Polyacrylamides replace Guar for offshore completions

Deep offshore fractured wells require high surface-treating pressure to achieve required bottomhole pressures for treatment. These pressures can reach frac-boat limits and need to be accurately predicted to design and optimize the fracture design. Weighted Guar-based gels hydrostatically increase bottom-hole pressure to lower surface treating pressures (STP), but wellhead pressure data from Shell PLC’s offshore Gulf of Mexico completions show that higher-weight brines increase friction and STP beyond expectations.

Polyacrylamide polymers have long been used as high viscosity friction reducers (HVFR) in land-based multifracture wells. They have also demonstrated good solids-transport capacity in clean-out operations. These fluids, therefore, should be applicable to offshore operations for Guar replacement with suitable adjustment to rheology properties for effective proppant transport through typical temperature variations and restrictions in offshore and deepwater wells.

Polyacrylamide is compatible with seawater or NaCl brine and offers advantages in cost and controllable viscosity compared with crosslinked Guar gels. Polyacrylamide solutions are at neutral pH and therefore have fewer scaling tendencies with seawater or formation brines than high pH borate gels.

To replace crosslinked Guar in offshore deep multifrac and frac-pack service, researchers have investigated polyacrylamide properties with high-concentration polymer in solution to increase proppant transport capacity. The results show that the polymer is capable of transporting proppant to the formation with less formation damage and better proppant conductivity than comparable standard Guar-based fluids.

Deep offshore well fracturing

Friction pressure for deep offshore well completions (> 20,000-ft MD) are difficult to predict because of high reservoir pressures, internal upset restrictions, cold seafloor temperatures, crosslink delay, and multiple casing strings. Ultradeep wells, up to 30,000-ft TVD, add friction due to their length. If these wells are to be drilled using managed pressure drilling (MPD), the pressure control equipment also adds friction by restricting casing string sizes.

Friction losses can be offset by weighting the fluid to increase hydrostatic pressure. Heavy-weight Guar-based fracturing fluids have been developed up to 13.5 lb/gal (ppg) using monovalent bromide brines. Results from these fluids are mixed, and new fluids based on existing polyacrylamide high-viscosity friction reducers are being investigated for proppant transport to overcome crosslinked Guar-gel limitations.

Deepwater friction prediction

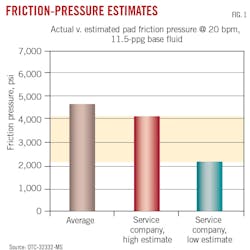

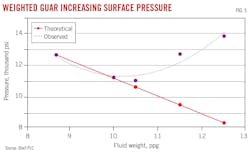

Accurate friction-pressure calculations require onsite model calibration using pressure data while pumping fluid. A study of service company friction pressure estimates for an 11.5-ppg frac fluid showed that the estimates were inaccurate and below average measured pressures (Fig. 1). In the worst case, the lowest estimated friction pressure was about half the highest measured friction pressure.

Downhole gauges provide the most accurate data for friction pressure calibration. Without gauges, calibration can still be made using a live annulus and an accurate brine weight estimate. Fluid compressibility and density variations with temperature, however, result in brine weight and resultant hydrostatic pressure uncertainty. Shell’s analysis of measured brine weights using bottom-hole gauge data in 30 wells showed an average of 1.5% deviation from planned brine weights.

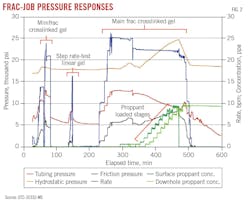

Even with gauges, friction measurements are complicated by fluid variations as the job progresses from linear gel in the step-rate test to crosslinked gel in the main frac treatment. Additional uncertainty in crosslinked gel properties occurs during shearing through tools and perforations (Fig. 2). Calibration of friction pressure during the pad stage in the main frac may not accurately capture friction of the proppant-laden gel in the job.

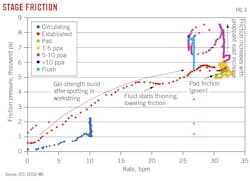

A detailed analysis of the friction pressure during a typical frac job is shown in Fig. 3. The data demonstrate non-linear friction pressure changes with rate throughout the job. At the start of the job, gel strength builds when it is spotted (dark blue data). During the injection-rate test, the gel shears-thins as it is pumped down the workstring at high rates and through the tool crossover (red data). During the frac-job pad stage (green data) the gel starts with similar friction pressure to the injection-rate test and then dramatically increases during proppant stages (magenta data). For this treatment, the highest friction pressure was observed in the 10 lb/gal added (ppga) proppant stage. Friction pressure decreased during the flush stage when the pumped-in gel no longer contained proppant.

