Future operations planning will measure plan achievability

Refinery operations planning will undergo major changes as increased computing power, and new risk analysis techniques and software reach the planner's desk. Planners will no longer strive for perfectly balanced and economically optimized plans, but will also optimize the "achievability" of the plan.

Risk analysis techniques-long used in the upstream sector to allocate capital-will be brought into the downstream planning process in a quantifiable way. The result will force organizations deeper into contingency planning early in the planning process where it can have the most value.

The result will be operating plans that can be executed with less deviation from plan. Refineries and petrochemical plants will operate smoother and safer and achieve higher profitability.

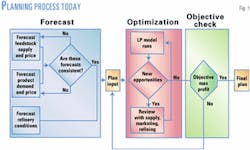

Planning process today

Fig. 1 shows a pacesetter planning process as it exists today in leading organizations. The process starts with a forecast. In operations planning, this forecast usually only looks 3-6 months into the future with a focus on the next 60 days. The forecasts include feedstock availability, product demands, prices, and refinery operating conditions or limits.

The forecasts are reviewed for consistency, and key numbers from the forecasts are used as plan inputs and are given to the linear program (LP) model experts. The LP model is run to optimize an objective function.

Several cycles of team interactions take place as the LP model analysts find opportunities and discuss them with the appropriate departments. An "optimal" plan is produced and approved after several iterations.

Solomon Associates has identified best practices in 22 different areas of refining and petrochemical plant management, including operations planning. Best practices are those activities routinely conducted at facilities that achieve pacesetter status in benchmarking studies.

The difficulty in defining best practices is identifying the characteristics that distinguish pacesetters in a way that does not overspecify what constitutes a best practice. There are many different paths to pacesetter performance, and the definition of best practices must allow for these various paths to success.

Operations planning best practices

A best practices plan has these characteristics:

- It is created with a high degree of collaboration.

- Feedstock supply, product marketing, and refining all have an equal role in plan creation.

- It looks at least 3 months ahead.

- It is prepared in 3-5 working days.

- It is developed to maximize profit.

- It is viewed as an implementation plan and not as a target.

- An actual-to-plan comparison is made each month to identify flaws in plan preparation or plan execution.

- Planning is a discovery process and not just a scheduling exercise.

The best planning organizations will analyze risks by considering various contingency plans. These contingencies are usually examined after the plan has been approved and are only done as time permits. By definition, contingency plans tell us what to do if reality does not unfold as planned. If any contingency plans are generated, they are not implemented until the crisis is obvious.

The root cause of this waiting attitude is the nature of inputs into the various planning models used by industry. Every uncertainty is quantified with a best guess of certain magnitude. Uncertainty is ignored to make an "optimizable" model, no matter how unlikely its predictions may be.

A typical planning meeting conversation is shown in the box. According to the conversation, several issues may have an impact on cat cracker rates for the next month:

- Weather.

- New catalyst.

- Alkylation plant problems.

- Work on the main power substation.

- Crude changes.

- Reformer end-of-run conditions.

- Vacation of key operating personnel.

The problem facing this group was they had to come up with just one cat cracker rate as input into the plan. Any thoughts about a range of possible cat cracker rates were as an afterthought contingency.

It would be useful to the planning group to have information about how each of the issues affected cat rates in the past. It would be even better if they had a prediction of what would happen to cat cracker rates if all these issues happened in one month. For example, what happened the last time a heat wave hit when the cat foreman was on vacation?

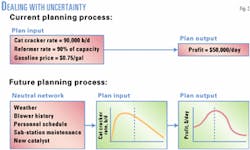

The current best practice planning process does not deal with risk in measurable terms. The process, therefore, has no way to measure the plan's "achievability."

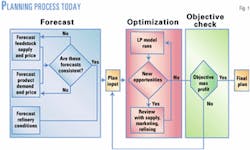

Planning process of the future

The planning process of the future will be able to predict the chances of actually meeting a plan and will force planners to make risk minimization schemes part of the plan instead of contingencies.

The planning process of the future will incorporate neural network and Monte Carlo (MC) techniques to create operating plans with a confidence measure. Management will set objectives to maximize profit and plan achievability. Planners will be forced to deal with contingency plans early and not wait for a crisis to become obvious.

Fig. 2 shows the planning process of the future. Plan input will be generated using neural networks (see box). Each refiner will maintain historical databases of market and refinery conditions. Neural networks will be used to forecast the future based on history and the current situation.

Neural networks are often used today in scheduling gasoline deliveries to service stations. For example, I am scheduling deliveries to a service station in South Bend, Ind. My network has learned that the sales patterns from a specific station are different on weekends when there is a football game in town.

The network does not calculate the football schedule. But if provided this information, the network will choose an entirely different algorithm to estimate sales for home game weekends vs. away game weekends. It has learned this from the historical data in its database. The key is good data and a robust database.

For variables with the greatest uncertainty, a neural network can be structured to forecast a range of possible values-a probability distribution. The probability distributions become part of the plan input, and the LP model is coupled with an MC simulator so that risk can be quantified.

The LP model is formulated in exactly the same manner as before, but uncertain input variables are modeled in terms of a probability distribution instead of a fixed value. Additionally, instead of specifying profit as the objective function to be optimized, one can specify the statistic (mean, standard deviation, or confidence level) associated with the objective function that must be optimized.

