Medgaz pipeline promises energy security for Iberian Peninsula

The proposed Medgaz ultradeepwater natural gas pipeline linking Algeria and Spain, when complete, will transport up to 16 billion cu m/year (about 1.5 bcfd) gas to the Iberian and European energy markets. When commissioned in 2008, the pipeline will be able to meet gas demand in the Iberian market (Spain and Portugal), which recently has shown compound growth of 17%/year.

Extensive technical studies conducted by Medgaz have validated the proposed deepwater pipeline design and the associated offshore route, which will traverse the Mediterranean Sea at water depths of more than 2,000 m. These studies indicate that the proposed Medgaz pipeline will be the most economic solution for enhancing and ensuring energy security for the Iberian Peninsula.

This article details the design, operation, and environmental considerations that govern the project development strategy.

Iberian gas consumption, supply costs

Iberia’s fast-growing energy market poses challenges to the existing infrastructure. Spanish gas consumption grew from 21.4 billion cu m (bcm) in 2002 to 28.3 bcm in 2004. In 2011, demand will exceed 44 bcm.

Manufacturing growth and the need to switch to Kyoto Protocol-friendly energy are fueling the increased gas demand; system capacity, however, has barely managed to keep pace with the demand growth.

Several gas and power infrastructure projects are under way, but current peak-capacity shortages will stretch to 2010. Delays in increasing infrastructure capacity will harm development of the Iberian energy market in the short-to-medium term along with the growth potential of the economy.

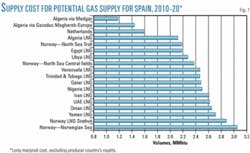

Independent energy consultants Observatoire Méditerranéen de l’Energie (OME) and Wood Mackenzie have studied the long-term marginal cost (excluding producing country’s royalty) for potential gas supply to Spain. The studies indicate clearly the economic benefits of the proposed Medgaz gas pipeline as the lowest-cost supply option for Spain (Fig. 1).

The project

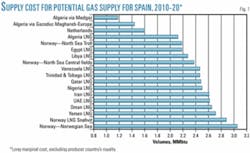

The Medgaz project was initiated by the Spanish energy company Cepsa and the state-owned Algerian energy company Sonatrach during 2001. Fig. 2 shows the current partnership structure of the project; Fig. 3 shows a schematic of the pipeline route.

The pipeline will be able to transport 16 bcm/year via two, 24-in. OD subsea pipelines planned for construction in two phases.

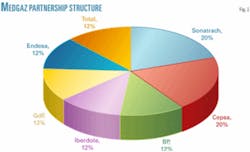

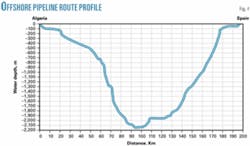

The two offshore pipelines will directly connect the Algerian gas fields and Spanish gas network across the Mediterranean (Alboran Sea) at a maximum depth of 2,155 m and an approximate length of 200 km (Fig. 4). The proposed route is characterized by gradual continental slopes on either side of the Alboran Sea. Quaternary clay soil occurs for the major part of the route, and sea-bed conditions are stable.

Two onshore terminals at either end of the pipeline will oversee transportation and delivery of gas from the Beni Saf compressor station, near Sidi Djelloul in Algeria, and the offshore pipeline receiving terminal near Almería, Spain.

Phase 1 will consist of construction of the east offshore pipeline and the short onshore sections for the second west pipeline, the compressor station at Beni Saf, and the receiving terminal at Almería, with a capacity 8 bcm/year.

Phase 2 will see construction of the west pipeline, which will bring total capacity to the 16 bcm/year.

Onshore connecting pipelines (to be constructed by others) include an Algerian section (550 km) and a Spanish section (285 km).

The pipeline’s design pressure is 220 barg. The maximum temperature is 60˚ C., the minimum 0˚ C. Design code is DnV OS F101. The offshore pipeline is 24-in. OD API Grade X-70, SAWL-485 I DUF. Pipe WT is 0.9 to 1.2 in. The heaviest wall pipe is to be deployed in the deepest part of the sea crossing.

Marine surveys

Several marine surveys performed during 2002-04 included:

Geological inspections of the proposed route.

• Environmental survey of marine flora and fauna on the offshore and onshore sections on the Algerian and Spanish sides.

• Geophysical investigations near the coasts at 25-m depth isobathe.

• Onshore inspections of the shore approaches in Algeria and Spain.

• A high-resolution seismic survey of the route for better evaluation of the geological risks.

• Bathymetry, environmental, visual, and magnetic surveys.

Route selection

The information provided by these surveys led to the selection of the definitive pipeline route to meet the following objectives:

• Minimization of environmental impact.

• Protection of marine flora and fauna on the offshore and onshore sections on the Algerian and Spanish sides.

• Avoidance of natural obstacles that exist along the route.

• Low geological and geotechnical risks.

• Minimal number of cable crossings.

• Ensuring the feasibility to employ both S-lay and J-lay construction method.

• Minimization of “free-span” risks.

