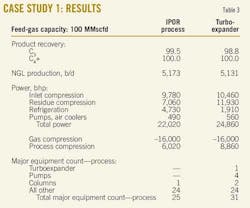

Tables 3 and 4 summarize the results of the study.

Compared with the turboexpander design, the IPOR process:

1. Achieves higher NGL recovery.

2. Requires about 32% less process compression power.

3. Requires about 20% less major equipment.

4. Requires less rotating equipment.

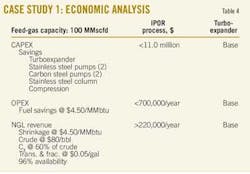

As a result, economics of the IPOR process are clearly superior to the turboexpander design, both from an OPEX and a CAPEX perspective (Table 4). Estimated capital cost of the IPOR process design was $11 million less than that of the turboexpander plant, the savings being the result of:

1. Less installed compression.

2. No turboexpander.

3. No light hydrocarbon/cryogenic pumps.

4. No stainless steel demethanizer column.

5. Less alloy material.

From an operating cost perspective, the IPOR process was estimated to consume about $700,000/year less in utilities, the savings resulting from lower compression power requirements, and hence fuel gas consumption.

Displaying 4/6

View Article as Single page