SPECIAL REPORT: US gas carriers’ 2005 net incomes climb; construction costs plummet

US natural gas pipeline operators continued to see their net profits grow in 2005, the nearly $3.9 billion earned marking an increase of almost 8%, following more than 10% growth in 2004.

Operators also continued to invest in capacity expansion, with formal construction plans brought before the US Federal Energy Regulatory Commission for new or expanded pipeline and compression nearly on par with the high levels seen the prior year, despite the tripling of the number of plans filed in the previous 12-month period ending June 30, 2005 (OGJ, Sept. 12, 2005, p. 50).

The balance of this mix of proposed construction, however, moved toward increased compression, with the number of new pipeline projects proposed declining. Total planned expenditure on additional compression more than tripled, according to the FERC filings, even as incremental ($/hp) costs decreased. Filings saw 11 of 43 plans for new (as opposed to additional) compression of more than 18,000 hp, with 5 of these for more than 30,000 hp.

Annual reports to FERC by US oil pipeline companies for the calendar year ending Dec. 31, 2005, showed declines in both earnings and revenues. The previous year’s sharp decline in carrier property, however, reached a plateau, with the amount of property change activity falling by nearly 36% from the unprecedented levels seen in 2004, indicating a potential pause in recent industry consolidation.

Incremental ($/mile) pipeline construction costs fell precipitously, despite material costs remaining high. Material costs also eased, but far steeper drops in all other cost items saw material costs supplant both labor and miscellaneous costs to become the single most expensive per-mile item. Actual costs were more than 14% below projected costs for the 12 months ending June 30, 2006.

US pipeline data

At the end of this article, two large tables (links to download PDFs of these tables are at the end of the article) offer a variety of data for US oil and gas pipeline companies: revenue, income, volumes transported, miles operated, and investments in physical plants. These data are gathered from annual reports filed with FERC by regulated oil and natural gas pipeline companies for the previous calendar year.

Data are also gathered from periodic filings with FERC by those regulated natural gas pipeline companies seeking FERC approval to expand capacity. OGJ keeps a record of these filings for each 12-month period ending June 30.

Combined, these data enable an analysis of the US regulated interstate pipeline system.

- Annual reports. Companies that, in FERC’s determination, are involved in interstate movement of oil or natural gas for a fee are jurisdictional to FERC, must apply to FERC for approval of transportation rates, and therefore must file a FERC annual report: Form 2 or 2A, respectively, for major or nonmajor natural gas pipelines; Form 6 for oil (crude or product) pipelines.

The distinction between “major” and “nonmajor” is defined by FERC and appears as a note at the end of the table listing all FERC-regulated natural gas pipeline companies for 2005 at the end of this article (p. 62).

The deadline to file these reports each year is Apr. 1. For a variety of reasons, a number of companies miss that deadline and apply for extensions but eventually file an annual report. That deadline and the numerous delayed filings explain why publication of this OGJ report on pipeline economics occurs in the third quarter of each year. Earlier publication would exclude many companies’ information.

- Periodic reports. When a FERC-regulated natural gas pipeline company wants to modify its system, it must apply for a “certificate of public convenience and necessity.” This filing must explain in detail the planned construction, justify it, and--except in certain instances-specify what the company estimates construction will cost.

Not all applications are approved. Not all that are approved are built. But, assuming a company receives its certificate and builds its facilities, it must-again, with some exceptions-report back to FERC how its original cost estimates compared with what it actually spent.

OGJ spends the year July 1 to June 30 monitoring these filings, collecting them, and analyzing their numbers.

For 2001, OGJ began reporting what natural gas companies spent during the year on operations and maintenance (OGJ, Sept. 16, 2002, p. 52).

The table on natural gas companies has tracked how the US gas transmission industry has changed under reduced regulation.

OGJ’s exclusive, annual Pipeline Economics Report began tracking volumes of gas transported for a fee by major interstate pipelines for 1987 (OGJ, Nov. 28, 1988, p. 33) as pipelines moved gradually after 1984 from owning the gas they moved to mostly providing transportation services.

Volumes of natural gas sold by pipelines have been steadily declining, so that, beginning with 2001 data in the 2002 report, the table only lists volumes transported for others.

The company tables have also reflected the recent asset consolidation and merger activity among companies in their efforts to improve transportation efficiencies and bottom lines.

