Drilling Market Focus: European companies garner contracts for new rigs

Some of the newest European rig designs feature highly automated integrated systems that are more efficient and safer than traditional rigs, and can be operated with fewer workers. Streamlining the weight and size offers better mobility, and innovative design concepts offer versatility in running straight pipe, coiled tubing, or even support for pipe lay operations. New ideas from rig designers and manufacturers help to reduce construction and operation costs, meet increasingly stringent environmental requirements, and increase the safety of drilling operations.

Operators and drilling contractors want rigs that:

• Can rig-up and move quickly.

• Are highly automated and require fewer personnel to operate.

• Have small footprints.

• Are quieter and more efficient.

• Offer zero or minimal discharge systems.

• Can provide integrated services.

New drilling rig designs with these features from established European companies could alleviate demand for land drilling rigs in many parts of the world. In 2005, we see new rigs from The Netherlands and Italy entering the US rig market.

Huisman-Itrec

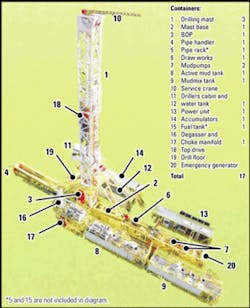

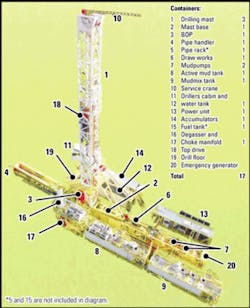

Netherlands-based Huisman-Itrec has designed and built an innovative new containerized casing while drilling rig suitable for land and offshore use. The LOC 250 is the first full drill rig built by the company, in conjunction with Houston-based Drillmar Inc.

The 250-tonne hook load rig was designed by Huisman-Itrec and partly manufactured at the Huisman Konstrukce SRO facilities in Sviadnov, Czech Republic, and assembled and tested in the Huisman yard in Schiedam. It was demonstrated for the public on Oct. 6, 2005 in Schiedam (Fig. 1).

The compact-sized rig can be transported in 17 ISO containers (20 ft by 40 ft), and a rig move can be accomplished within 24 hr. The LOC 250 can be run with five crewmembers. The rig is completely self-erecting; no cranes are required. It includes Tesco’s casing while drilling technology and top drive and a fully automated pipe-handling system. Automated power slips are incorporated in the rotary table. The LOC 250 can trip drill pipe at 2,000 ft/hr. It has two 800-hp mud pumps.

The new rig will drill for US-based Fidelity Exploration & Production Co., a subsidiary of MDU Resources Group Inc., in South Texas later this year. Huisman-Itrec representative Fred Kofman told OGJ that a second rig of the same design is currently under construction.

Huisman-Itrec specializes in complex offshore construction projects, including heavy lift and offshore mast cranes, offshore pedestal cranes, pipe lay systems, and drilling equipment. Among the company’s recent projects was the multi-purpose tower (MPT) drilling tower on Cal Dive International Inc.’s Q4000 multiservice vessel, and pipe-handling equipment on Petrodrill Engineering NV’s Pride Brasil and other semisubs. The MPT is a steel box girder tower that takes the place of a traditional derrick, with a smaller footprint, lower weight and center of gravity. The MPT can accommodate flex lay, J-lay, and coiled tubing, as well as its primary function as a drilling tower.

Huisman-Itrec is also working on basic engineering of the JBF 10000 drilling “rig of the future” (Fig. 2). This compact, deepwater semisubmersible has only 60% of the displacement of a 5th generation semisub, and will be capable of drilling in 10,000 ft water. The fully automated drill pipe handling system is designed to run 135-ft pipe stands in a box mast drilling tower, similar to the MPT on the Q4000. The JBF 10000 also features a zero-discharge fluid system.

Drillmec rigs

In March 2005, Italy’s Drillmec SPA announced contracts with US-based companies for three new hydraulic drilling rigs, totaling $9.6 million. Cheyenne Drilling LP is purchasing two rigs; the third contract is with Envirosafe Drilling LP.

