High-temp. MWD, LWD tools help South Texas wells

Acquiring wellbore and formation data in high-temperature South Texas wells is often limited by the ability of measurement-while-drilling (MWD) and logging-while-drilling (LWD) technology to operate in hostile wellbore environments. In two recent applications, Newfield Exploration Co. significantly improved on those operational limits when it acquired high-quality data at unprecedented temperature extremes.

Accurate real-time MWD steering was accomplished at bottomhole circulating temperatures (BHCT) that reached 363° F. (184° C.). High-quality, triple-combo LWD data were acquired at temperatures greater than 340° F. (171° C.) BHCT. In both instances, Newfield performed operations that were previously unachievable due to the limit of existing technology.

The ability to perform these operations has a far-reaching effect in area drilling operations, as well as in many other hot-hole applications. For the two wells cited in this report, high-temperature steering and logging improved well economics by:

Making a lower-cost sidetrack a viable option.

- Eliminating the need to run a liner.

- Allowing acquisition of high-quality logs through the pay zone.

- Reducing the time and risk to acquire well logs.

- Improving well-control safety and risk during logging.

On a broader scope, steering and logging at these temperatures allows challenging wells to be more effectively drilled and completed, thus reducing overall costs and enhancing the viability of development prospects.

MWD application

In Newfield's drilling operations in Duval County, Tex., the quality of the well often depends on optimal well placement within the reservoir. Dipping beds encourage deviation, which complicates steering. But bottomhole circulating temperatures in the 15,000-18,000 ft (4,572-5,486 m) wells can be greater than 350° F. (177° C.), which generally exceeds the capabilities of conventional MWD technology.

As a result, the temperature gradient has prevented precise steering below 15,000 ft.

To acquire critical azimuth and inclination data, drillers have guided previous wells with time-consuming, single-shot surveys.

To improve on the limited data acquired with these multiple single-shot surveys and reduce the time expenditure, Newfield chose to drill the Carillo Conoco Fee No. 1 well with an advanced MWD technology recently developed specifically for use in high-temperature, high-pressure wellbores.

The MWD system was developed for Precision Drilling Corp. as part of an initiative to apply a broad suite of leading-edge capabilities to the development of breakthrough technology. Its hostile-environment-logging MWD system is pressure-rated to an industry-high maximum of 30,000 psi (207 MPa).

The system's original temperature limits—already at an industry high with reliable operation up to 356° F. (180° C.) and survivability up to 392° F. (200° C.)—were easily surpassed on the Carillo Conoco Fee No. 1 well.

During 12 days of drilling, bottomhole circulating temperature reached 363° F., 7° above the MWD system's maximum operating limit.

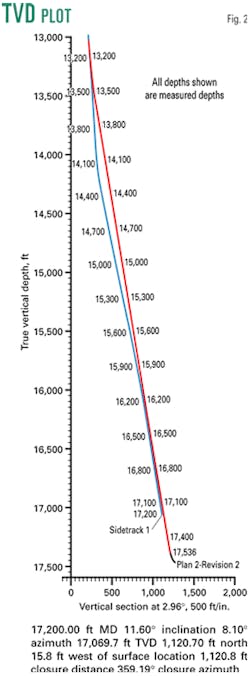

Even at these extreme temperatures, the data (directional, gamma ray, and borehole annular pressure) were very accurate. Comparative surface-readout gyro measurements were within 1° azimuth and 0.1° inclination (Fig. 2).

The reservoir section of the wellbore was placed within 20 ft of the objective.

LWD application

High temperatures were an additional complication to logging procedures on the Peach Creek No. 5 well in Wharton County Tex.