Reporting changes

The number of companies required to file annual reports with FERC may change from year-to-year, with some companies becoming jurisdictional, others nonjurisdictional, and still others merging or being consolidated out of existence.

Such changes require that care be taken in comparing annual US petroleum and natural gas pipeline statistics.

Institution by FERC of the two-tiered (2 and 2A) classification system for natural gas pipeline companies after 1984 further complicated comparisons (OGJ, Nov. 25, 1985, p. 55).

Only major gas pipelines are required to file miles operated in a given year. The other companies may indicate miles operated but are not specifically required to do so.

For several years after 1984, many non-majors did not describe their systems. But filing descriptions of their systems has become standard, and most now provide miles operated.

Reports for 2005 show an increase in FERC-defined major gas pipeline companies: 71 companies of 112 filing for 2005, from 70 of 114 for 2004.

The FERC made an additional change to reporting requirements for 1995 for both crude oil and petroleum products pipelines.

Exempt from requirements to prepare and file a Form 6 were those pipelines with operating revenues at or less than $350,000 for each the 3 preceding calendar years.

These companies must now file only an “Annual Cost of Service Based Analysis Schedule,” which provides only total annual cost of service, actual operating revenues, and total throughput in both deliveries and barrel-miles.

In 1996 major natural gas pipeline companies were no longer required to report miles of gathering and storage systems separately from transmission.

Thus, total miles operated for gas pipelines consist almost entirely of transmission mileage. To continue to convey a 10-year trend, Table 1since 1995 has been adjusted to reflect only transmission mileage operated.

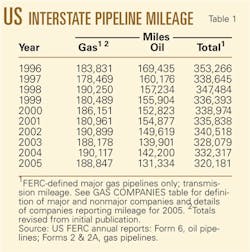

FERC-regulated natural gas and oil pipeline mileage decreased in 2005 after having increased in 2004 (Table 1). Final data show a decrease of more than 12,000 miles, or nearly 4%.

This decrease in majors-operated transmission pipeline mileage came largely on the back of a 7.77% decrease in oil mileage. The decrease in oil mileage occurred across all segments-gathering, as well as crude and products trunk lines-but was most pronounced in majors-operated gathering systems, which lost 1,389 miles (more than 9%).

Rankings; activity

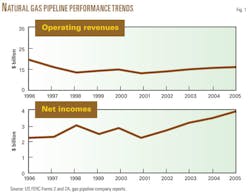

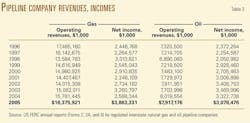

Major natural gas pipeline companies in 2005 saw another increase in operating revenues, up by more than $613 million or slightly more than 4% from 2004. The results were roughly similar when both major and nonmajor pipelines are considered, and in both cases shrank in comparison to the $685 million, nearly 5%, move seen for majors in 2004 from 2003.

This smaller jump in revenues, however, once again translated into the highest net incomes yet seen for either majors or all companies combined. Income for majors improved by more than 7%, or more than $254 million, with increases seen for all companies in 2005 of nearly 8%.

Additionally, income as a percent of revenues increased for the fifth straight year, reaching 23.1% in 2005.

For oil pipelines, on the other hand, both operating revenues and incomes fell. Revenues declined by roughly $102.4 million, or 1.3%, partially reversing the gains seen in 2004, while incomes fell more than $246 million or 7.4%, accelerating the 4.2% declines seen in 2004.

Once again, Burlington Resources Trading Inc. represented the bulk of these losses, with a 2005 net income of -$167.6 million.

Products deliveries for 2005 via pipeline fell 725.5 million bbl or nearly 11%, more than retracing the gains seen in 2004. Crude oil deliveries, in contrast, rose nearly 64 million bbl, nearly 1%. Throughput measured in million bbl-miles (bbl-mile: 1 bbl moving 1 mile) declined roughly 4.6%, by more than 167 billion bbl-miles, led by product throughput dropping by more than 134 billion bbl-miles, or 6.6%

OGJ uses the FERC annual report data to rank the top 10 pipeline companies in three categories (miles operated, trunkline traffic, and operating income) for oil-pipeline companies and three categories (miles operated, gas transported for others, and net income) for natural gas pipeline companies.

Positions in these rankings shift year to year, reflecting normal fluctuations in companies’ activities and fortunes. But also, because these companies comprise such a large portion of their respective groups, the listings provide snapshots of overall industry trends and events.