Route characteristics

The length of the offshore route is 198.3 km, at a maximum water depth 2,155 m (49% deeper than 1,000 m). There are 19 curvature points and 5 places where the line will cross telecommunications cables (all at water depths greater than 1,000 m).

There is one geological fault crossing, the Yusuf fault, along with a critical zone from KP71 to KP77 (the Habibas escarpment) where the slopes are significant. More than 95% of the route has slopes of less than 4°.

Geotechnical investigations

During 2002, the Spanish government’s Consejo Superior de Investigaciones Científicas (CSIC), Barcelona, performed a comprehensive study of the geomorphology and seismic risks of the proposed offshore route that helped to focus the critical zones of the route for subsequent detailed study and geotechnical investigations.

Soil sampling and in situ tests were part of an in-depth geotechnical investigation carried out in 2003 at more than 130 locations along pipeline route. The work program included:

• Piston-corer sampling.

• Cone-penetration tests (CPT).

• Seismic CPTs.

• T-bar test.

• Water temperature and laboratory-chemical assay.

• Geotechnical laboratory tests including shear cyclic loading and carbon dating.

Geohazards

Based on the results of various surveys conducted by Medgaz and other subsequent technical studies, the proposed pipeline route will benefit from:

• The absence of significant geological and seismic risks.

• Ideal seabed conditions for pipelay and long-term operation of the pipeline.

• Few steep slopes. The steepest slopes encountered, at the Habibas escarpment, will not affect pipeline stability and long-term operation.

• The critical slopes of the route are stable for seismotectonic events with return periods of 475 years.

• The design of the pipeline is extremely robust for safe operation in conceivable earthquake conditions.

Environmental challenges

To minimize the environmental problems during construction, shore-approach sections of the second 24-in. pipeline will be built during Phase 1 construction of the first pipeline. Thus, when the second offshore pipeline is constructed, there will be no significant onshore construction activity in Algeria and Spain.

The width of the offshore corridor is minimized, while allowing sufficient space for the installation of the future second line. The work schedule will avoid significant construction installation activities close to the coastal zones during the peak tourism periods of the summer months.

Dredging and rock-dumping will be minimized to reduce the disturbance of sea bed flora and fauna.

Compressor station design

The Beni Saf compressor station’s inlet pressure will be 45 barg; the outlet pressure will be a maximum 200 barg.

Capacity for the Phase 1 operation of a single offshore pipeline will be 8 bcm/year. There will be three compressors in service, two low pressure and one high pressure.

Capacity for Phase 2 operation of the second offshore pipeline will be 16 bcm/year. This will include five compressors in service, three low pressure and two high pressure.

Receiving terminal design

The offshore pipeline receiving terminal’s arrival pressure will be 82 barg, and the arrival temperature will be a minimum of 0˚ C. The terminal will feature gas heaters for start-up operations, metering packages, pig receivers, and necessary safety and control valves. The Spanish pipeline entry pressure will be 80 barg.

Onshore environmental design

The Medgaz project has applied proven environmental principles for the design of the terminals. Some of the design features that will minimize environmental impact include:

• Specification of dry, low-emission turbines for compressor drives.

• Selection of the Beni Saf station’s compressor configuration for optimum fuel consumption at projected gas transportation rates.

• Use of air for actuation of the station’s valves.

• Use of flaring (instead of venting) during planned depressurization of either terminal.

Fig. 5 shows the current project schedule.

Energy security

The pipeline route is based on exhaustive studies that resulted in minimized project technical risks. The Medgaz project will use the latest proven deepwater-pipeline construction technologies to ensure minimum construction costs.

In-depth baseline studies and proven environmental principles will ensure environmentally friendly project implementation. In addition, the Medgaz project will contribute significantly towards the implementation of sustainable integrated energy plan for the Iberian peninsula.

That includes:

• Enhanced energy supply security for Spain and Europe.

• The most economic method of gas supply to the Iberian Peninsula.

• Promotion of competition in the Spanish and southern European energy markets.

The project has been approved as a “Quick Start” priority project under the European Union’s TEN-E program (Decision 1229/2003/CE).

On Jan. 12, 2005, the Spanish government advised that Priority Rating “A” will be accorded the Medgaz project, ensuring implementation will go forward to enable first gas delivery in 2009. ✦

Acknowledgment

The author thanks the companies that have so far participated in the Medgaz project for their technical contributions.

The author

Jay Chaudhuri ([email protected]) is project manager for Medgaz SA, Madrid, which will construct and operate the new gas pipeline linking Algeria and Spain. Chaudhuri has 24 years of oil and gas industry asset development and deepwater project experience. Chaudhuri previously was development manager for London & Scottish Marine Oil Co.’s (LASMO) Algerian asset portfolio during 1997-2001. Prior to that he worked as an engineer on various offshore projects. He holds a degree in naval architecture from Indian Institute of Technology, Kharagpur, India, and an MSc degree from Strathclyde University, Glasgow. Chaudhuri is a chartered engineer, amember of SPE, and a member of the Royal Institution of Naval Architects.

Based on a presentation to Gastech 2005, Mar. 14-17, 2005, Bilbao, Spain.