Excessive torque and drag made reaching the 16,250-ft (4,953-m) target depth with wireline tools impossible without the time and expense of conditioning the hole (Fig. 4). Well control issues, however, eliminated wireline as an option altogether.

null

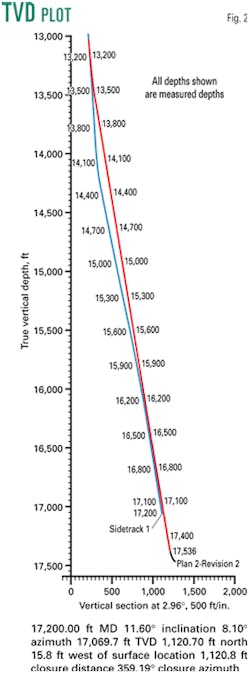

To log the well, Newfield elected to try a new hostile-environment LWD system also developed for Precision Drilling (Fig. 1).

The ability to run the system on drill pipe eliminated wireline concerns regarding wellbore restrictions and well control.

But the ability to acquire triple-combo logs in the extremely high-temperature wellbore provided a valuable option.

The LWD system operated with wireline-equivalent precision and accuracy in acquiring multifrequency resistivity, azimuthal density, and thermal neutron porosity data to 16,250 ft in 17.8 ppg oil-based mud.

Rated to operating extremes of 30,000 psi (207 MPa) and 302° F. (150° C.), the system acquired this information in bottomhole circulating temperatures that reached 347° F. (175° C.) –45° above the maximum operating limit and 18° above the survival limit.

Operational, economic advantages

The ability to acquire MWD and LWD data in these extreme conditions has significant ramifications for operational and economic aspects of Newfield's development program.

Accurate wellbore placement is critical to optimizing production from these wells. But sidetracks to exploit the reservoir fully are a costly component of the drilling operation at $1-2 million each.

This expense is related to high temperatures, which had resulted in a shallower kickoff point to stay within the operating parameters of conventional MWD systems.

The ability to steer at higher operating temperatures reduced sidetrack costs by allowing a deeper kickoff point

The ability to use MWD instead of single-shot surveys in the deeper, hotter sections of the hole significantly reduced hole tortuosity by allowing much quicker response to more frequent steering information (Fig. 3).

Although time-consuming, single-shot surveys had been taken every 100-200 ft, MWD surveys were taken every 60-90 ft.

Because the wellbore was smoother, torque and drag were significantly reduced while drilling.

Torque was about 4,000-5,000 ft/lb—about half of what had been experienced in offsets.

Pickup and slack-off weights were also significantly reduced to about 10,000-20,000 lb vs. 30,000-40,000 lb in a direct offset.

This reduction in weight and torque allowed casing to be run to total depth, which eliminated the need to run a liner that had been planned. The resulting cost reduction was about $400,000/ well.

Greater accuracy in sidetracking and improved hole quality made sidetracking this well economically feasible. Previous attempts with similar well plans were not able to achieve the necessary accuracy and consequently resulted in more tortuous paths.

The option in such cases was to drill a new well. The ability to sidetrack this hot hole saved $1.2 million vs. drilling a new well which would have otherwise been required.

On the Peach Creek No. 5 well, the ability to run high-temperature logging tools on drillpipe allowed acquisition of high quality, triple-combo logs.

To address excessive torque and drag issues, the wireline alternative has traditionally been to spend several days conditioning and opening the hole.

But with well control also an issue, the remaining option was to run the liner and log in cased hole, which would have provided even less descriptive data.

In the lower section of the Peach Creek No. 5 well, excessive torque and drag prevented wireline logging as called for in the well prognosis.

The triple-combo LWD system recorded accurate formation data to wireline-equivalent precision.

The wireline-quality data acquired with the LWD system provide a significant advantage in understanding the productive interval and designing a more effective completion.

Elimination of wireline-associated well control conditions benefited risk mitigation and wellsite safety. And the ability to log without conditioning the hole offers further time and cost reductions on future wells.

Bruce Darlington ([email protected]) is a drilling engineer at Newfield Exploration Co., Houston. He previously worked for Anadarko Petroleum Corp. Darlington holds a BS in petroleum engineering from Colorado School of Mines. He is a member of SPE.

Tom Hicks ([email protected]) is an account manager at Precision Drilling Services, a division of Computalog USA Inc., Houston. He has more than 25 years of experience in the oil field service industry. Hicks holds a BA in business. He is a member of SPE and SPWLA.