Acoustic waves improve oil recovery in Permian basin

John Benton

Hydroacoustics Inc.

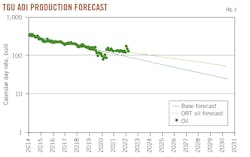

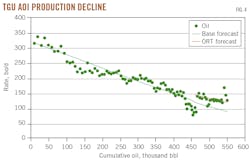

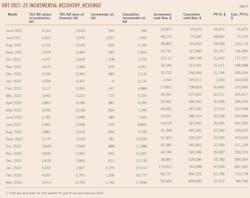

Henrietta, NY

Hydroacoustics Inc. (HAI) installed a single oil recovery tool (ORT) in the Permian basin’s Turner Gregory Unit #912W injection well (TGU 912W) to improve recovery. The device began full 24-hour operations in May 2021 and a quantifiable response was identified beginning June 2021. The ORT reduced the decline rate within the area of interest (AOI) of the device to 9.5% from the area’s historic 14.5%, generating a more than 30% increase in production and adding more than 100,000 bbl of estimated recoverable reserves for a 10-year period. The ORT increased the AOI’s cash flow by about $500,000/yr resulting in a cumulative $3.8 million PV10 over the 10-year period, considering operating expenses and discount factor.

ORT

ORT recovers additional oil from mature reservoirs through low-frequency vibration energy from a downhole source (OGJ, Apr. 18, 2005; OGJ, Aug. 1, 2016). Acoustic energy is emitted from a transducer in the form of pulsed pressure waves that pass through liquid hydrocarbons in the formation. This application, at source frequencies generally less than 1 khz, is called sonic, acoustic, seismic, p-wave, or elastic-wave well stimulation. Explanation for the mechanism of vibrational energy recovery vary, although in general, vibrational energy dislodges oil droplets and reduces capillary forces by altering surface and interfacial tensions in the formation to coalesce and recombine into a continuous oil phase. Degassing and oil-water separation during vibrational excitation also improve recovery factors.

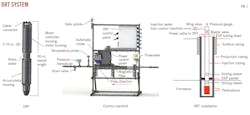

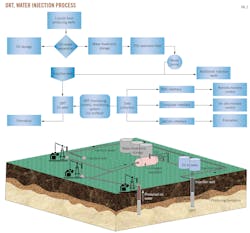

HAI’s ORT consists of two primary components: the downhole device and a monitoring and control system at surface. The device requires a power cable in the well to connect it to the control panel and feed power to the downhole motor. A supply of filtered water is required to generate pulsed pressure waves. The control system at surface is used to convert field AC power to clean 57 volts DC, manage the flow rate into the well, start and stop the device, manage the device’s operating frequency, and record pressure, temperature, and flow rate. An optional solar-battery system can be used if field AC power is not available.

The downhole device, about 3 ft long and 3.75 in. in diameter, comprises three major components: a permanent-magnet motor, rotary valve, and an accumulator. The motor spins the rotary valve at a set rpm to generate acoustic pulses at 40 hz. The accumulator acts to shape and amplify the pulse. Fig. 1 provides diagrams of the ORT, the surface control system, and a simplified wellbore diagram. Fig. 2 shows a process flow diagram and simplified field-installation schematic.

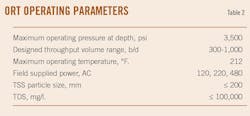

The feedstock for the ORT is produced water with total dissolved solids of less than or equal to 100,000 mg/l. and total suspended solids filtered to 200 mm or less in size. Feedstock volumes can range from 300-1,000 b/d (48-160 cu m/d). The ORT produces about 2 kw of power when operating at 600 b/d. The ORT preferred operating range is 600-800 b/d. It has a 1-mile radius effective range from the point of installation and can be utilized in any producing oilfield less than 7,500 ft deep with a producing gas-liquid ratio (GLR) of less than 2,000 std cu ft/bbl and API oil gravity ≥ 20°.

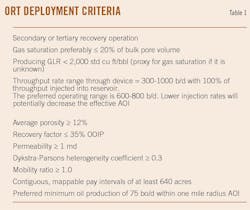

Reservoir type

The technology will work in clastic or carbonate reservoirs and consolidated or unconsolidated sands. The effective range of the ORT may be decreased in unconsolidated reservoirs, although parameters such as porosity, permeability, and heterogeneity likely have a larger impact on its effective range. Table 1 lists guideline criteria that represent the basic deployment for an application of the current design. Locations that do not completely fit within these guidelines can also be considered and evaluated. Table 2 lists the current operating parameters of the ORT.

TGU application

HAI installed a single ORT in the TGU 912W injection well. TGU is a mature Clear Fork waterflood about 20 miles east of Big Spring, Tex. The Clear Fork consists of three producing intervals: Upper, Middle, and Lower with 2,200-3,300 ft total depth. Estimating the contribution of each interval is difficult since it is likely that the lower two zones may be covered with fill, as observed in the lower two zones in the TGU 912W injection well when the ORT was run into it. Due to the fill issue, the ORT was set across the Upper Clear Fork perforations.