Company financial data for all companies, not just the majors in both types of pipeline service, provide a view of the ongoing condition of these industries (Fig. 1; Table 3).

For all natural gas pipeline companies, for example, net income as a portion of operating revenues rose in 2005 to 23.08%, after having risen in 2004 to 22.74% from 21.62% in 2003. As noted earlier, it was the fifth consecutive year of gains in this category, which stood at 15.59% in 2001

The percentage of income in operating revenues for oil pipelines hovered in the mid-20s for the first 5 years of the 1990s; for the last 10 years however, it pushed first into the 30s, reaching almost 39% in 2001, and was in the 40s for the past 3 years: 43% in 2002, 45% in 2003 and 41% in 2004.

Income as a percent of revenues retreated from these highs in 2005, returning to rough parity with 39% level seen in 2001.

Another measure of company performance and health is provided by a calculation of return on investment: net income as a portion of gas-plant investment. This has also improved over the past 4 years, moving from 3.6% in 2002, to 4.1% in 2003, 4.3% in 2004, and 4.6% in 2005, approaching the 4.7% levels seen in 1998.

For oil pipelines, net income as a portion of investment in carrier property in 2005 shrank to 10.4%, from 11.4% in 2004; reversing an upward trend begun in 1999, 8.6% vs. 6.8% in 1998, and reaching the lowest level seen since 9.35% in 2001.

Major and nonmajor natural gas pipelines in 2005 reported an industry gas-plant investment of nearly $84 billion, the highest level ever, up from more than $83 million in 2004, nearly $78 billion in 2003, $74.2 billion in 2002, almost $71 billion in 2001, $68 billion in 2000, nearly $66 billion in 1999, and more than $63 billion in 1998.

Investment in oil pipeline carrier property in 2005, by contrast, was relatively flat near $29.5 billion, following a nearly 8% drop between 2003 and 2004, leaving current investment levels at their lowest point since at least 1997.

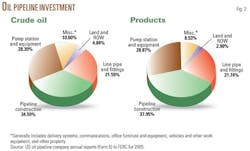

OGJ for several years has tracked carrier-property investment by five crude oil pipeline and five products pipeline companies chosen as representative in terms of physical systems and expenditures (Table 2). Starting in 2003, we added the base carrier-property investment to allow for comparisons among the anonymous companies.

The five crude oil pipeline companies in 2005 increased their overall investment in carrier property by nearly $108 million, or 3.6%; a similar grouping of companies decreased overall investment in carrier property by more than $74 million, or 2.4%, in 2004, after increasing overall investment in carrier property by more than 4.5% for 2003.

Miscellaneous investment (typically including delivery systems, communications, office furniture and equipment, vehicles and other work equipment, and other property) more than doubled as a percent (to 10.60% in 2005 from 5.05% in 2004) and passed land and ROW as a portion of overall investment.

The five products pipeline companies increased overall investment in carrier property in 2004 by a more modest $127 million, or 2.4%, following a $509 million (nearly 11%) increase in 2004 and a nearly 4% increase in 2003.

Comparisons of data in Table 2 with previous years’ must be done with caution: In 1998, a major crude oil pipeline company listed there merged with two other large pipeline companies. More transactions have followed, including the 2004 sale of significant assets by a major crude line, making comparisons with previous years’ data difficult.

Investment by the five product pipeline companies in 2005 was nearly $5.4 billion and continued a return to growth that started in 2003 when investment of more $4.7 billion was up from 2002’s $4.5 billion level.

Fig. 2 illustrates the investment split in the crude oil and products pipeline companies.

Construction stays strong

Applications to FERC by regulated interstate natural gas pipeline companies to modify certain systems must, except in certain instances, provide estimated costs of these modifications in varying degrees of details.

Tracking the mileage and compression horsepower applied for and the estimated costs can indicate levels of construction activity over 2-4 years. OGJ has been doing that since this report began nearly 50 years ago.

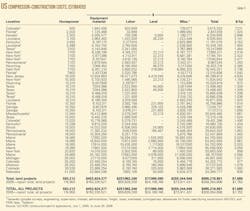

Tables 4 and 5 show companies’ estimates during the period July 1, 2005, to June 30, 2006, for what it will cost to construct a pipeline or install new or additional compression.

These tables cover a variety of locations, pipeline sizes, and compressor-horsepower ratings.

