Western-built jack up to begin Caspian Sea work

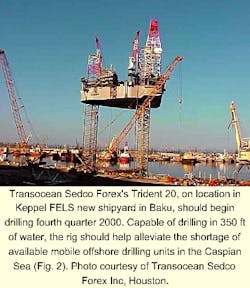

Transocean Sedco Forex Inc.'s (TSF) Trident 20 will spud its first well late this year, becoming the first new Western jack up to enter the Caspian rig fleet.

This brings the total number of Caspian mobile offshore drilling units (MODUs) to five, with two semisubmersibles, two jack ups, and one barge operating in the region.

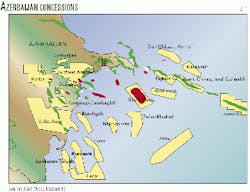

The rig will work for 3 to 5 years as part of the Rig Club 2 vessel-sharing agreement (OGJ, Nov. 8, 1999, p. 63, Table 1). The current drilling commitment includes the following areas (Fig. 1):

- Lankaran-Talysh field operated by TotalFina Elf SA.

- Oghuz field operated by ExxonMobil Corp.

- Lankaran-Talysh field.

- Kurdashi field for Agip SPA.

- Yanan Tava field for the Japanese Azerbaijan Operating Co. (JAOC).

Rig construction

Keppel FELS Ltd. (KFELS) shipyard, Singapore, began building the 500-ft leg sections, jacking mechanisms, jack cases, drill floor, and cantilever in May 1998. Simultaneously, the new shipyard in Baku, owned by KFEL (75%), SOCAR (20%), and Lukoil (5%), began hull construction.

Once the work was completed in Singapore, the drill-floor, jacking units, and cantilever components were sent through the Bay of Bengal and Suez Canal then across the Mediterranean and Sea of Azov in three shipments.

At Mariopal, Ukraine, the components were offloaded onto river barges then hauled through the Don-Volga Canal system. Once they reached the Volga River, the units then departed for Baku from Astrakhan. The total trip encompassed 7,350 miles and each shipment took between 46 and 52 days. Once the Singapore components arrived in Baku, full rig-construction activities began.

"This is the first time that a western jack up has been built in Baku (Fig. 2)," Bill Thomson, project manager for TSF's Trident 20, told OGJ. "Everything was installed here including the piping, hull, quarters, drilling equipment, and helideck (see Trident 20 Rig Specifications)."

Drilling systems

Drilling systems include a zero-discharge system as required by environmental guidelines. Additionally, the rig will use a 15,000-psi blowout preventer stack. "BP Amoco tells us that the Caspian Sea has some of the toughest drilling conditions in the world, even tougher than the North Sea," he said, referring to the tight pore pressure-fracture gradient profiles in the Shah Daniz field.

Geohazardous conditions associated with unstable seabed conditions, mud volcanoes, and high-pressure sands must also be avoided or overcome.

Pipe-handling equipment includes a Canrig Inc. retractable top drive that works in tandem with a Maritime Hydraulics bridge crane. "This equipment will allow drilling crews to pick up a joint of pipe without waiting for the top drive to clear the top of the incoming tool joint," Thomson said.

"We can also move the rig with a full (complement) of drill pipe racked back in the derrick." The rig, however, does not have offline stand-building capabilities. "We are working in an extremely remote part of the world and have to keep the technology simple, reliable, and easy to maintain," he said.