World drilling market absorbing new jack ups

Demand for jack up drilling rigs has pushed up day rates, with 17 newbuilds delivered in 2000-04 and 12 more under construction. Several new designs lead the way, including the Rowan/LeTourneau Tarzan class, Keppel FELS Super B Class, Friede & Goldman's JU-2000, and the Baker Pacific Marine 375. These designs enable deep drilling to 35,000 and perhaps 40,000 ft, in water as deep as 500 ft.

The demand for newbuild and secondhand jack ups and upgrading of existing rigs are driven by a growing interest in natural gas prospecting and development. Contractors continue to upgrade their fleets, selling lower specification rigs. Jack ups now comprise about three-quarters of the worldwide fleet of mobile offshore drilling units.

Rig rates

Contract rates for jack up rigs have risen higher than $50,000/day for most of the fleet.

Rigzone provides average day rates for 12 different categories of jack ups, based on depth capability (to 200, 250, 300 ft or greater) and type (IC—independent leg cantilever; IS—independent leg slot; MC—mat cantilever; and MS— mat slot).

The highest rates are paid for independent leg cantilever jack ups, which comprise most of the world's fleet (282). As of early December, IC rig rates were averaging about $45,000/day for water up to 250 ft, $53,500/day for 300-ft water, and about $68,000/ day for water deeper than 300 ft.

Independent leg slot jack ups are the next priciest, and there are 37 in the market. IS rig rates were averaging $35,500/day for water up to 250 ft, and about $41,000/day for water 300 ft or deeper. There are 45 mat cantilever rigs on the market, leasing for $25,000-36,000/day, and 25 mat slot rigs leasing at rates about $33,500/day.

Jack up day rates are also improving, according to ODS-Petrodata's monthly offshore rig day rate indices. Data published Nov. 12, 2004, show an index of 177 for Gulf of Mexico jack ups in 250-300 ft depth range, based on the average market day rate in January 1994 equal to 100. The day rate index for jack ups in the Gulf of Mexico has not been this high since September 2001, and ODS-Petrodata says, "day rates will continue to rise as operators move to secure rigs for planned drilling programs."

Indices

The ODS-Petrodata North Sea jack up day rate index reached 227 in November, a level not seen since mid-2003. North Sea jack up utilization has been at 100% for 3 months running, fueling the day-rate increase. ODS-Petrodata said "Rates will continue to spiral upward with rig owners in the driver's seat when it comes time to negotiate contracts."

GlobalSantaFe Corp.'s monthly Summary of Current Offshore Rig Economics also shows that jack up day rates continue to increase worldwide. The overall SCORE for October 2004 was 47.7, up 4.3% from the previous month and up nearly 15% from the previous year, and up 105% over 5 years.

The SCORE for jack ups worldwide was 55, down 1.6% from the previous month, but up nearly 17% from a year ago, and up 137% over 5 years.

SCORE compares the profitability of current mobile offshore drilling rig day rates to the profitability of day rates at the 1980-81 peak of the offshore drilling cycle. At that time, SCORE averaged 100%, and new contract day rates equaled the sum of daily cash operating costs plus about $70/day/$1million invested.

Fleet utilization

As of Dec. 3, worldwide jack up utilization was 89.9%, and 346 of the global fleet of 385 jack ups were under contract, according to ODS-Petrodata. On a regional basis, utilization ranged from highs of 100% in Europe and the Mediterranean and 94.7% in West Africa to a low of 79.8% in the Gulf of Mexico (Table 1).

Worldwide utilization of other rig types was: semisubmersibles 78.9%; drillships 75%; drill barges 80%; and inland barges 76.7%. Utilization of the worldwide offshore fleet of 644 rigs was 86% as of Dec. 6, 2004, according to Rigzone.

Most of the world's jack ups are US-owned. Transocean Inc. and TODCO control the largest fleet (52), followed by GlobalSantaFe Corp. (45), ENSCO International Inc. (42 + 2 under construction), Noble Drilling Services Inc. (41), Pride International Inc. (32 – 3 for sale), Rowan Cos. Inc. (24 + 3 under construction), Nabors Industries Ltd. (16), and Diamond Offshore Drilling Inc. (14).

Among the larger fleets of jack ups controlled by non-US companies are: China Oilfield Services Ltd. (11 + 1 under construction), Denmark's Maersk Contractors (9), National Drilling Co. of Abu Dhabi (9 + 1 under construction), India's Oil & Natural Gas Corp. (8), and Romania's Petromar Constantza (7).