Not all projects that are proposed are approved. And not all projects that are approved are eventually built.

Applications filled in the 12 months ending June 30, 2006, leveled off, but remained strong following a marked rebound in the construction of future gas pipelines in 2005:

- More than 1,400 miles of pipeline were proposed for land construction, and 6.2 miles for offshore work. The land level is down from the more than 1,700 miles proposed in 2005, but still up significantly from 213 proposed miles in the 2004 report. Offshore proposals in 2005 totaled 92 miles, with no miles proposed offshore in 2004.

- New or additional compression proposed by the end of June 2006 more than tripled, reaching in excess of 583,000 hp from the nearly 175,000 hp envisioned by the pipelines in 2005 (Table 5) and eclipsing the more than 550,000 hp proposed for the same period in 2002. Only 76,000 hp was proposed in 2004.

With a 54% increase in the number of plans proposed for 2005-06, compared with a year earlier (which itself doubled the 2004-05 period) and the majority of these for new, as opposed to additional, compression, recognition of the need to add to the US gas transport infrastructure continues to be seen. Plans for new compression included 11 of more than 18,000 hp, with 5 of these for more than 30,000 hp.

Putting the continued rebound in US gas pipeline construction in some perspective, Table 4 lists 42 land-pipeline construction “spreads,” or mileage segments, and 1 marine project, compared with:

- 56 land and 4 marine projects (OGJ, Sept. 12, 2005, p. 50).

- 15 land and 0 marine projects (OGJ, Aug. 23, 2004, p. 60).

- 37 land and 3 marine projects (OGJ, Sept. 8, 2003, p. 60).

- 83 land and 3 marine projects (OGJ, Sept. 16, 2002, p. 52).

- 49 land and 2 marine projects (OGJ, Sept. 3, 2001, p. 66).

- 115 land and 6 marine projects (OGJ, Sept. 4, 2000, p. 68).

Further, of the 42 land pipeline projects applied for, 26 are for new pipeline as opposed to looping or replacement mileage. And of these 26, 7 are for pipeline of 50 miles or more in length, with 5 of these being for projects over 100 miles long (and 4 of the 5 of 42-in. OD).

For the 12 months ending June 30, 2006, the 42 land projects would cost more than $2.75 billion.

The number and nature of these filings, pending actual progress on the projects themselves, continue progress in addressing the infrastructural needs associated with anticipated US natural gas demand growth.

Projects’ cost projections indicate much about where companies believe unit construction costs ($/mile) are headed. It is telling that the number and scale of projects remain strong despite high costs.

For proposed US gas pipeline projects 2005-06, the average land cost was $1.95 million/mile; for 2004-05 the average land cost was $2.2 million/mile; for 2003-04 the average land cost was $1.7 million/mile; for 2002-03 the average land cost was $1.28 million/mile; and for the 2001-02 period, land pipeline cost estimates were more than $1.2 million/mile.

Offshore costs per mile slipped toward previous levels. Projects proposed in 2005-06 have a cost of $3.5 million/mile. No offshore projects were applied for in 2003-04. Those proposed in 2004-05 had a $6.07 million/mile cost, more than double the 2002-03 figure of $3 million/mile and roughly four times the 2001-02 rate of $1.5 million/mile.

Cost components

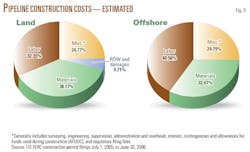

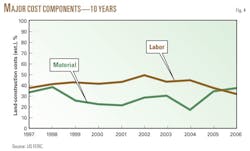

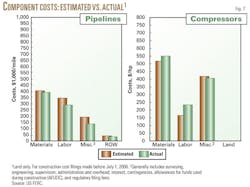

Variations over time in the four major categories of pipeline construction costs-material, labor, miscellaneous, and right-of-way (ROW)-can also suggest trends within each group.

Materials can include line pipe, pipe coating, and cathodic protection.

“Miscellaneous” costs generally cover surveying, engineering, supervision, contingencies, telecommunications equipment, freight, taxes, allowances for funds used during construction (AFUDC), administration and overheads, and regulatory filing fees.

ROW costs include obtaining rights-of-way and allowing for damages.

For the 42 land spreads filed for in 2004-05, cost-per-mile projections for the four categories all showed decreases, with labor and ROW showing particularly sharp declines, the latter for the second consecutive year:

- Material-$742,340/mile, down from $765,633/mile for 2004-05.

