Complex, redundant AST regulations require thorough monitoring by facility operator

New laws and regulations governing storage and transportation of liquid petroleum often result from incidents so dramatic they draw the attention of the general public. This has been especially true in the US; the Exxon Valdez oil spill in 1989 resulted in the 1990 Oil Pollution Act on the federal level and other more stringent laws and regulations in some individual states.

The result, especially in the past 15 years, is a patchwork of federal and state regulations and oversight bodies. The regulatory scene for terminal operators is complex and intertwined with contradictions, overlaps, interpretations, and often confusion. This article will attempt to clarify this situation.

Dealt with here are marine and bulk liquid terminal facilities as well as pipeline breakout terminals regulated by the US Department of Transportation's (DOT) Office of Pipeline Safety (OPS).

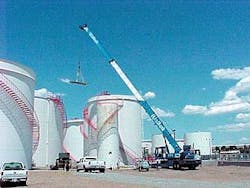

But many of the issues and principles discussed here apply to most aboveground storage tank (AST) facilities or those portions of other facilities that store petroleum or chemical products, such as refineries, chemical plants, or airport fuel terminals.

This article addresses the fundamental regulatory and compliance issues of which the tank and terminal operator should be aware. It also discusses best practices and why operators should consider adopting them, whether or not they are specifically prescribed by regulation, in order to reduce risks and liabilities.

Regulation of aboveground storage tanks (ASTs) is more complex than for underground storage tanks (USTs); oversight of the latter resides under 1986 amendments to the 1976 Resource Conservation and Recovery Act (RCRA). The amendments enabled EPA to address environmental problems that could result from underground tanks storing petroleum and other hazardous substances.

Various regulations apply to ASTs, including RCRA, the Clean Air Act (CAA; originally published as the 1955 Air Pollution Act, then later as the 1963 Clean Air Act with amendments in 1970 and 1990), the 1972 Clean Water Act (CWA), and the 1990 Oil Pollution Control Act (OPA90).

At least five different federal agencies or offices, including the US Environmental Protection Agency (EPA) and the departments of Labor and Transportation are involved in these regulations.

Legislation such as the Above-Ground Storage Tank Consolidation and Regulatory Improvement Act (1996) was to consolidate some of these regulations and provide greater protection than does current law against underground releases from aboveground tanks. The law failed to be enacted, and the regulatory complexity increases for the terminal operator.

The American Petroleum Institute (API), however, developed in July 1994 an important standard, API 2610 "Design, Construction, Operation, Maintenance, and Inspection of Terminal and Tank Facilities" that ties together most of these requirements.

In addition to serving as a checklist of best practices for the terminal operator, it serves as reference to other relevant codes and standards. Regulators and operators should be aware of and review API 2610.

There are nearly 25 states that have AST rules of some sort.1 These states have been meeting for the last 3 years in Florida under the auspices of the National Governor's Association. This association of state AST directors is meeting this year to formalize and name this association.2

(Note: While all of the rules and regulations discussed here could be referred to as "AST rules," the term is more commonly applied to regulations pertaining to the integrity of the tank bottom in order to prevent the stored liquid from leaking into the ground.)

Philosophy of regulations

It is appropriate, before considering the codes, standards, and regulations applicable to tank facilities, to address how new or existing facilities are treated.

Most major codes, standards, and regulations use the concept of "grandfathering" to allow existing facilities to be exempt from newly enacted requirements. Because practices and technology advance with time along with codes, standards, and practices, older facilities generally have built-in obsolescence.

For example, cast iron valves and fittings used to be common in petroleum terminals. All current fire codes, however, prohibit use of cast iron because of the possibility of brittle failure during a fire.

But facilities do not necessarily have to remove them. Although certain codes and standards may consider such items "grandfathered," most operators would replace the older cast iron fittings as the result of a benefit-to-cost analysis or to minimize risk.

In the case of existing facilities, the owner can make a site-specific, case-specific analyses to determine if the risks of the older equipment, layout, spacing, systems, or processes are commensurate with the acceptable risk levels. Alternatively, the owner or operator can install counter measures that reduce the risk associated with older material or designs.

When the tank facility owner builds a new terminal or simply installs new equipment in an existing facility, the modifications are built to the current standards, codes, and regulations. Permitting and siting as well as notification to the appropriate authorities will also be required. In some cases, depending on the magnitude of the new additions or modifications, existing facilities at the location may have to be upgraded and brought into compliance with current regulations. Spacing of equipment for new facilities or modifications to existing facilities are usually controlled by fire codes.

