Polymer flooding can increase Orinoco Belt recovery

Chuck Norman

Andes OFS SRL

Buenos Aires

The Orinoco Belt in eastern Venezuela extends across 55,000 sq km and holds about 90% of the world’s proven heavy and extra-heavy oil reserves. It is, however, the world’s least developed oil deposit of its type and magnitude.

The exodus of most international oil companies, budgetary constraints at Venezuela’s state oil company Petróleos de Venezuela SA (PDVSA), shortage of qualified technical personnel, and environmental impact concerns have conspired against oil and gas development in Venezuela. Most of the US government sanctions that began in 2014 remain in place. Recent diplomatic overtures, however, may reopen foreign investment in Venezuela.

Polymer flooding can access untapped oil reserves in heavy oil reservoirs such as the Orinoco Belt. Pelican Lake in Canada provides a suitable analog for Orinoco due to similar depositional environments and petrophysical characteristics. Polymer flooding in Pelican Lake has been continuous since 2004 and successful in increasing recovery.

There are no technical or economic barriers to applying polymer flooding in thick Orinoco Belt reservoirs, and the cumulative and consistent success of polymer flooding in Pelican Lake provides a model for Orinoco enhanced recovery.

Orinoco Belt

The Orinoco Belt geologic anomaly occupies the southern strip of eastern Orinoco River basin and divides into four exploration and production areas: Boyacá, Junín, Ayacucho, and Carabobo (Fig. 1). The United States Geological Survey estimates Orinoco Belt original oil in place (OOIP) between 900 billion and 1.4 trillion bbl.1 Reservoir studies by PDVSA fall in the same range (OGJ, Feb. 7, 2010).2

The discovery well, La Canoa 1, was drilled in 1935 with reported production of 40 bo/d with 7° API gravity. Orinoco activity was limited until 1978 when PDVSA began a 5-year drilling program that included about 650 wells. Several technologies to produce the extra heavy crude were evaluated, including emulsions, in-situ combustion, steam injection, and polymer flooding. However, further investment in the Orinoco Belt has been postponed for decades in favor of lighter crudes in western Venezuela.

Geology

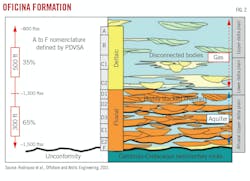

More than 90% of Orinoco Belt sediments were deposited during the Miocene epoch of the Tertiary period. Three primary Tertiary transgressive-regressive cycles have been identified, characterized by an interaction of continental and marine depositional environments (Fig. 2). Orinoco Belt hydrocarbons occur primarily in clastic sediments. The productive reservoir is the Oficina formation, a stratigraphic trap consisting primarily of fluvial and deltaic depositional environments.3 4

During primary production, crude oil mobilizes by reservoir energy, which includes rock and fluid expansion, gravity drainage, and, in some cases, an active aquifer. Waterflooding is typically implemented when initial reservoir energy is depleted.

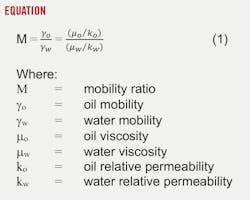

Two primary forces, viscous and capillary, govern two-phase flow in porous media during waterflooding. The mobility ratio (M) describes the relative flow of oil to water in porous media due to these forces (Equation 1). In heavy oil reservoirs, viscous forces dominate. It is not necessary or even advisable to target a mobility ratio of unity.

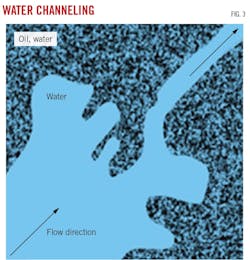

Orinoco crude viscosities range from 2,000 – 8,000 cp at reservoir conditions, and water viscosity is about 1.0 cp at 20° C. When the viscosity of the displacing fluid (typically water) is less than the viscosity of the displaced fluid, an unstable flood-front interface produces viscous fingering, characterized by random, uneven flow and rapid breakthrough of the displacing fluid at producing wells (Fig. 3). Fingering bypasses oil saturated rock. When high water-saturation channels are established between injection wells and producing wells, areal sweep efficiency decreases dramatically.