- Labor-$629,217/mile, down from $809,105/mile for 2004-05.

- Miscellaneous-$481,875/mile, down from $505,792/mile for 2004-05.

- ROW and damages-$99,608/mile, down from $135,358/mile for 2004-05 and $177,359/mile for 2003-04.

Table 4 lists proposed pipelines in order of increasing size (OD) and increasing lengths within each size.

The average cost-per-mile for the projects rarely shows clear-cut trends related to either length or geographic area. In general, however, the cost-per-mile within a given diameter suggests that the longer the pipeline, the lower the unit (per-mile) cost for construction. And lines built nearer populated areas tend to have higher unit costs.

Additionally, road, highway, river, or channel crossings, and marshy or rocky terrain each strongly affects pipeline construction costs.

Fig. 3, derived from Table 4, shows the major cost-component splits for land and offshore pipeline construction costs.

Material and labor for constructing land and offshore pipelines make up more than 70% of the cost. Material’s portion of estimated costs, however, has risen, moving to 38.17% in 2005 from 34.76 % in 2004 for land pipelines and to 32.67% from 14.04% for offshore pipelines.

Material costs passed labor as the single largest projected expense for land pipelines and are now second only to labor costs in projected expenses for offshore pipelines.

Fig. 4 plots a 10-year comparison of land-construction unit costs for the two major components, material, and labor.

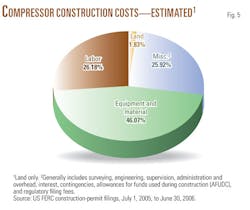

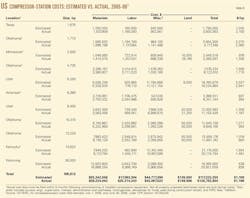

Fig. 5 shows the cost split for land compressor stations based on data in Table 5.

Table 6 lists 10 years of unit land-construction costs for natural gas pipeline with diameters ranging from 8 to 36 in. The table’s data consist of estimated costs filed under CP dockets with FERC, the same data shown in Tables 4 and 5.

Table 6 shows that the average cost per mile for any given diameter may fluctuate year to year as projects’ costs are affected by geographic location, terrain, population density, or other factors.

Completed projects’ costs

In most instances, a natural gas pipeline company must file with FERC what it has actually spent on an approved and built project. This filing must occur within 6 months after the pipeline’s successful hydrostatic testing or the compressor’s being put in service.

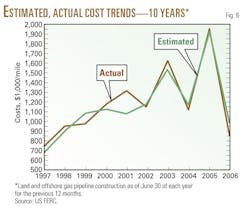

Fig. 6 shows 10 years of estimated vs. actual costs on cost-per-mile bases for project totals.

Tables 7 and 8 show such actual costs for pipeline and compressor projects reported to FERC during the 12 months ending June 30, 2006. Fig. 7, for the same period, depicts how total actual costs ($/mile) for each category compare with estimated costs.

Per-mile pipeline construction costs for completed projects fell precipitously, despite material costs remaining high. Material costs also eased, but far steeper falls in every other cost item saw material costs supplant both labor and miscellaneous costs to become the single most expensive per-mile item. Actual costs were more than 14% below projected costs for the 12 months ending June 30, 2006.

Some of these projects may have been proposed and even approved much earlier than the 1-year survey period. Others may have been filed for, approved, and built during the survey period.

If a project was reported in construction spreads in its initial filing, that’s how projects are broken out in Table 4. Completed projects’ cost data, however, are usually reported to FERC for an entire filing, usually but not always separating pipeline from compressor-station (or metering site) costs and lumping several diameters together.

The 12 months ending June 30 saw completed-project cost filings for 594 miles, a marked increase from the 341 miles reported for the year-earlier period, and nearly 106,000 hp of new or additional compression, continuing the decline reported the year before when 153,000 hp of new or additional compression were reported vs. 468,000 hp in 2004.

More than a third of the 2005-06 horsepower was from a single project.

Overall, actual land gas pipeline construction costs came in more than $140,000/mile below estimated costs, with a particularly large gap seen in miscellaneous costs. Table 8 shows the opposite trend between installed and estimated compression costs, with actual costs higher than estimated and the largest discrepancy seen in labor costs ($161/hp estimated vs. $239/hp actual).