Bakken greenfield refinery to sustain local growth

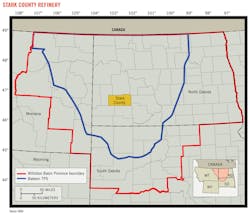

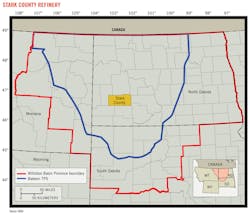

STARK COUNTY, N.D.—The Bakken Total Petroleum System (TPS) is estimated to contain 7.4 billion bbl of oil, 6.7 tcf of associated gas, and 0.53 billion bbl of natural gas liquids, according to a report released by the US Geological Survey (USGS). Updating its original 2008 assessment, the USGS used data from 4,000 additional wells drilled since its 2008 study. The study included Bakken and Three Forks formations in the Williston basin province of Montana, North Dakota, and South Dakota.

Approximately 450 million bbl of oil has been produced from the Bakken and Three Forks within the last 5 years. With this new supply, the region has seen new additions of infrastructure. On March 26, 2013, North Dakota Gov. Jack Dalrymple and MDU Resources President and CEO Dave Goodin broke ground on the first greenfield refinery to be constructed in the US since 1976.

Though small, MDU Resources and its partner Calumet Specialty Products LP see benefit for locally sourcing Bakken crude to provide diesel fuel for onsite use as well as other distillates for further refining. The refinery, or topping plant, will process 20,000 b/d of Bakken crude once completed in 2014. In addition to providing further access to infrastructure in North Dakota, the project will also provide longer-term, high-paying jobs for nearly 100 employees. At peak construction, the project will sustain more than 400 construction jobs.

Local growth

"This is a very good thing for the local economy," said Gaylon Baker, executive vice-president of the Stark County Development Corp. (SCDC). "Refineries supply long-term jobs that are capable of supporting an entire family," Baker added. Aside from jobs directly related to the refinery, Baker also said refinery projects often have a multiplier of four, which means a community can gain four jobs for every individual refinery job. "That means sustainability, which is the most important factor in economic development," Baker said.

In addition to living wages, the refinery's 30-year life cycle ensures future investment in Stark County. "People often want to know what becomes of things after the drilling activity ceases," said John Stumpf, vice-president of strategic planning, MDU Resources. "Community members have taken some comfort in knowing this project is providing long-term job opportunities."

Planning and execution

According to Baker, the process of permitting the new refinery began over a year ago. SCDC primarily helped the variety of partners coordinate the early stages of community involvement. "Our role was to make proper introductions and to network with the project partners," Baker said. "Early on, we identified ways to establish a good industrial area, and I think it has been a success."

"I would say the project has been a true partnership," Stumpf said. "Not only from a business perspective, but community and government relations were done professionally, and most of the feedback we received throughout the planning phase of this project was constructive," he said.

"We started an early process to introduce the project to community leaders and to the general public," Stumpf continued. A combination of townhall meetings and private meetings with community leaders and legislative groups helped MDU Resources and its partners engage the issues firsthand. "We cast a wide net and disclosed as much information as we could as early as possible," Stumpf said.

Environmental footprint

Typically, installations producing more than 100,000 tons/year of CO2 are considered major sources of greenhouse gas emissions. At 120,000 tons/year, the Dakota Prairie Refinery had to comply with EPA scrutiny based on the Clean Air Act. "Obtaining the air quality permit to construct was where most of the uncertainty resided," Strumpf said.

The process was simplified through the design phase. "We had to demonstrate that the technology we are deploying in the plant meets EPA criteria for the best available controls for minimizing the amount of overall emissions," Strumpf said.

Other environmental issues included the airshed. The topping plant will be 30 miles east of Theodore Roosevelt National Park. The company had to demonstrate that oxides of sulfur and nitrogen would be at a minimum —under 40 tons/year. This will be accomplished through the application of super-efficient burners. "We had to spec out the best combustion technology available on the market," Strumpf said. "But this falls into what is commercially available versus what is theoretically possible." Adopting new technology can sometimes add risk to a sizeable project and can introduce potential problems. "The greatest risk to air quality in refining is startups and shutdowns," Strumpf said. "If we're using tried and true technology that has proven to be efficient, we can lower our risks against unplanned shutdowns."

