Pilot projects reduce frac hits in Vaca Muerta formation

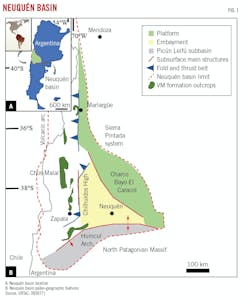

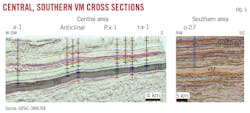

The Vaca Muerta (VM) formation is the main source rock and one of the largest areal stratigraphic units in Neuquén basin, Argentina (Fig. 1). To evaluate exploitation of the basin, Phoenix Global Resources LLC identified and ranked three assets for development. Of the three, two were deemed non-commercial, but the third warranted further exploration. Pilot studies delineated optimum locations for wells in this area without frac hits.

Pan American Energy LLC has been actively exploiting VM with infill drilling and has experienced substandard child-well performance. A pilot program improved child-well recovery by pressurizing the parent well during child-well stimulation.

VM asset evaluation

VM consists mostly of organic-rich shales alternating between mudstones, marls, limestones, volcaniclastic deposits, and other minor diagenetic elements originally deposited in a deepwater environment. Shales migrate upward in the Quintuco-VM depositional system. The formation trends to calcareous sandstones on the western and middle sections of the basin and towards limestones to the east in a shelf. VM depositional depths are less than 300 m and extend about 90,000 sq km, of which 30,000 sq km are prospective for unconventional exploitation.

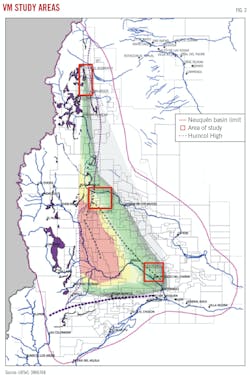

Wells completed in VM shales need to be hydraulically fractured. To evaluate such exploitation opportunities, Phoenix Global Resources identified three assets in the basin along a 420-km northwest–to–southeast path through the oil window comprising different geological settings (Fig. 2).

The northern exploration area contains the Malargüe´s fold and thrust belt in Mendoza province. It is structurally complex and contains several vertical wells. The middle block, in the northwestern sector of Neuquén province bounded by the Huantraico syncline to the south, the Chos Malal fold and thrust belt to the west, and the platform to the north–northeast, comprises mudstone facies intruded by magmatic sills. It contains several vertical and horizontal standalone wells which have provided completion information, fracture design analysis, sill interpretation, water and gas isotopic characterization, wettability, and geochemical analyses.

The third asset, south near Neuquén city, is in the appraisal stage and lies in neither volcanically active nor structurally complex areas. The Cocina southern target area is thicker in this region compared with the rest of the basin, and studies on horizontal wells in this area included well spacing strategies, completion designs, landing point selection, vertical stacking, and drawdown strategy.

Phoenix’s review identified key parameters to determine commerciality for unconventional development in the assets. Geochemistry, petrophysics, cuttings, sidewall cores, electric logs, 3D seismic, surface microseismic, pressure gauges, PVT, and isotopic characterization for gas and water were all analyzed from published information to de-risk acreage for progression from exploration to development. Key variables to determine unconventional development feasibility include:

- Depositional environment.

- Formation mineralogy, especially clay content.

- Total organic content (TOC).

- Formation depth and extension.

- Formation continuity and structural complexity.

- Gross and net thickness.

- Thermal maturity.

- Pore pressure.

- Reservoir porosity.

- Reservoir saturation.

VM formation

VM formation comprises generally less than 30 wt % clay content. Optimum clay content for successful unconventional production is about 30-40 wt %. For assets in this study, clay content averaged between 15-40 wt % with less than 20 wt % average across each area.

TOC averages 8 wt % in the north of Neuquén province, and values decrease to less than 1 wt % towards the proximal environment of the system. Maximum TOC is 12-13 wt % while the basin contains an average 3 wt % TOC. Cut-off for economic hydrocarbon recovery is greater than 2 wt %. Hydrogen index (HI) in the northern area is high (> 600 mg hydrocarbon content (HC)/g), indicating early thermal maturity with limited amounts of kerogen converted to hydrocarbons. In the central and southern areas, HI ranges from 10-400 mg HC/g and suggests positive source rock potential containing Type II-III kerogen.

Thermal maturity as measured by vitrinite reflectance (Ro) in the northern area lies between 0.55 and 0.7%, indicating marginal-to-early maturity hydrocarbon generation and black oil with API density of 20-25° API. Ro must be above 0.8% to generate mature hydrocarbons and organic pores.

For the central area, Ro ranges from 0.9-15.0%, suggesting different oil types based on formation thickness and burial evolution. Oil densities are 40-53° API. The southernmost area has Ro values close to 1%, indicating an early oil window, 32-38° API oil density (Fig. 3), and 0.6-1 cp viscosity. These parameters suggest better preferential flow through pores and fractures relative to the northern area.