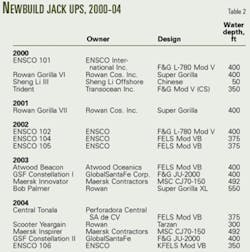

Into this tightening market, a number of drilling contractors and operators introduced 12 new jack ups from 2000-03, and 5 in 2004 (Table 2). Twelve more are under construction, scheduled for completion in 2005-06.

null

null

null

null

Rowan rigs

Houston-based Rowan Cos. Inc. is investing in more new jack ups this decade than any other company worldwide, and the company is focusing on equipment for shallow water, deep gas drilling. The company has also been planning to sell three jack ups for $40-45 million each, according to Lehman Bros. analysts, possibly in first-half 2005.

Rowan accepted delivery of the last of the big rigs, the Bob Palmer Super Gorilla Class jack up from the LeTourneau Inc. yard in Vicksburg, Miss., on Aug. 15, 2003 (Fig. 1).

The Bob Palmer hull weighs about 21,130 kips, compared with the Gorilla IV hull (last of the Gorilla Class, built in 1986), which weighs about 19,466 kips, according to the American Bureau of Shipping. The Bob Palmer deck is 306 ft long, 300 ft wide, and 36 ft deep. The Super Gorilla XL (extra leg) design features legs 578 ft and 712 ft long, with a triangular jacking system. The rig's six Caterpillar 3516B HD V 16, 4-cycle turbocharged motors can deliver a total 16,975 hp.

In September, the Bob Palmer was drilling Shell's deep shelf Joseph well in the Gulf of Mexico for $70,000/day (26,500 ft expected TD). This may be followed by a contract for the Shark Attack well, 300 days of drilling to reach a 30,000 ft TD, at potentially $100,000/day.

Next came the first of four Tarzan rigs, the Scooter Yeargain, delivered on Apr. 24, 2004 (Fig. 2). The new Tarzan Class rigs are intended for deep drilling in shallow water, with legs 411 ft and 445 ft long.

The Tarzan design is lighter weight (about 12,551 kips) and has a deck half the size (215 ft x 196 ft x 22 ft) of the Gorilla and Super Gorilla Class rigs. The Scooter Yeargain has a rack-and-pinion jacking system, with 18 pinions in each leg. According to the ABS, the rig can jack up with up to 50% preload, "making jacking operations more efficient because less time is consumed emptying and filling the tanks." The rig's jacking capacity can lift 21,600 kips without preload and 28,350 kips with preload.

The Scooter Yeargain is equipped with five Caterpillar engines that can deliver 10,750 hp, about 25% more than the 7,950-hp Gorilla design, but still less than the powerful Super Gorilla.

The construction was financed under the Title XI federal ship-financing program of the US Department of Transportation's Maritime Administration (MARAD). In February 2003, Rowan was approved for almost $181 million in financing under Title XI, for two jack ups with a total project cost of almost $207 million.1

Rowan rigs are classed by the ABS and are among the very few mobile offshore drilling vessels to work under US flag.

Maersk sister rigs

Denmark's Maersk Contractors, part of A.P. Moeller-Maersk AS, had two new ultra-harsh environment jack up rigs built on spec by Hyundai Heavy Industries Co. Ltd. in Korea. The sister rigs are both MSC CJ70-150 design, capable of working in about 500-ft water and drilling to 30,000 ft. The 46 ft x 52 ft x 210 ft derricks have a static hook load capacity of 2 million lb and have Varco TDS-8 SA top drives.

The Maersk Innovator was delivered in January 2003 and went to work in the North Sea (Fig. 3). Maersk told OGJ that the rig began a 4-year contract with ConocoPhillips Norway in fourth-quarter 2004, during which it will drill 25 wells over a new wellhead platform on the Ekofisk field.

Maersk took delivery of the Maersk Inspirer from Hyundai on July 23, 2004. The rig left the Far East at the end of October on the heavy lift vessel Mighty Servant 1 and is scheduled to arrive in the North Sea by the end of the year (Fig. 4). The rig will head to a yard in Invergordon, Scotland, before its first contract in February 2005, working for ConocoPhillips in the UK sector of the North Sea.

Maersk rigs are classed by det Norske Veritas (DNV).

Twin Constellations

Houston-based GlobalSantaFe Corp. has two new deepwater jack ups at work. The Constellation jack ups are Friede & Goldman JU 2000 design, built at the PPL Shipyard in Singapore. The 40 ft x 40 ft x 170 ft derrick provides a static hook load of 1.6 million lb, 3,000-hp drawworks, and houses a National Oilwell power swivel top drive. The 108-ft-long cantilever has a 75-ft reach (behind the transom) and 15-ft potential transverse movement (Fig. 5).