Prior to the US contracts, China National Petroleum Corp. ordered an innovative drilling rig as well as conventional technology from Drillmec for $6.5 million. Drillmec also signed contracts for $46.7 million for new rigs in Algeria, through EDRA SRL (see “Bentec” below).

Drillmec is a recent offshoot of the Trevi Group, consolidating operations that were previously handled by Soilmec. In January 2004, the Trevi Group was restructured and all oil, gas, and water drilling operations were reorganized under Drillmec. Soilmec retained administration of ground engineering equipment and services.

US-based Soilmec Branham Inc. was formed in 1999 when Italy’s Soilmec Group purchased Branham Industries, based in Conroe, Tex. Many rigs now working worldwide were manufactured at the company’s facility in Conroe.

Drillmec now manufactures drilling components and rigs predominantly at its facility in Gariga di Podenzano, near Piacenza, Italy. The facility is an API -authorized manufacturer of drilling and well servicing structures.

Drillmec’s latest designs include the fully automated HH-series and trailer-mounted G-Advance series of hydraulic rigs. The new, light rigs are equipped with hydraulic hoists, top drives, telescoping masts, automatic slips, constant weight-on-bit, and the ability to handle both pipe and casing.

Company representative R.V. Brinkerhoff told OGJ that the hydraulics for Drillmec are sourced from Germany, but the engines come from various manufacturers. He said that the hydraulic rigs are “very competitive cost wise” and there is currently a manufacturing backlog of about a year. He noted that the hydraulic rigs have enjoyed a better uptake in Canada and elsewhere outside the US, including Venezuela, Argentina, Bolivia, southeast Asia, and Africa.

Cheyenne Drilling LP recently accepted delivery of a new Soilmec G-105 rig that arrived in the Port of Houston in June 2005. The G-105 is a mobile hydraulic hoist rig with a static hook load capacity of 220,000 lb. Cheyenne’s Bobby Alexander told OGJ the company has about $4.5 million invested in the G-105 rig, and that it’s working for Antero Resources Corp. under a 12-month contract in the Piceance basin. Cheyenne trains its righands on two Walker-Neer top-drive rigs.

The Soilmec hydraulic hoist rig design was developed with the Italian energy group, ENI SPA, through Agip SPA, and Saipem SPA. Five different G-Advance versions are offered, ranging in hook load capacity from 200-500,000 lb (Fig. 3).

Soilmec had delivered more than 20 of these new rigs, including 12 to North Africa, 3 to Italy (Agip), 2 to Venezuela, and 1 each to Siberia, Australia, Iceland (Jardboranir IDC), and the US.

Drillmec will soon deliver a second rig, a G-200, to Cheyenne Drilling. Alexander told OGJ that the rig left Italy on Oct. 5 and will take about 3 weeks to get to the Port of Houston. It will begin a 30-month contract for Occidental Petroleum Corp. in the Piceance basin. Cheyenne will have about $7 million invested in the G-200, and expects a 4-year payout.

The G-Advance series represent a further refinement of the older G-series hydraulic drive mobile rotary drilling rigs. Those lighter rigs offered hook load capacities in the range of 44-106,000 lb (G-15, 25, 28, 35, 45, 48).

Soilmec also offers an older series of diesel or electric drive MAS rigs with hook load capacities of 550,000-1.5 million lb (MAS 4000, 5000, 6000, 7000, 8000). The company’s MR series are mobile workover drilling rigs with mechanical drive and hook load capacities of 33-397,000 lb (MR-1500, 2500, 3500, 4000, 5000, 7000, 7000XS).

CROSCO rigs

Zagreb, Croatia-based Crosco Integrated Drilling & Well Services Co. Ltd., part of the INA Group, operates a fleet of 48 land rigs and three offshore rigs.

Crosco has regional headquarters in Albania, Egypt, Italy, Libya, Morocco, Oman, and Tunisia. The company has drilled more than 4,000 wells since beginning onshore operations in 1932 and offshore operations in 1972.

Crosco’s three offshore rigs include the Panon jack up, the Labin jack up, and the Zagreb 1 accommodation semisub. Crosco controls 50% of Noble Crosco Drilling Ltd., the operator and owner of the jack up rig Panon. Crosco also manages the Carl Norberg jack up for Sugar Land, Tex.-based Noble Corp.