Increasing injection fluid (water) viscosity reduces the mobility ratio beyond the wellbore. Optimizing the mobility ratio at the inception of water injection prolongs water channeling and significantly improves areal sweep efficiency.

Polymer flooding

Polymers have been an effective agent to increase water viscosity dating to the 1960’s. Increasing water viscosity will reduce the mobility ratio, improving volumetric sweep efficiency of the enhanced waterflood. Polymer flooding accelerates the ultimate oil recovery that would be realized in a waterflood and, therefore, the NPV of future oil revenues. Two types of polymers have been utilized in oilfield applications: partially hydrolyzed polyacrylamide (HPAM) and biopolymers. Biopolymers have been tested in small-scale oilfield pilots, however HPAM’s are most chosen for EOR applications due to technical and economic advantages.

Orinoco Belt polymer flooding evaluations in multi-Darcy sand packs were reported in 2013 using representative lithology, reservoir brine with 7,169 total dissolved solids (TDS), injection water with 360 TDS, and dead 8.8° API gravity oil with 13,466 cp viscosity.5 The polymer solution utilized an HPAM manufactured by SNF Floerger at polymer concentrations of 2,000-3,000 ppm. Injection rates were 0.15 and 0.30 cu cm/min, and oil recoveries were 40%–57% at 46° C.

Laboratory tests reported in 2020 evaluated the impact of low-salinity injection water on polymer performance. Two sand packs were prepared using 8.7° API live oil (gas-oil ratio of 90 scf/bbl) with 2,000-cp viscosity at 54° C. Solutions with polymer concentrations of 1,000 ppm were prepared with water containing 160 and 1,035 ppm TDS. Resultant oil recoveries were 76% and 58%, respectively.6

A polymer flood field pilot with three horizontal injectors in Petrocedeño field of Junín block was also reported in 2020. Pilot objectives were to observe pressure behavior and injectivity during polymer injection and identify zones taking and bypassing the polymer solution. The evaluation documented a seven-fold improvement in mobility ratio. No injectivity issues were reported.

Pelican Lake analog

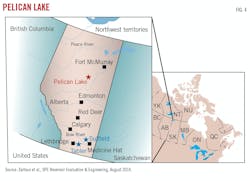

Discovered in 1978, Pelican Lake field (also known as Brintnell) in northern Alberta, Canada, covers an area of about 1,800 sq km (Fig. 4). Pelican Lake is part of the extensive Wabasca oil sands and contains an estimated 6.4-billion bbl OOIP.7 Fluid expansion provides primary reservoir energy, but the average solution gas-ratio is low (22–34 scf/Bo) resulting in primary recovery of only 5-10% OOIP.8 Table 1 shows comparisons between Pelican Lake and Orinoco Belt reservoir properties.9 10

The field included only vertical wells until the late 1980’s. Subsequently, long horizontal wells, sometimes with multilaterals, marked a major change in development strategy. Waterflooding in the early 2000’s produced low sweep efficiency due to an adverse mobility ratio.

Pelican Lake geology

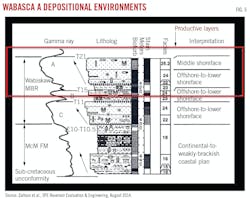

The primary productive reservoir is the Lower Cretaceous Wabasca “A” layer.11 The Wabasca formation marine-blanket sand coarsens upward from fine-grained sands and shales at the base to massive fine-grained sands at the top (Fig. 5). The unconsolidated formation contains primarily quartz and chert. For purposes of enhanced oil recovery evaluation, the petrophysics of the Canadian heavy and extra heavy reservoirs are analogous to those in Orinoco Belt, though Canadian reservoirs are dispersed over a wider area and exhibit more variation in depth, stratigraphy, and lithology.