The northern block formation depth is 1,200-3,900 m over only 4 km in distance due to restrictions from the Malargüe fold and thrust belt. VM shale is the detachment interval in this region. In the central area, base formation depth ranges between 2,100 and 4,200 m but varies over a longer interval (35 km) without detachment in the shales. The formation in the southern area lies between 3,100 and 3,150 m and varies over a 17-km range with low regional slope.

Pore pressure obtained from diagnostic fracture injection tests (DFIT) in the VM formation is not always reliable due to extensive test time required to reach radial flow. Estimated pore pressures of 0.75 psi/ft and 0.9 psi/ft in central and southern assets, respectively, indicate that wells can flow without artificial lift. The shallow end of the northern area, by contrast, contains low pressure gradients (< 0.6 psi/ft) and cannot flow on its own.

The northern area has an average 150-m net thickness. The central area’s net thickness varies from 200-500 m from northeast to southeast and the southern area’s thickness varies from 60-120 m trending northwest to southeast. These net thicknesses all exceed the US Energy Information Administration’s (EIA) recommended 40-50 m net thickness with TOC above 2 wt % for economic unconventional development.

The northern area has 6% average porosity due to lower thermal maturity of the source rock (early oil window). Water saturation is 10-30%. The central and southern areas show about 12% average porosity values with both organic and inorganic pores. For the central area, water saturation (Sw) averages about 50% in the zone of interest. Water saturation in the southern area is 20-30%.

Asset structures

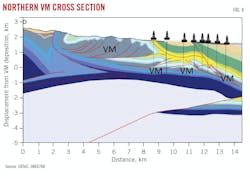

The northern area contains complex structures in the fold and thrust belt created through multiple events and processes. The most recent event uplifted the area and created the Malargüe Anticline, reducing rock permeability, increasing natural fractures, and disrupting continuity. Surface rock exposure allows circulation of meteoric water and subsequent alterations in traps, seals, and hydrocarbon migration. Extended faulting and folding created a discontinuous reservoir which is disadvantaged towards large-scale horizontal well-grid development (Fig. 4).

In the central block, only a few minor inverse faults and some local anticlinal folds affect the base of the VM formation. The southern region likewise contains low structural complexity with fault discontinuities affecting only underlying VM formations and ending towards its base without affecting the VM formation’s potential as an unconventional shale-type reservoir in this region (Fig. 5).

A strike-slip regime generally exists in the VM where the minimum horizontal stress (sh) is close to vertical stress (sv). An inverse regime, where the maximum horizontal stress (sH) is greater than the vertical stress (svVM unconventional development potential.

Table 1 lists the main variables for successful unconventional VM development. Cutoffs indicate minimum requirements for each variable. Variables highlighted in red are below cutoffs.

In the northern area, low pore pressure, low API density, low porosity, high viscosity, and high geological complexity over a small areal extent limit opportunities for exploitation. The southern area, by contrast, has good reservoir pressure, good fluid properties, and little structural faulting which aids in geosteering and hydraulic fracturing. These properties make this area the most favorable for development. Based on these analyses, only the southern area was selected for further exploration and development.

Southern VM well studies

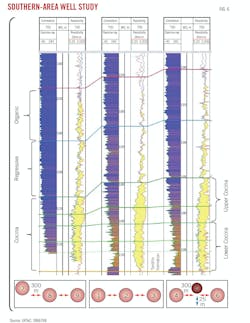

An 80-100 m organic rich VM seam provided the basis for a well placement study. Three locations were drilled and completed with three horizontal wells in each pad, targeting upper and lower Cocina (a stratigraphic column of VM mudstones deposited on top of Tordillo formation standstones) with 300-m spacing between each well (Fig. 6). In Location A (center), Wells #1, #2, and #3 were drilled in the same interval. In Location B (right), Wells #4 and #5 were at the same depth with central Well #6 landed 25 m above the other wells, testing the uppermost landing zone. In Location C (left), Wells #8 and #9 were at the same depth, with leftmost Well #7 landing 7 m above the other wells.

Stimulation for all wells used 2,600 lb/ft of 100-mesh sand pumped at 50 bbl/min with 70-m stage separation and 10 clusters/stage in zipper fracturing mode. Stimulation fluid included oil and water tracers. Pad A acquired microseismic data while executing Frac Stages 10-35 of each monitored well. Gauges monitored wellhead pressure (WHP) during stimulation, and bottom-hole memory gauges placed before production recorded pressure with time-deferred sequences. Gauges were removed and interrogated after 1 and 6 months.