The Labin jack up is a Levingston 111-C design that was built in 1985 at the Viktor Lenac shipyard in Rijeka, Croatia. The rig was reconstructed over 6 months at the Nauta Lamjana shipyard in Zadar, Croatia, beginning in November 2003. The hull size was increased to 210 x 217 ft from 197 x 184 ft; the cantilever skid was increased to 55 ft from 35 ft, the operating sea depth was increased to 329 ft from 300 ft with leg extensions, and the accommodations upgraded to 100 persons from 77 persons.

Three years ago, Crosco added three land drilling rigs to its fleet: MIDCO 501, EMSCO 602, and IDECO 301. A company representative told OGJ in September 2005 they have no plans to add or upgrade the current fleet and that Crosco does not offer coiled tubing drilling at this time.

In July, Crosco announced that two of its land drilling rigs, National 403 and 801, would be used for Falcon Oil & Gas Ltd.’s subsidiary, TXM Oil and Gas Exploration’s Hungarian drilling program. Crosco’s National 403 is a 1,600-hp rig, which will be used to drill two shallow wells and possibly a third in the Tisza license area.

Crosco’s National 801 is a 3,000-hp rig that will drill a deep well in the Mako license area and potentially three additional wells.

Crosco’s National 801 was drilling in Albania for OMV Albanien Adriatic Sea Exploration GMBH in late 2004. Crosco has provided drilling services for four different operators in Albania since 1994.

Crosco set an onshore drilling record with the Dumre well in Albania, drilled to 6,119 m (20,075 ft) in the 1980’s. The company still holds the record for the deepest offshore well drilled in Europe-7,305 m (23,967 ft) offshore Italy.

Eiffel FMWR

Eiffel Construction Metallique SA, a subsidiary of the Eiffage Group, builds platforms and rigs at its facility in Fos-sur-Mer, southern France. Eiffel licensed a new design from French drilling engineering company Dolfines SA for a fast moving workover rig (FMWR). The rig has a small footprint and can be transported using a supply vessel and a platform crane. It does not require a heavy crane or crane barge.

Eiffel built the first FMWR, ES 1250, for ENI Gas BV’s Western Libyan gas project, and shipped it late last year. The 1,000 tonne rig was installed on the Sabratha platform about 110 km off the west coast of Libya for development drilling in the Bahr Essalam field (Fig. 4). It began drilling in January 2005.

Lloyd’s Register EMEA verified the installation of the single integrated deck for the Sabratha topsides only 3 months earlier, in October 2004.

In May 2005, Crosco announced that it was providing management, operation, and maintenance services for the FMWR on the Sabratha platform. Crosco is also providing onshore drilling services with its 2,000-hp EMSCO 604 rig in Libya’s Elephant field.

Bentec rigs

Innovative rig designs also arise from Germany’s Bentec Drilling & Oilfield Systems GMBH, based in Bad Bentheim, a division of the Abbot Group PLC. Bentec specializes in manufacturing “fit for purpose” rigs, but also offers a portfolio of land rigs up to 2,000-hp. The company has completed a number of special offshore projects including the Oseberg S platform rig and provided a new derrick equipment set for the Brent Charlie platform.

In May, Bentec announced its completion of the new 2,500-hp T-150 rig for the Mittelplatte drilling and production island in the German North Sea (OGJ, June 20, 2005, p. 49).

According to Abbot Group’s interim results released Sept. 15, 2005, Bentec has a contract with KCA Deutag to build two Bentec-designed hybrid rigs for the Russian drilling market. The first rig will be delivered in December 2005, the second in January 2006. Bentec is also building a highly mobile drilling unit for KCA Deutag to fulfill an OMV drilling contract in Austria; that rig will be delivered in May 2006.

Bentec is also supplying components for a mobile rig in Kazakhstan and components for four drilling rigs for the EDRA Alliance for Entreprise Nationale des Travaux aux Puits (ENTP) in Algeria.

In Oman, Bentec has launched a joint-venture company for rig repair, servicing, and upgrading. European rig designers and manufacturers already show a lot of promise for 2006.✦