It should be noted that the type of tank internal floating roof can have a major impact on the required spacing between tanks and properties lines, important buildings, and rights-of-way. Steel annular pontoon and double deck floating roofs (as opposed to pans, open bulkheaded pans, and aluminum floating roofs) receive the most favorable spacing requirements under fire codes (NFPA 30 para. 2.3.2).

Regulatory development

It is important to distinguish between "prescriptive" and "performance-based" standards.

Prescriptive requirements stipulate (prescribe) a specific measure or measures that must be complied with. These are sometimes referred to as "one size fits all" rules in that they impose a fixed, standard rule, regardless of how it may fit the individual problems or circumstances.The clear disadvantage of this approach is that it may be grossly inefficient or even counter-productive. The advantage to the prescriptive approach is that it is simple to understand, easy to apply, and easy to enforce. Facilities can implement compliance with predictable costs and assurance of approval, and regulators can readily ascertain when compliance has been achieved.

- Performance-based requirements, on the other hand, specify a goal or required outcome but allow flexibility in achieving the goal. This approach holds the promise of "smarter, cleaner, and cheaper" solutions because it allows individual facilities to adapt measures to fit compliance.

The flexibility can be a two-edged sword, however. Allowing room for interpretation on the part of industry in how to achieve the goal also means that there is room for interpretation by the regulator on whether the measures taken are adequate. Thus, while a performance-based approach leads to efficient use of resources, getting regulatory approval may be uncertain.

The performance-based approach depends upon technical competence and political integrity on the part of all stakeholders. When either technical or political integrity is suspect, there is a corresponding tendency toward a prescriptive approach.

Although there may be a place for inclusion of prescriptive measures as a safety valve in a climate of mistrust, there should always also be the opportunity to rise above the rancor and pursue a performance-based alternative. The one-size-fits-all approach must allow for adaptation in those cases where it clearly does not fit.

Development of industry standards is the almost idealized case in which performance-based rules are created. An accompanying discussion next describes industry's process for creating performance-based rules and standards.

As an example of prescriptive vs. performance-based rules, consider the requirement for internal inspections of tanks according to API 653 discussed separately.

API 653 uses an internal inspection interval that is performance-based when corrosion rates are established. The interval can typically vary from 10 to 20 years depending on corrosion rates and other factors. A few states, however, have adopted API 653 but set the internal inspection interval at a shorter period: for example, 10 years regardless of corrosion rates, the presence of double bottoms, and leak detection or other means of corrosion mitigation in place.

The belief system that fosters the prescription for the short internal inspection interval is that if internal inspections reduce the potential for tank bottom leaks, then a higher frequency than specified by API 653 is better. Although the internal inspection interval has a significant safety factor against errors in assessing corrosion rates built into the time period, the prescriptive approach assumes that boosting this safety factor many times is a proper approach.

This belief in "more is better" is not necessarily true. While more frequent internal inspections may sound "proactive," the higher frequency of internal inspection creates other problems.

Some of these are:

Cleaning a tank produces a significant volume of hydrocarbon vapor emissions as well as liquid waste, which is sometimes hazardous waste under RCRA. This waste ultimately must be absorbed or transformed by the environment.

When a tank is taken out of service for an internal inspection, it must be cleaned. The tank will usually be out of service from several weeks to several months. Arbitrarily increasing the frequency of internal inspection to say 5 or even 10 years across the entire tank population forces tank operators to build more tanks to cover the reduced available operating time.

The increase in tanks results in increased potential for leaks, incidents, and problems as well as more hazardous waste and emissions from the excessive tank cleanings.

Tank cleaning is dangerous work. The potential for someone to be hurt increases directly with the number of tank-cleaning operations. Tank cleaning should be done only as much as necessary to reduce exposure to worker injury.

No credit is given to the effectiveness of many of the methods of preventing and detecting bottom leaks from ASTs in common use such as double bottoms, cathodic protection, coatings and liners, or various methods of leak detection.

A prescriptive regulation actually hinders some of the good practices, such as installing double bottoms, because there is no incentive on the part of the terminal operator to upgrade. The regulation has pre-empted the alternatives and potential best practices by setting one requirement for all tanks regardless of the factors involved.

While a higher frequency might be warranted in some circumstances, it may not be in others. So the higher frequency internal inspection is not applied effectively because it is applied more often than necessary to many or most tanks. The benefit-to-cost of such a regulation may be low.

