SPECIAL REPORT: Gulf of Mexico King field gets world’s deepest subsea pumps

In July, BP America Inc. began installing two subsea pump stations to boost production from three wells in King field, Gulf of Mexico. At 1,700 m, this is the world’s deepest installation of subsea multiphase pumps.

The electric pumps will be powered by a Nexans umbilical from the Marlin tension leg platform in Viosca Knoll Block 915, 18 miles away.

MultiBooster pumps

Aker Kvaerner says the MultiBooster subsea pump technology was developed under the Norwegian government’s Demo 2000 program, with support from major oil companies. Cost of the development from 1998-2005 was about 100-150 million kroner ($17.5-26.3 million).

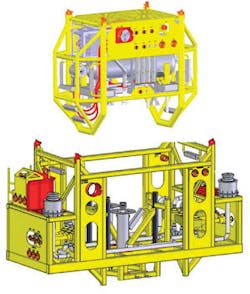

In October 2005, Aker Kvaerner announced an engineering, procurement, and construction contract with BP for the subsea pumping project, worth 220 million kroner ($38.6 million). Aker Kvaerner is providing modules with manifolds, variable speed drives, topside and subsea control systems, a topside lube oil hydraulic power unit, and high voltage connectors and jumpers to BP for two operating pump stations and one spare. The equipment was manufactured at Aker Kvaerner Subsea’s facility in Tranby, Norway (Fig. 1).

MultiBooster technology was recognized at the 2006 Offshore Technology Conference with a Spotlight on Technology award (OGJ, May 8, 2006, p. 25). The MultiBooster with Bornemann twin-screw multiphase pump inserts will increase oil recovery and enable longer step-out distances between wells and tieback facilities by adding energy to the wellstream, increasing flowline pressure, and improving recovery. The modular design should facilitate installation and removal (Fig. 2).

null

Lyell field

Aker Kvaerner ran a MultiBooster system pilot off Scotland in the North Sea. In May 2005, Canadian Natural Resources International requested a MultiBooster pump system for the Lyell field.

Aker Kvaerner delivered the 50-tonne pump module to CNR in December 2005 and installed it in 145-m water depth. The system is powered by an umbilical from the Ninian North platform, and the Lyell production flowline connects to the Ninian South platform.

King field

BP’s objectives for its deepwater Gulf of Mexico subsea pump project are to:

- Develop cutting edge technology that increases recovery from existing fields.

- Prove up technology for subsea pumping.

- Share technology across the Gulf of Mexico and worldwide.

King field is in water depths of 4,900-5,600 ft in Mississippi Canyon Blocks 84, 85, 128, and 129. BP is the sole equity owner with 100%.

BP’s Nicola Montorsi told OGJ the key technology challenges at King were the high-voltage umbilicals and connectors (12,000 v), pump seals, and remote operations of the subsea kit. Inlet pressures at King range 48-127 bar.

Aker Kvaerner shipped three MPC-335-50s Bornemann pumps from Norway in June. Each weighs about 57 tonnes. They can reach up to 50-bar differential pressure. Each pump station weighs 70 tonnes.

Montorsi said the pumps arrived in Mobile, Ala., early July, installation began in mid-July, and the full project would require 10-12 weeks. BP expects the pumps to be operating by yearend.

Each of the pumps at King field is designed to handle as much as 75,000 b/d. Each is rated to 5,000 psi and will handle reservoir fluids at 60° C.

Three wells will be boosted from two pump stations: one MultiBooster will work on the D5 (King) and D3 (King West) wells; the other will work on well D6 (King).

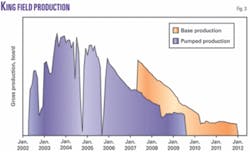

King field production began declining sharply at the end of 2005, but BP expects addition of subsea pumps to extend meaningful production into 2012 (Fig. 3).

null