Overall, the regulatory path to the new refinery under construction was relatively smooth. "We felt the process worked the way it was designed to work," Strumpf said. Both the EPA and North Dakota Health Department, which was in charge of permitting this project, were constructive throughout the permitting stage, according Strumpf. "It wasn't easy, but it was very fair."

Supply and demand

Once online, the 20,000 b/d refinery will produce 40–50 tankers of diesel per day (7,000–8,000 b/d). While this will displace a portion of the fuel that is currently trucked or railed in, it will hardly put a dent in local demand, according to Strumpf, although the partnership formed to construct the project was founded in convenience and efficiency.

Calumet Specialty Product Partners came to Bismarck, ND, in December 2011. "They were looking for a business case to enter the Bakken," Strumpf said. Based on a variety of needs, the group formed by Calumet and including MDU Resources decided to develop a project to construct a topping plant in the Dickinson and Stark County area. "Although this region is home to heavy drilling activity as well as agriculture, it is not served by a refined products pipeline," Strumpf said. Diesel is typically trucked into the region or sent by rail. The nearest refining center is Tesoro Refinery in Mandan, ND, 100 miles to the east. "It seemed to be an area underserved by the market," Strumpf said.

Fidelity Exploration & Production, a subsidiary of MDU Resources, has a substantial position in Stark County and will be supplying a large portion of the crude to the refinery in its early phase. More importantly, production from the Bakken is an ideal feedstock, according to Strumpf. "By its nature, the oil coming from Bakken is light—with a range of 40° to 42° API gravity—and is low on sulfur. It yields a high percentage of distillates that are useful in other areas," Strumpf said. "It's an excellent raw material for a topping plant."

One refining product that motivated the project development was atmospheric tower bottoms (ATBs), or heavy fuel oil. Bakken crude's ATBs are relatively light compared to many other crude feedstocks—in the range of API 20° gravity. They also tend to be free of asphaltenes and heavy metals and are low in sulfur (3,960 ppm), which makes them a premium ATB product.

ATBs can be sold in the bunker fuel market, yet in North Dakota they are more likely suited as a feedstock for refining conversion units. "At the heavy end of the barrel, these ATBs make an excellent upgrade for motor oil due to their high paraffin/low sulfur content," Strumpf said. Calumet operates as a specialty refiner for a range of lubrication products. "Roughly 5,000 barrels a day will be primarily ATBs, and there's not a large market for those in the region," Strumpf added.

Finding a home for this by-product could be challenging, and MDU considers its partnership with Calumet as a way to avert this risk. "Calumet is providing a destination for that part of the barrel that's harder to place from a market perspective," Strumpf said. He added that Dakota Prairie will be the only refinery in the region that's producing heavy fuel oil on a daily basis. For Calumet, the lighter end of the barrel refined into diesel is the by-product. The mutual cooperation will deliver Bakken resources to both the local fuel market as well as Calumet's lube oil refineries in Shreveport, La.

All of the project partners have brought something to the table. "Calumet brought its demand for ATBs and its refining expertise," Strumpf said. MDU Resources brought its experience as a natural gas supply company and as a utility company. "In the great wide open of North Dakota, infrastructure can be a challenge. We've been able to supply both natural gas and electricity to power this operation," Strumpf said. In addition, MDU Resources is doing the major construction in-house through a different subsidiary.

Start up

Strumpf attributes the success of the permitting process to MDU's link to North Dakota. "We've operated safely in the region for more than 90 years," he said. In addition, good working relationships with both political institutions and local communities have contributed to ease of operations.

The refinery is planned to come online in late 2014. As construction ramps up, MDU Resources is now in the recruiting phase for Dakota Prairie Refinery. "We're going to have a need for a number of operations personnel and will require extensive training," Strumpf said. Like other plays in other parts of the country, the workforce will comprise both members from the local community as well as more experienced personnel from outside of the state seeking opportunities.

For Stark County, it's the beginning of a road. Baker sees more opportunities on the horizon. Home to the first US refinery in 35 years, there is interest in developing projects around the new location. Refining growth in the US has developed from expansion projects on existing facilities. "That will most likely happen here," Baker said. "Over the years it will grow into a bigger enterprise."