It is important that both regulators and industry representatives understand that any option chosen for a rule or regulation have both costs and benefits that should be considered objectively, such as by risk management and benefit-to-cost analysis.

Types of regulations

For discussion purposes, regulations pertaining to AST facilities fall into the following categories: fire codes, environmental Clean Water Act, environmental Clean Air Act, OSHA, US Coast Guard, and regulations relying on industry standards.

Fire codes

Before the CWA and CAA, the AST rules stemmed primarily from national fire codes. Fires were common in building structures as well as industrial structures; wooden and open top tanks were often used for petroleum storage. The responsibility for fire control was that of the fire department or the authority having jurisdiction (AHJ).

As a result, the AHJ had responsibility for all kinds of structures, including storage tank facilities. Because AHJs tend to be regionally organized along the lines of state and local governments, application of fire-related regulations and rules for storage tanks tends to vary considerably. There is no single national fire code. Rather, local and state governments adopt codes developed by one of three organizations:

- National Fire Protection Association (NFPA), which publishes NFPA Code 30 Flammable and Combustible Liquids Code, 2000 Edition.

- International Codes Council (ICC), which publishes the International Fire Code 2000 (IFC).

- Western Fire Chiefs Association (WFCA), which publishes the Uniform Fire Code 2000 Edition (UFC).

Currently in progress is a merger between NFPA and UFC codes. The rules for AST facilities are similar but not identical in these codes.

CWA regulations

Many regulations stem from the CWA.

Two that are significant for the present purposes for the petroleum terminal operator are the Spill Prevention Control and Countermeasures (SPCC) and regulations relating to secondary containment.

Significant revisions to the existing SPCC regulations are in progress by EPA and the Office of Management and Budget (OMB) and are to be released this year. Section 311 of the CWA, as of now (Fig. 1), addresses pollution from oil and hazardous substance releases, providing EPA with the authority to establish a program for preventing, preparing for, and responding to oil spills that could affect navigable US waters.The Office of Emergency and Remedial Response runs EPA's oil spill program. The program includes regulations for notifying authorities of oil discharges, the Oil Spill Prevention, Control, and Countermeasures (SPCC) program, and Facility Response Program (FRP).

The SPCC program applies to facilities that have large oil storage capacities and that could reasonably be expected to discharge oil into US navigable waters. SPCC regulations require each owner or operator of a regulated facility to prepare an SPCC plan. The plan must address the facility's design, operation, and maintenance procedures established to prevent spills from occurring, as well as countermeasures to control, contain, clean up, and mitigate the effects of an oil spill that could affect navigable waters.

OPA90 was signed into law largely in response to rising public concern following the Exxon Valdez incident. The legislation improved the nation's ability to prevent and respond to oil spills by requiring facility owners or operators to prepare, and in some cases submit to federal agencies, facility-response plans (FRPs) addressing a worst-case discharge of oil. It also improved coordination between authorities responding to discharges of oil into navigable waters.

As a result of the OPA, industry and governmental agencies (DOT, EPA, MMS, USCG) worked together and developed a common protocol for a drills and exercises program. Overlapping OPA, CAA, and OSHA requirements for emergency response contingency plans may be consolidated into an Integrated Contingency Plan (ICP) that typically consists of a basic emergency response plan plus cross reference tables for each agency. (See www.epa.gov/ceppol.)

In 40 CFR 112, secondary containment guidelines essentially state that all bulk storage tank installations should be constructed so that a secondary means of containment is provided for the entire contents of the largest single tank plus sufficient freeboard to allow for precipitation.Diked areas should be sufficiently impervious to contain spilled oil.

Secondary containment was originally required by NFPA to contain major spills of flammable or combustible liquids to reduce the potential damage that fires in petroleum terminals could have and to allow for better fire fighting.

Secondary containment structures are typically earthen berms or concrete block or other walls constructed around the tanks and the perimeter of the facility. They are designed to contain the volume of the largest tank should it rupture. In NFPA rules, the secondary containment berms or walls must be sufficiently strong to hold the liquid without collapse and to be "liquid tight."

In the SPCC rules, the concept of secondary containment was adopted for the purpose of capturing a major spill and preventing it from spreading offsite and to make cleanup easier.

In most environmental rules related to secondary containment, the definition of "impermeability" has become an important issue. In the SPCC rules, the secondary containment must be "sufficiently impermeable" to prevent the spilled liquid from entering the ground water table. Determining what this means requires that some kind of engineering evaluation be made to determine what is "sufficiently impermeable."3

Several states (and some EPA enforcement personnel), however, have interpreted this to require secondary containment liners. While it can be credibly argued that in certain circumstances, such as a terminal overlying a drinking water aquifer, that secondary containment liners have a benefit, the liner as a general requirement for providing a risk reduction for the environment is unsubstantiated and unproven.