Pelican Lake polymer pilots

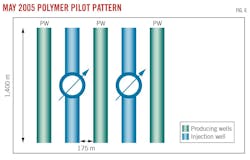

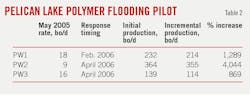

The initial Pelican Lake polymer pilot was implemented in July 1997 and included three 1,200-m horizontal wells and two producing wells. That pilot was inconclusive due to several operational problems. A pilot implemented by a new operator in May 2005 included five 1,400-m long horizontal wells. Well-spacing in that pilot was 175 m (Fig. 6). Initial results in Table 2 show significant increases in oil production.

The 17-fold increase from the May 2005 pilot led to rapid expansion of polymer flooding within the field, including multilateral injectors. Since 2007, polymer injection has followed immediately after primary production. After a decade of polymer flooding in Pelican Lake, recovery factors of 25% OOIP have been reported in 90 representative patterns with an average 0.6 pore-volume (PV) polymer injected, compared with 5-10% OOIP primary recovery. As of early 2021, Pelican Lake had more than 800 polymer injection wells and over 1,400 offset producing wells.

Table 3 shows estimated ultimate recovery factors (RF) for polymer-flooded areas in Pelican Lake as of early 2020.12 Primary recovery factors are 3-6%. Ultimate recoveries with polymer injection range from 15-38% of OOIP.

Orinoco polymer flood

Injection water quality has immediate and significant impact on the economic and technical success of a polymer flood. Several water quality variables must be considered before implementation of a polymer flood, including, but not limited to:

- Multivalent cations (hardness), primarily calcium and magnesium.

- Salinity and TDS.

- Produced species such as iron and hydrogen sulfide.

- Water treatment chemicals such as biocides and corrosion inhibitors.

In the presence of Mg+2 and Ca+2 ions in hard water, repulsive forces on the HPAM carboxylate groups are compromised. The hydrodynamic radius of the polymer chain shrinks, resulting in a loss of polymer viscosity. Water softening costs are significant but reduce the volume of polymer required to reach target viscosity and, accordingly, chemical cost per incremental barrel of oil recovery. The water strategy in a polymer flood balances water treatment and polymer costs. Based on Rodriguez et al. water analysis, connate water and injection water in Orinoco Belt are nearly ideal for polymer hydration.

Polymer injection decreases injectivity due to the viscosity of the polymer solution, adsorption on reservoir rock, and, although overlooked, impurities in the polymer solution. Injection water analyses do not typically disclose concentrations of species such as iron and oil carryover, which can vary significantly over short time periods based on the operational efficiency of water treatment. The presence of most impurities may not significantly impact waterflood injectivity but can dramatically reduce injectivity of hydrated polymer. Water samples taken directly from the water treatment plant are recommended to optimize injectivity and confirm that polymer viscosity meets target specifications.

Reservoir heterogeneity

In addition to a more favorable mobility ratio, polymer improves volumetric sweep efficiency. Polymer adsorption increases the pressure in high-permeability zones, thereby diverting injection fluid flow into lower-permeability zones. In mature waterfloods, highly water-saturated channels between injectors and producers are frequently established before polymer injection is implemented. This is particularly true in unconsolidated sands found in Pelican Lake and the Orinoco Belt with single-phase permeability measured in Darcies.

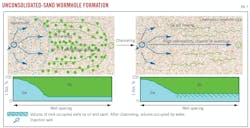

High single-phase permeability combined with an elevated Dykstra-Parsons coefficient accelerates injection fluid breakthrough. In Pelican Lake, producing wells exhibited polymer breakthrough after only 0.05 PV of polymer injection. In unconsolidated sands, these conduits connecting injection and producing wells are referred to as wormholes (Fig. 7). Chemical breakthrough at producing wells results in difficult-to-break emulsions, damage to surface production and separation facilities, and added environmental costs.

Profile modification by injecting an aqueous gelant composed of an acrylamide polymer crosslinked with a Cr+3 carboxylate-complex crosslinking agent has proven effective in wormhole mitigation. This chemistry, developed by Marathon Oil Corp., delays gelation, resulting in injection at viscosities like those of uncrosslinked polymer.13 The gelant becomes immobile with time and temperature, and blocks or partially blocks wormholes.