LP model runs are initiated using current methods. After each iteration of the LP model, the system moves into MC simulation mode. The MC simulator enters its own iteration cycle in which it randomly selects sets of values from the probability distributions of the uncertain input variables and calculates the distribution of possible outcomes for the objective function.

At the end of the MC simulation, the objective function statistic selected for optimization is calculated. The new value of the objective function statistic is used as a starting point for the next LP model iteration. This LP model/MC simulation cycle continues until the objective function statistic is optimized.

The objective function is profit in a refinery using best practices. The objective function statistic is the mean of the profit distribution and the optimization is set to maximize the mean of the profit distribution.

Again, use the typical plan assumptions meeting summarized in the first box as an example. In the future, the team would use a neural network to generate a probability distribution for cat cracker rates given the specific issues facing the refinery.

In this example, the network would have learned the cat cracker averages only 98% of capacity on 7 out of 10 days where the average noon temperature is over 90

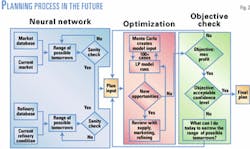

The planning group runs its LP model coupled with MC simulation using the probability distributions for uncertain input variables as input. The group produces a plan with a probability distribution for the mean of the objective function (Fig. 3).

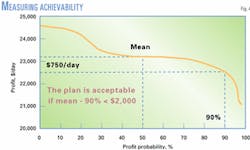

The group might be given an objective for achievability that says the plan must be achievable 9 out of 10 times. One way to define 90% confidence level is to examine the difference between predicted profit at the mean and at the 90% confidence point on the distribution curve.

If the difference is small, less than $2,000/day, the plan is deemed to be 90% confident (Fig. 4).

By focusing on the objective function's probability distribution, the planners are forced to consider risk.

By setting a risk tolerance policy, management forces the planners to reduce risk by taking immediate action. If the plan does not meet the achievability criteria, the planners must ask themselves what they can do today to narrow the range of possible tomorrows (Fig. 2).

In the planning example, the planners may delay adding new catalyst or ask the foreman to delay his vacation depending on how these changes impact the probability distribution of profit estimates.

The author

Michael J. Hileman is a vice-president with Solomon Associates Inc., a division of HSB Solomon LLC, Hartford, Conn. Before joining Solomon, Hileman was vice-president of supply, distribution, and sales for a large independent refiner-marketer. He holds a BS in chemical engineering from Rose-Hulman Institute of Technology in Terre Haute, Ind.

Typical plan assumption meeting

Head planner (Joe) has just convened a meeting with the operations manager (Linda), tech service manager (Fred), and maintenance planner (Travis) to develop the input assumptions for the refinery for the next monthly plan. We are just catching the part of the meeting where the cat cracker is being discussed.

Joe: Well Linda, tell me how the cat is running.

Linda: Everything is right on track. We should beat the plan this month, except for maybe the alky unit. We can't keep the acid strength where it should be. The tech guys are looking into it right now.

Joe: Fred, what do think the problem is?

Fred: We haven't completed our tests yet. But my spies tell me the midnight shift just forgot to add fresh acid.

Linda: (Glares at Fred, but says nothing.)

Joe: Didn't we have to cut cat rates the last time this happened?

Linda: Yeah, but this is different. (It seems Linda knows Fred is right this time, but will protect her people.) I would stay with the same rates for both the cat and alky.

Fred: Not so fast. We are getting that new catalyst in this week and we want to put it in the cat as soon as possible. The economic boys say we will make big bucks with this new catalyst at lower feed rates. You know, the "less is best" theory.

Joe: So great, what should we assume for cat rates next month?

Fred: I wouldn't assume a cut until we prove the economics. Let's not rush into running lower rates just yet.

Linda: Don't worry, we don't plan to cut rates anytime soon.

Travis: I just heard from our scaffolding contractor that City Power, or what ever they call themselves this week, will be doing an overhaul on the main sub next month. Remember what happened last time?

Everyone lets out a big groan.

Linda: Are they going to bump the whole plant off-line again?

Travis: I'll give them a call. But we can't assume the worst.

Joe: Okay, we'll assume no impact from the power sub-station cleaning, but we will need to tell Bob (the vice-president of refining) about this and he'll make us come up with a contingency plan. (Looking at Linda) How's the cat blower doing?

Linda: You know, it tends to struggle on hot days.

Fred: Does anyone know the forecast for next month?

Joe: What, you want me to forecast the weather now? Give me a break.

What was also discussed in other parts of the meeting were the five crude switches planned for the month and that the reformer was at end of run and was assumed to be at 90% capacity for planning purposes. What was not discussed was that the cat cracker foreman was leaving for 3 weeks of vacation starting the middle of next month.

What is a neural network?

A neural network is a process that tries to forecast based on history and can learn from any new data provided to it. Neural networks learn by example. The neural network gathers representative data and then utilizes a suite of algorithms to learn the data's structure.

In simple terms, the neural network will choose from many algorithms the best-fit equation for a set of historical data. Most neural networks can choose from 10 to 20 different algorithms. This best fit is used to forecast a future value for a given parameter.

As new data are entered into the network, the network may choose not only a different set of coefficients for its predictive algorithm, but it may also choose a different algorithm.

By doing this, the network "learns" from the new data.