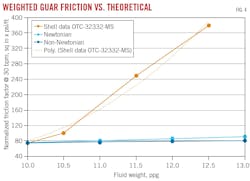

Fig. 4 shows effects of Guar fluid density on friction pressure based on treatment analysis from wells with similar work-string configurations. For direct comparison, the data were normalized to well length and total workstring pipe area. The data do not match expected friction pressure trends based on fluid density for either Newtonian or non-Newtonian fluids. Friction pressure should increase linearly with weight based on Reynolds number (Equations 1-5), but the weighted Shell Guar fluids follow a quadratic trend.

Increasing frac-fluid weight will reduce surface treating pressure by increasing hydrostatic from 8.7 ppg to 10 ppg, but beyond this weight Shell’s surface treating-pressure data show increasing pressure that negates the advantage of weighted brines (Fig. 5). Shell has attempted to address this discrepancy with mathematical models but has not yet yielded a solution, probably due to the number of real-world well and fluid variables (including fluid-weight uncertainty) affecting measured friction properties.

Polyacrylamide Guar alternative

To address crosslinked Guar-based fluid limitations, researchers have turned towards linear polyacrylamide-based polymers. They promote laminar flow for friction reduction to reduce pumping pressure, and derivatives of this polymer show good proppant transport ability.

NexTier Oilfield Solutions conducted friction studies of polyacrylamide to reduce frac-spread fuel consumption and emissions. Friction tests with HVFR formulated with synthetic Permian basin produced water containing 115,471 ppm total dissolved solids (TDS) showed that too much friction reducer is as detrimental to friction as too little, with a minimum in friction between 0.8-1.2 gal polymer/1,000 gal brine (gpt). The effect is like the weighted Guar results in Fig. 5, but in this case the increase in friction is due to excessive polymer rather than excessive brine weight.

A frac efficiency model estimated fuel consumption, greenhouse gas emissions, and total cost for each pump based on surface treating pressures due to a combination of hydrostatic head, pipe friction, and perforation friction pressures. Pipe friction accounts for 40% or more of the overall surface treating pressure, and for typical 70-120 bbl/min land multi-fracture jobs pumped down 15,000 ft of pipe, 22.5% fuel savings were calculated using 1 gpt HVFR.

Proppant transport

Polyacrylamide fluids were originally developed for friction reduction, but their solid-carrying capacities have been exploited for wellbore cleaning in land-based hydraulic fracturing service. Weatherford International PLC expanded this application to proppant transport by performing rheology and solids suspension tests over a range of polymer loadings and proppants.

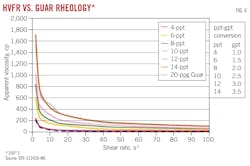

Rheology tests included HVFR solutions loaded with 4-, 6-, 8-, 10-, and 14-lb polymer/1,000 gal water (ppt) solutions, equivalent to 1.0, 1.5, 2.0, 2.5, and 3.5 gpt, respectively. These solutions were compared with a 20 ppt Guar solution. The tests included a range of shear rates and temperatures.

Fig. 6 shows apparent viscosity of the fluids. The 4-ppt polyacrylamide solution yielded a rheological profile similar to 20-ppt Guar and had better thermal stability, showing less temperature thinning than observed in the Guar fluid.

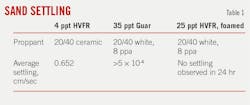

Proppant settling tests included ceramic 16/20, 20/40, 30/50, 16/20 resin-coated, and 20/40 resin-coated proppants in a fast-hydrating polymer which can be mixed on the fly or hydrated in batch mode. Single proppant grains were dropped in the polymers, and proppant settling was defined as the time for the proppant to pass between two points 38.3 cm apart in a glass tube. Proppant suspension tests were conducted with a foamed 25-ppt polyacrylamide fluid and compared with a 35-ppt Guar fluid. Both fluids contained 8-ppa 20/40 white sand with a small amount of 16/30 black bauxite for markers, and settling was observed in a glass cylinder.