The liner requirements add a significant cost for the terminal operators but may not result in any positive benefits. API Publication 341 "A Survey of Dike-Area Liner Use at Aboveground Storage Tank Facilities" (February 1998) provides a good summary of the effectiveness of liners where they have been installed.

CAA regulations

Rules pertaining to air emissions are generally promulgated under the Clean Air Act (CAA), but there are areas of overlap with other EPA offices. ASTs that store hazardous waste, for example, may be subject to air rules under RCRA in addition to the CAA rules. The Toxic Release Inventory (TRI) requirement for annual reporting of emissions is administered under Emergency Planning and Community Right-to-Know Act (EPCRA) Section 313 (Superfund Amendments and Reauthorization Act [SARA] Title III).

The majority of the federal air rules for ASTs, however, have been generated under the CAA, as shown in Table 1. There are also state and local Reasonably Available Control Technology (RACT) rules for SIP compliance in areas of volatile organic compound (VOC) nonattainment.

Regulations continue to be promulgated on both a national and a local level, including the recently proposed National Emission Standards for Hazardous Air Pollutants (NESHAP) rule for the organic liquids distribution (OLD) industry.4

OSHA

The actual applicable US Occupational Safety and Health Administration (OSHA) standards involve a complex array of standards and provisions. Most operators of larger terminals have full-time safety and compliance managers who spend significant time and effort ensuring that the OSHA regulations are appropriately incorporated into their work processes.

Smaller terminal operators must carefully examine the suites of relevant standards to ensure that they are in compliance. A useful suggestion for the operator is to review carefully the OSHA web site and check the applicability of each of the standards that might apply.

Following are the two primary functions of the OSHA act:

- Setting standards.

- Conducting workplace inspections to ensure that employers are complying with the standards and providing a safe and healthful workplace.

OSHA standards require employers to become familiar with standards applicable to their establishments, to eliminate hazardous conditions to the extent possible, and to comply with the standards.

Compliance may include ensuring that employees have and use personal protective equipment when required for safety or health. Employees must comply with all rules and regulations that are applicable to their own actions and conduct.

States with OSHA-approved job safety and health programs must set standards that are at least as effective as the equivalent federal standard. Most of the states adopt standards identical to the federal ones

Even in areas where OSHA has not promulgated a standard addressing a specific hazard, employers are responsible for complying with the OSH Act's "general duty" clause: Each employer "shall furnish…a place of employment which is free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees."

US Coast Guard regulations

The secretary of the US Department of Transportation delegated responsibility to the US Coast Guard to draft and enforce regulations for marine transfer facilities. These regulations apply to fixed facilities that transfer oil or hazardous material in bulk to or from vessels with a capacity of 250 bbl or more. The regulations that apply to these fixed facilities are outlined in 33 CFR Parts 154 and 156.

The physical structures, piping systems, and equipment used to transfer oil or hazardous material are regulated by 33 CFR 154 and include the transfer dock, control stations, and personnel shelters used during the transfer operation.

The piping system regulated by 33 CFR 154 includes the system's pressure-relief valves, pressure gauges, and emergency shutoff systems.

Coast Guard jurisdiction extends to the first valve inside the EPA SPCC secondary containment, as established in a Memorandum of Understanding between DOT and EPA. That memorandum establishes the DOT's responsibility for the entire portion of the facility that is used to transfer oil to or from a vessel. This area is known as the "transportation-related" portion of the facility.

The Coast Guard further requires the facility to prepare, submit, and gain approval of a facility operations manual from the captain of the port. The manual specifies, among other elements:

- Equipment inspection and testing requirements.

- Person-in-charge (PIC) training qualifications.

- Dock spill-containment system requirements.

- Transfer procedures and documentation.

- Dock fire-protection requirements.

- Piping and hose specifications.

The Coast Guard annually inspects the facility and reviews the operations manual. Formal processes exist for the captain of the port to require facilities to modify procedures and the operations manual to comply with requirements specified in 33 CFR 154 and 156.

Facilities must have formal processes they follow to submit and receive approval for changes to procedures, the operations manual, or to apply for alternative methods of complying with requirements. Coast Guard regulations apply to terminals or facilities that have piping over navigable waterways of the US.