Each rig has two large deck cranes with 120-ft booms, a smaller third crane, and a knuckle boom crane mounted on the cantilever used for pipe handling.

The Deck Smart system allows triple stands of drill pipe and doubles of casing to be made up or broken out on the cantilever deck and either stored on the cantilever or transferred to the rig floor using the horizontal to vertical (HTV) pipe elevator. In the derrick, the StarRacker automates pipe-handling.

The legs are 548 ft long, set on 59-ft-diameter spud cans, allowing the rigs to work in 400-ft water. Accommodation quarters for 120 people wrap around the forward leg (Fig. 6).

Constellation I was delivered in June 2003 and is working for BP Trinidad and Tobago (BPTT) through August 2007. The rate is nearly $80,000/day.

Constellation II was delivered in March 2004 and moved to Tierra del Fuego to drill a well for Total SA off Argentina. The contract with Total commenced Oct. 16 and is expected to end July 2, 2005, at about $75,000/day.

Both Constellation jack ups were classed by ABS and operate under Vanuatu flag. GlobalSantaFe spokesperson Julie Tushingham told OGJ that the company has no plans for any future speculative building.

null

ENSCO rigs

Dallas-based ENSCO International Inc. has an active fleet renewal program. It took delivery of five newbuild jack ups from 2000-03. The ENSCO 101 and 102, both Friede & Goldman L-78- Mod V design, were completed at Keppel FELS in 2000 and 2002. Two other jack ups were built in 2002, both KFELS Mod V-B (Super B) Class design—the ENSCO 104 at FELS, Singapore, and the ENSCO 105 at AmFELS, in Brownsville.

The ENSCO 102 cost more than $95 million to build, and the rig is capable of working in water to 400 ft and drilling to 30,000 ft (Fig. 7). It was classed by ABS and operates under Liberian flag.

The company has two new jack ups under construction at Keppel FELS yard in Singapore, both KFELS Super B Class (Fig. 8). The ENSCO 106 will be commissioned mid-January 2005, according to ENSCO spokesperson Michelle Anderson.

In addition, the ENSCO 68 jack up is undergoing a conversion in the AmFELS yard in Brownsville for $28.5 million. The rig is a LeTourneau 84-S, originally built in 1976.

The company reported in July 2004 that the ENSCO 67 left the Gulf of Mexico in June for a Singapore shipyard, where it will be converted from a slot to cantilever configuration, with redelivery in second-quarter 2005. The ENSCO 88 upgrade was completed this year, and the ENSCO 95, 84, and 87 entered shipyards for upgrades in third and fourth quarters 2004.

null

null

null

Mexico

On Feb. 19, 2004, Perforadora Central SA de CV accepted delivery of a new jack up rig from the AmFELS yard in Brownsville, Tex. The Central Tonala is a KFELS Mod V-B Class design, capable of drilling in 375-ft water depths. Rigzone reported in July 2002 that the keel was laid 1 month ahead of the schedule specified in the $83-million contract signed in April 2002.

The construction was financed under MARAD's Title XI federal ship-financing program. Total cost was more than $117 million, of which almost $88 million was financed by MARAD, amortized over 15 years.2 3

The new Central Tonala jack up takes the name of another jack up rig previously owned by Perforadora Central, sold to Chiles Offshore Inc. in July 2001, and renamed the Chiles Coronado (Marathon LeTourneau Super 116 design).

The new rig joins two other jack ups managed by Perforadora Central, Central Grijalva (1980) and Central Usumacinta (1982), both mat cantilever Bethlehem JU-200 MC design, built by now-defunct Bethlehem Steel Co. The Central Grijalva was built in Beaumont, Tex., and the Central Usumacinta was built in Singapore.

The Central Tonala is the fourth KFELS B Class rig completed since 2000, and five more are under construction. The design features single-stage preload. The rig is under contract to Petroleos Mexicanos (Pemex), drilling in the Bay of Campeche.

Continuing construction

Sixteen jack up rigs are under construction currently, scheduled for delivery in 2005 and 2006. Details will appear in OGJ in January 2005.

References

1. Title XI approved applications, fiscal year 2003, http://www.marad. dot.gov/TitleXI/PDF/fy2003.pdf.

2. Title XI approved applications, fiscal year 2002, http://www.marad. dot.gov/TitleXI/PDF/fy2002.pdf.

3. Title XI highlights for 2002, http://www.marad.dot.gov/TitleXI/cus_ser_plan.html.