Before field application, gel formulations are optimized in the lab under reservoir conditions. Gel treatments almost always include several stages of varying gel strengths; polymer concentrations can be as high as 25,000 ppm. When properly designed, gel treatments have significantly reduced wormhole channeling in unconsolidated sands.14

The author

Chuck Norman ([email protected]) is president of Andes OFS, with offices in Buenos Aires, Argentina, and Denver, Colo. He holds a BS (1975) from the University of Colorado in accounting, and an MS (1989) in mineral economics and BS (1998) in petroleum engineering from the Colorado School of Mines.

References

- United States Geological Survey, “An Estimate of Recoverable Heavy Oil Resources of the Orinoco Oil Belt, Venezuela,” Fact Sheet 2009-3028, 2009.

- Layrisse, I., “Heavy Oil Production in Venezuela: Historical Recap and Scenarios for Next Century,” SPE 53464, SPE International Symposium on Oilfield Chemistry, Houston, Tex., Feb. 16, 1999.

- Isea, A., “Geological Synthesis of the Orinoco Oil Belt, Eastern Venezuela,” Journal of Petroleum Geology, Vol. 10, No. 2, April 1987, pp. 135-148.

- Rodríquez, W., Buatois, L., Mángano, M., and Solorzano, E., “Sedimentology, ichnology, and sequence stratigraphy of the Miocene Oficina Formation, Junín and Boyacá areas, Orinoco Belt, Eastern Venezuela Basin,” Marine and Petroleum Geology, Vol. 92, 2018, p. 213-233.

- Rodriquez, F., “Review of Chemical EOR Projects in Venezuela: From Light To Extra-Heavy Oil Reservoirs,” OMAE2021-63529, Proceedings of the ASME 40th International Conference on Ocean, Offshore and Arctic Engineering, virtual, June 21-31, 2021.

- Hernandez, E., Valero, E. Rodriquez, I., Guerra, E., Espinosa, J., Briceño, R., and Veliz, A., “Enhancing the Recovery of an Extra Heavy Oil Reservoir by Using Low Salinity Polymer Flooding,” SPE 190014-MS, SPE Latin American and Caribbean Petroleum Engineering Conference, virtual, July 27-31, 2020.

- Delamaide, E., “Pelican Lake: Learning from the Largest Polymer Flood Expansion in a Heavy Oil Field, SPE 208011-MS, Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, Nov. 15-18, 2021.

- Zaitoun, A., Delamaide, E., Renard, G., and Tabary, R., “Pelican Lake Polymer Flood—First Successful Application in a Heavy Oil Reservoir,” SPE Reservoir Evaluation & Engineering, Vol. 17, No. 3, Aug. 4, 2014, pp. 340-354.

- Tabary, R., Renard, G., Dwyer, P., and Delamaide, E., “Field Scale Polymer Flooding of Heavy Oil: The Pelican Lake Story,” WPC-21-0851, 21st World Petroleum Congress, Moscow, Russia, June 15-19, 2014.

- Vellarroel, T. and Hernandez, R., “Technological Developments for Enhancing Extra Heavy Oil Productivity in Fields of the Faja Petrolifera del Orinoco (FPO), Venezuela,” Article #20205, AAPG Annual Convention and Exhibition, Pittsburgh, Pa., May 19-22, 2013.

- Bazin, B., Rousseau, D., and Delamaide, E., “Chemical EOR for Heavy Oil: The Canadian Experience,” SPE-169715-MS, SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, Mar. 31-Apr. 2, 2014.

- Canadian Natural Resources Ltd., Annual Performance Presentation, In Situ Oil Sands Schemes, March 2020.

- Sydansk, R. and Southwell, G., “More than 12 Years of Experience with a Successful Conformance-Control Polymer Gel Technology,” SPE 49315, SPE Annual Technical Conference and Exhibition, New Orleans, La., Sept. 27-30, 1998.

- Saez, M., Paponi, H., Cabrera, F., Muniz, G., Romero, J., and Norman, C., “Improving Volumetric Sweep Efficiency in an Unconsolidated Sandstone Reservoir with Sequential Injection of Polymer Gels,” SPE-150492-MS, SPE Improved Oil Recovery Symposium, Tulsa, Okla., April 14-18, 2012.