Industry standards

On Jan. 2, 1988, at a barge terminal in Floreffe, Pa., a newly recommissioned storage tank suddenly collapsed and released 3.9 million gal of diesel oil. Although the earthen dike contained most of the diesel oil, an estimated 750,000 gal spilled into the Monongahela River and eventually flowed into the Ohio River.

The publicity and costly consequences of this failure caused widespread concern about the safety of all aboveground storage tanks. Responding to the aftermath of this event, petroleum industry engineers and API updated existing standards and developed several new standards.

Emerging in the last few years are a few new and significant trends at both the federal and state levels regarding tank facility regulations.

One such development is the enactment of Pipeline Terminal Breakout Tank rules promulgated under 40 CFR 195 which apply to tanks associated with cross-country pipeline terminals. Simply stated, pipeline "breakout tanks" are those that are an integral part of the pipeline system such as tanks that receive liquids from one pipeline for input to another pipeline and tanks that are used for pipeline pressure relief.

The new breakout tank regulations, promulgated in 1998, are significant in that they apply to all breakout tank facilities under jurisdiction of the DOT. In a sense, they have the same impact an AST Act would have had in that these rules apply to every state, but they only apply to a category of tanks directly associated with pipelines regulated by DOT.

Another notable development occurring at the federal level is the anticipated publication of revisions to the existing SPCC regulations. The SPCC applies to almost all AST facilities and therefore has an impact on petroleum facilities as universal as if a federal AST Act had been published.

The significant aspect of the DOT breakout tank regulations is that they rely heavily on the use of industry standards (Table 2). On the other hand, the SPCC does not refer to specific industry standards but leaves it up to the tank facility operator to determine which are applicable.

These rules have had a high level of industry acceptance because they tend to be performance based and founded on industry standards.

On the state level, a few states have developed significant new or revised tank regulations. The drivers for regulations in these states tend to be groundwater or service-water protection, major incidents, or political concerns. These states tend to be precedent setting for rulemaking in other states.

A few examples are Alaska and Florida. Alaska's rules were driven primarily by the Valdez incident. Florida's rules are driven by the need for groundwater protection and by contamination incidents.

While these states use industry standards, they often go further to prescribe additional measures that are often the subject of heavy debate. An example of this is the requirement for a fixed internal inspection interval for ASTs.

Table 3 lists states having requirements for inspections of tanks, piping, and pressure vessels.

Risk management

Many rules or regulations are promulgated to address and mitigate actual or perceived problems and are often associated with incidents that have occurred. Rulemaking should ask several questions:

- How frequent has the incident or problem occurred?

- How serious is the incident or problem?

- What are the root causes and what scenarios lead up to the incident?

- What are the health and safety threats?

- What are the business and financial impacts?

- How do we rank the risk of these various events?

- Can these events affect how business is done in the future?

A method for systematically answering these questions is found in the principles of risk analysis and risk management. Risk management is done everyday informally every time we consider the risks of any activity, such as crossing the street. However, it is an area that is receiving wide effort and attention at the industry and regulatory levels because it is a way to prioritize the rulemaking using a consensus process.

Numerous publications exist describing various methods of risk management. API is currently addressing a quantitative methodology of evaluating risks at terminals. API Publication 340 presents a comprehensive overview of the subject of risk management at petroleum storage terminals.

This document identifies various occurrence scenarios (sources of leaks) that might occur at a terminal and then lists possible control methods that could be used, along with a qualitative comparison of relative costs as well as operational and maintenance considerations.

Current scene

Perhaps the best advice for the terminal operator in this scene of complex and sometimes contradictory rules and regulations is to maintain a priority on safety, health, and environmental protection and ensure that every aspect of design, installation, operations, maintenance, inspection, and changes are continually reviewed with these values in mind.

A review of API 2610 is probably the best place to start because it is a comprehensive list of best practices that the terminal can use to benchmark itself against average industry practices.

It is also very clear that more communication between regulator and industry representative is needed. When a legitimate and fair process, such as the consensus standards process used by most standards development organizations, can be applied for regulatory rulemaking, better regulations will result, and there will be fewer complaints from both sides.

This will take a willingness to share and communicate as well as time, effort, and resources on the part of industry and the regulatory sector.

References

- Aboveground Storage Tank Guide, Thompson Publishing Group, Washington, DC.

- Information about this forum or other similar AST regulatory issues is available from the Florida Department of Environmental Protection, Storage Tank Regulation Section.