Fig. 7 shows intrapad well interferences based on pressure and tracer data. Circled outlines represent fracture stages. Red circles identify frac hits, green circles represent no hits, and white circles denote lost data due to operational sequencing. For Pad A, hits were strong when it was put on production, but interwell connections dropped after 6 months. Microseismic confirmed this interpretation. Pad C showed only weak-to-moderate interference during initial production. Pad B showed no frac hits during the first 3 months of production. The interference after 6 months of production had not been checked in time for publication.

A 300-m well-spacing, with wells all in the same landing plane, resulted in well connections during the first 6 months of production. By contrast, wells staggered 5-25 m out-of-plane showed weak or no connections. The study concluded that staggered landing zones minimize early frac hits in this area of the VM formation.

Pan American study

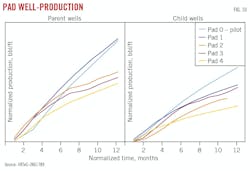

In general, child wells tend to have lower productivity per stimulated foot and recover only a portion of parent-well normalized reserves. Pan American Energy performed parent-child interaction studies to limit child-well production decline in the oil window in the VM.

To minimize parent-child interactions, Pan American performed a pilot which pressurized parent wells per a US unconventional technique in areas of low well spacing before completing child wells. Oil tracers in parent and child wells and wellhead pressure gauges monitored interwell interactions during pressurization and fracturing.

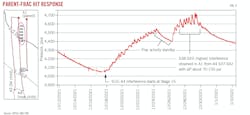

Fig. 8 shows the parent-well location with respect to child wells. A1-parent lateral length is 6,562 ft, and it has 27 equally spaced stages (geometric stage placement) with 245-ft stage-spacing. Total proppant pumped during fracture stimulation was 16 million lb using 283,000 bbl of water. Recovered water was 30% of injected water.

A1 produced for 27 months until it was shut in for fracture stimulation on child wells A3 (far) and A4 (near). A4 is 722 ft from A1. All three wells have the same landing point target, and all were geosteered toe down.

A total of 314,000 bbl of water injected into A1 before completing the child wells represented about 70% of the estimated theoretical volume required for full pressurization. This volume, however, was deemed sufficient for a pilot project. Water was pumped for about 5 days below fracture pressure at about 40 bbl/min. Instantaneous shut-in pressures (ISIP) were recorded every 62,800 bbl. ISIP’s increased from 4,250 psi at the beginning of the job to about 4,500 psi at the end.

Child wells were completed with engineered perforation and variable stage placement based on log-derived unconfined compressive stress measurements, in contrast to the parent’s rigid geometric stage placement. The former approach maximizes frac-stage spacing by stimulating only rock with similar geomechanical parameters and avoids perforation clusters in possible depleted zones. Table 2 shows stimulation parameters for child wells.

Fig. 9 shows A1 WHP during A3 and A4 fracturing. Interference started on A4’s Stage 15 which was at the toe of the parent and about a third from the bottom of A4. Interference continued and maximized at stages near the heel of A1, indicating that near-heel A1 stages were the most depleted.

Tracer analysis after flowing back all three wells showed that all stages in child wells contributed oil and water. The heels produced an average stage amount of total fluid but flowed back little oil vs. water. This effect was attributed to the parent well’s heel stage depletion. Only slight connectivity was observed between A3 and A4 Frac Stages 10, 11, and 12 due to less than 2% of tracers injected in these stages being recovered in A3. There was practically no connectivity from A3 to A4 because only about 1% of the oil tracers injected in A3 well stages were recovered in A4.

The results showed that stimulated fractures between A4 and A3 were not highly connected and the selected well spacing was appropriate for pad development.

Comparing post-completion results between the pilot pad using a pressurized parent and other pads without pressurizing the parent showed that increasing distance between wells (3,281 ft) without pressurizing the parent may have had minimum risk for fracture hits but resulted in child wells with lower productivity than the parent and yielded lower reserves (Table 3). Pad 1 child wells had about 50% less cumulative oil production than the parent.

Based on “Geological Characterization of Vaca Muerta Fm. Through Virtual Outcrops Technology, Neuquén basin, Argentina,” URTeC: 3839771, “Assessing the Potential of Three Assets: From Exploration to Development, a Multidisciplinary Integration Case,” URTeC: 3866768, and “First Operator’s Tested Strategies in Vaca Muerta to Prevent EUR Degradation by Parent Child Effects,” URTeC: 3861789, presented at the Unconventional Resources Technology Conference, Denver, Colo., June 13-15, 2023.

About the Author

Alex Procyk

Upstream Editor

Alex Procyk is Upstream Editor at Oil & Gas Journal. He has also served as a principal technical professional at Halliburton and as a completion engineer at ConocoPhillips. He holds a BS in chemistry (1987) from Kent State University and a PhD in chemistry (1992) from Carnegie Mellon University. He is a member of the Society of Petroleum Engineers (SPE).