Table 1 lists 20/40 proppant settling rates at room temperature for 4-ppt polyacrylamide, 25-ppt foamed polyacrylamide, and a 35-ppt Guar (without crosslinker). The low-loading HVFR fluid yielded higher sand settling than the Guar system, but the foamed system with higher polymer loading exceeded the proppant suspension of the Guar.

Polyacrylamide breakers

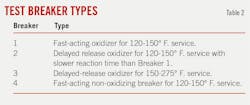

To investigate the interactions of breakers on polyacrylamide polymers, Finoric LLC performed breaker tests on five commercial anionic polyacrylamide polymers using four commercially available breakers. Three breakers were oxidizers based on thermal decomposition of a peroxide precursor such as persulfate, but one did not operate via a thermally-activated radical degradation mechanism and was more suitable for low temperature applications. Table 2 lists breakers details.

The tests evaluated variations in both breaker and polyacrylamide chemistries to determine optimal combinations of breaker with polymer. The results at 130° F. show degradation in viscosity at 85 s-1 shear rate over time as the breaker cuts polymer chains into lower molecular weight species. Polyacrylamide initial dynamic viscosity is between 45-65 cp, depending on the polymer, and decreases within 1.45 hr to generally the lowest level attained during the tests. Three of the polymers declined to about 10 cp, but two were still above 20 cp. At 200° F., all polymers reacted generally the same, with rapid degradation in viscosity to below 5 cp within 15 min. At 200° F., proppant carrying capacity could be severely compromised early in treatments with this breaker.

HFVR 1 and HFVR 5 were at the top of the viscosity curves at both temperatures. This indicates that these polymers had a significantly different derivation than the other polymers, but this could not be verified since the actual polymer structures were proprietary.

The results show that backbone structure makes a difference in degradation times and effectiveness, and these issues should be studied in detail before deciding upon a polymer-breaker package. Some service conditions, ultra-deepwater vs. shallow land wells for example, could require a robust polymer capable of handling large temperature fluctuations in the riser and needing long break times to effectively transport proppant into the reservoir. The shallower wells can take advantage of more fragile polymer versions or aggressive breakers to affect more efficient break for better flowback and lower formation damage.

Breaker 3 did little to reduce viscosity at 130° F. due to the encapsulation of the breaker to delay its dissolution at high temperatures. It degraded the polymers effectively at 200° F., however, to achieve 10 cp viscosity in 1.45 hr. This breaker, therefore, would not be recommended for sub-150° F. service based on the extended breaker times.

Breaker tests over a range of temperatures yielded a family of curves for each polyacrylamide solution that outline optimal operating conditions to provide break times long enough to maintain proppant transport but not so long as to incompletely break the polymer or require excessive stand-by time waiting for polymer to degrade. Operators should be wary if polyacrylamide polymers are altered by the service company due to cost, availability, or other reasons without subsequent testing to ensure the breaker packages perform as expected.

Highly loaded polyacrylamides

The polyacrylamide breaking results above contain polymers in the 4-10 gpt range which are typical for onshore multi-frac cleanout service. To replace crosslinked Guar in offshore deep multifrac and frac-pack service, however, Shell investigated polyacrylamide with 40 gpt polymer in solution to increase proppant transport capacity. This polymer loading yields fluids with 400-800 cp viscosity compared with 45-55 cp for the polymer solutions in the Finoric tests. The 25 ppt HFVR foamed system in Table 1 showed high proppant suspension, but foamed systems are incompatible with deep, high-pressure offshore downhole conditions.

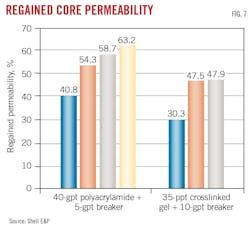

Fluid loss and regained permeability tests on a 640 md Berea core at 150° F. with a high-concentration polyacrylamide containing a breaker showed 63% regained core permeability with continuing improvement throughout the test (Fig. 7). By comparison, 35 ppt borate crosslinked Guar gel yielded only about 50% static regained permeability. The polyacrylamide required half the amount of breaker than the crosslinked Guar to achieve these results, indicating that both cost and offshore environmental and fluid disposal compliance can be improved with this fluid system.