- Myers, P.E., Mikkola, C. A., Power, B. F. "Secondary Containment Liners for Tank Farms - A New Approach, " Hydrocarbon Processing, May 2000, pp. 81-84.

- 40 CFR Part 63 Subpart EEEE (proposed), National Emission Standards for Hazardous Air Pollutants: Organic Liquids Distribution (non-Gasoline).

The authors

Jerry M. Engelhardt is a regulatory and legislative issues consultant with Kinder Morgan Energy Partners and formerly with Santa Fe Pacific Pipelines, bought by Kinder Morgan in 1997. He has also held positions with Macmillan Oil Co. and Shell Pipeline. He holds a BSCE (1965) and an MS (1966) in industrial administration, both from Purdue University, West Lafayette, Ind. Engelhardt has served on several API committees including environmental, health, and safety; public awareness; storage tank task force (chairman); and the working group for preparing a terminal risk-assessment publication. He has also chaired the pipeline committee of the Western States Petroleum Association and served on the board of directors for the Independent Liquids Terminal Association.

Phil Myers is a codes and standards specialist at ChevronTexaco Corp. He holds a chemical engineering degree from the University of California and is a registered professional engineer in California. Among his many industry activities, he chairs the API subcommittee for tanks and pressure vessels and serves on the API storage tank task force and the task force's leak detection work group for aboveground storage tanks.

Robert L. Ferry is a senior partner of TGB Partnership, consulting engineers, which he cofounded in 1993. Previously, he was a vice-president with Conservatek Industries Inc. and an engineer with Pittsburgh-Des Moines Steel Co. Ferry holds a BS (1974) in civil engineering and a master of engineering (civil; 1975), both from Cornell University, Ithaca, NY. He is a registered professional engineer in North Carolina.

How performance-based rules are developed

Development of API standards is an example of a process that generally results in "performance-based" rules. Understanding this process requires a quick look at the American National Standards Institute (ANSI) accreditation process that accredited national standards-writing organizations use.

Elements

This process results in a good model for any organization developing effective rules or standards. The key elements are:

- There must be various groups of stakeholders with appropriate expertise properly proportioned in committee including representation from users, manufacturers, and general interest.

- The committee must hold regularly scheduled and noticed meetings.

- The final draft code must be balloted to the appropriate oversight committee when completed.

- A substantial majority must favor the code or standard for it to pass.

- A fair and formal process for resolving all negative votes must exist and every effort must be made to resolve issues associated with the negative votes.

- No practices which could give an unfair trade advantage or restrictions to a particular group of affected stakeholders are allowed, and anti-trust rules must be strictly adhered to.

Result

It is clear that this process, by its nature, requires substantial time and effort to implement, but the result provides more flexibility, has more credibility, and usually considers the benefit-to-cost issues that are not generally considered by a prescriptive, one size fits all approach.

The process allows all stakeholders the ability to buy into the final document. The consensus process also brings together the necessary expertise and provides a mechanism whereby the committee works out the problems of getting a common denominator of agreement.

API 653 coverage

- Applicability. This standard applies to maintaining the integrity of existing, in-service aboveground petroleum storage tanks.

- Suitability for service. Coverage includes the evaluation of fixed and floating roofs; changes in stored liquid and the effects of changes in density and temperature; evaluation of severely corroded shells for strength, venting, and internal pressure; evaluation and strength of riveted tanks; and bottom evaluation.

- Brittle fracture. This section provides guidelines that can be used to prevent sudden and catastrophic failures due to brittle fracture.

- Inspection. This section provides for three kinds of inspection: informal monthly, formal in-service, and formal out-of-service.

The first two inspections are conducted while the tank is in service and do not interfere with the operation of the tank. The third inspection requires the tank to be cleaned, gas-freed, and removed from service. Both formal inspections must be performed by an API 653 certified inspector.

This section provides rules for setting the inspection interval on internal inspections. The maximum interval is 20 years (if corrosion rates are low). The maximum interval if no corrosion rates are known is 10 years.

- Reconstructed tanks. When tanks are relocated by cutting down and re-welding, the rules of reconstruction apply.

- Repairs or alterations. API 653 provides rules for typical changes to tanks including installation of large door sheets, new nozzles, repair of welds, patching or replacing the bottom, and hot tapping (installing nozzles while the tank is in service).

- Quality. API 653 addresses all aspects of welding and non-destructive examination quality control for any repair or alteration that is done on a tank. It relies heavily on API 650 as well as the welding and non-destructive portions of the American Society of Mechanical Engineers (ASME) boiler and pressure vessel code.