Estimated AOI for the device was defined as a 1-mile radius surrounding TGU 912W encompassing a total of 32 active producing wells and 6 active injection wells. Not all injection wells were active on a continuous basis.

Before ORT installation, the operator supplied individual well production and injection histories from January 2015 through end-2020. Analysis of historical data showed that:

- The average decline rate in the AOI was 14.5% through July 2020, when several wells were shut in.

- Overinjection into the asset’s AOI occurred during that time frame, with cumulative overinjection of almost 310,000 bbl by July 2020. Overinjection is supported by the fact that injection well shut in pressures were 800 psi or more.

- Despite overinjection, average oil production in the AOI continued to decline to 150 bo/d by July 2020 from 320 bo/d. Per well production declined to 4.6 bo/d by July 2020 from 7.4 bo/d when several wells were shut in due to low oil prices and the pandemic.

- Only about 21 wells were producing on average from August 2020 through June 2021. Average production per well during that time was 4.2 bo/d.

- Decline rate for the AOI increased to 38% from August 2020 through May 2021.

- Average injectivities into the six injection wells within the AOI ranged from 0.1-0.3 b/d-psi.

ORT operation

The ORT began full 24-hour operations in May 2021, and a quantifiable response was identified beginning in June 2021. The operator returned shut-in wells to production by August 2021. In late October 2022, a weather-related event knocked out power to the injection well and the device. To further evaluate the device’s production improvement potential, it was left downhole but shut off, and injection into the TGU 912W was re-routed to other injection wells where the ORT’s operation had improved injectivity.

Fig. 5 shows the AOI daily oil production with respect to cumulative overinjection. The purple line plots the cumulative difference between water injected and oil and water produced. The operator reduced injection from October 2020 through August 2021, then returned to overinjection with increased injectivity resulting from the ORT’s operation. In March 2022 HAI recommended that the operator balance injection and withdrawal from the AOI because overinjection was potentially reducing production.

In addition to the production increase and reduction in decline rate, the ORT materially increased injectivity of the well in which it was installed as well as the other active injection wells within the 1-mile radius area. Reservoir heterogeneities associated with carbonate reservoirs resulted in varied improvements. The smallest improvement occurred in an injection well about 1,300 ft from the TGU 912W while the largest improvement occurred in a well about 5,100 ft from TGU 912W.

ORT economics

The author

John H. Benton ([email protected]) is chief development officer for Hydroacoustics Inc. in Rochester, New York. John holds a BS (1978) and MS (1984) in petroleum engineering from the Colorado School of Mines. He is a member of the Society of Petroleum Engineers, the Society of Petroleum Evaluation Engineers, and the Rocky Mountain Association of Geologists and is a Colorado registered professional engineer.

Bibliography

Beresnev, I.A. and Johnson, P.A., “Elastic-wave stimulation of oil production: A review of methods and results,” Geophysics, Vol. 59, No. 6, June 1994, pp. 1000-1017.

Cidoncha, J.G., “Application of Acoustic Waves for Reservoir Stimulation,” SPE 108643, International Oil Conference and Exhibition, Veracruz, June 27-30, 2007.

Daley, T. and Majer, E., “Borehole Seismic Monitoring of Seismic Stimulation at Occidental Permian Ltd’s – South Wasson Clear Fork Unit,” Lawrence Berkeley National Laboratory, LBL Publications, Apr. 30, 2007.

Irfan, M., Lenn, C.P., and Ghosh, D., “Seismic Stimulation and Induced Seismicity in Oil Reservoirs: A Review of Applications to Enhanced Oil Recovery (EOR),” Proceedings of the International Conference on Integrated Petroleum Engineering and Geosciences, Springer Nature Singapore Pte Ltd., 2016.

Jeong, C., Kallivokas, L.F., Kucukcoban, S., Deng, W., and Fathi, A., “Maximization of wave motion within a hydrocarbon reservoir for wave-based enhanced oil recovery,” Journal of Petroleum Science and Engineering, Vol. 129, May 2015, pp. 205-220.

Pride, S.R., Flekkøy, E.G., and Aursjø, O., “Seismic stimulation for enhanced oil recovery,” Geophysics, Vol. 73, No. 5, Sept.-Oct. 2008, pp. 23-35.

Reichmann, S., Giese, R., and Amro, M., “Acoustic wave stimulated enhanced oil recovery,” Geophysical Research Abstracts, Vol. 15, Apr. 1, 2013.

Sitompul, V., Alfian, M., Sitompul, F.O., Winata, D., Diharja, T., Sutadiwiria, G., Paryoto, S., Dusyanto, E.D., Rahadian, R., Erwanto, P.E., Triwanto, A., Sumirat, I., Alfajri, R., Persero, P., Ekalaya, M.A., Nurrakhman, A.A., Asy’ari, H., and Tbk, PT.E., “Breakthrough Enhanced Oil Recovery Technology with Low Cost & Fast Yield on Pilot Test of Vibroseismic EOR Technology in Tempino Field,” SPE-205746-MS, SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, virtual, Oct. 12-14, 2022.

Wooden, B., “Seismic Stimulation: An Eco-Friendly, Effective EOR Alternative,” Journal of Petroleum Technology, Vol. 70, No. 8, Aug. 2018, pp. 21-23.