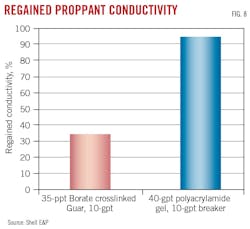

Proppant conductivity tests showed similar results. Tests were performed with 2 lb/cu ft high density proppant at a commercial lab following API standard procedures. A 35-ppt borate crosslinked Guar fluid was compared with a 40-gpt polyacrylamide fluid. Both fluids were made in 5% NaCl and used 10 gpt of breaker. The polyacrylamide yielded an average of 94% regained conductivity compared with Guar which had an average of 35% regained conductivity (Fig. 8).

HVFR degradation

Formation damage is an additional concern regarding proper breaker selection for polyacrylamides. These polymers led to formation damage due to semi-solid particle formation from interaction of the acrylate or acrylic acid in the polymer with cationic metals, specifically in formations with high iron content. For example, degradation species have been especially prominent in the iron-heavy Woodford shale. Once formed, these particles are difficult if not impossible to remediate.

Overtreatment of the polymers with oxidative breakers to reduce their viscosity for flowback results in oxidation of Fe+2 species to Fe+3, which negatively affects polyacrylamides in both viscosity and formation damage. Prior sequestration of ferric irons with chelating agents has not been a practical solution.

Tests conducted on cationic and anionic polyacrylamides by Solvay Flourides LLC showed that both types of polymers were affected by iron, though through different mechanisms. For anionic polymers, a coagulant formed in the presence of Fe+3 neutralizes polymer-strand surface charges and produces large aggregates and flocculants.

For cationic HVFRs, no coagulation was observed at room temperature under low pH due to electrostatic repulsion, but a crosslinked gel formed after raising pH under typical reservoir temperatures (> 100° F.). The polymer underwent a facile hydrolysis reaction, turning the cationic polymer to anionic and proceeding according to anionic polymer degradation pathways. Based on zeta potential measurements of the polymer solution, hydrolysis occurred under neutral pH at temperatures as low as 120° F.

Amphoteric polymers behaved similarly to cationic FRs, with slight crosslinking at 5-7 pH under room temperature. Gummy precipitates formed after heat treatment.

These learnings allowed development of a novel HVFR fluid which showed fast hydration and high friction reduction in both fresh water and synthetic brines. No rubbery precipitates formed even in the presence of 500 ppm ferric iron over a wide range of pH and salinity.

Bibliography

Beveridge, Z., McLaughlin, N., and Kakadjian, S., “Managing Friction Pressure to Reduce Fuel Consumption and Emissions for a Fracturing Fleet,” SPE-217783-MS, SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, Tex., Feb. 6-8, 2024.

Busteed, J.E. and Fragachan, F.E., “Development of Unique, Non-Damaging, Non-Crosslinked Solids Cleanout Fluid System with Enhanced Solids Suspension Capacity,” SPE-212426-MS, SPE Argentina Exploration and Production of Unconventional Resources Symposium, Buenos Aires, Argentina, Mar. 20-22, 2023.

Dreyer, D., Garza, D., and Kurian, P., “Evaluation of the Performance of Chemical Breakers on Various Types of High Viscosity Friction Reducers,” SPE-21778-MS, SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, Tex., Feb. 6-8, 2024.

Lizak, K.F. and Zhang, Y., “Fracturing 30,000 ft Wells in Deepwater, Planning and Execution Learnings from the Gulf of Mexico,” SPE-217802-MS, SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, Tex., Feb. 6-8, 2024.

Lizak, K.F., Summach, C.J., and Zhang, Y., “Heavy-Weight Crosslinked Gel Frac Fluids – How Much Bang for the Buck Do We Really Get?,” OTC-32332-MS, Offshore Technology Conference, Houston, Tex. May 1-4, 2023.

Sun. H., Lin., Y., Geng, X., Wickramasinghe, L., Zalluhoglu, F., and Wang, Q., “Engineering a Synthetic Friction Reducer to Combat Undesirable Formation of FR-Metal Complex/Precipitation in Slickwater Fracturing,” SPE-217763-MS, SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, Tex., Feb. 6-8, 2024.

Vitthal, S., Zanten, R.V., Reynolds, M., Lizak, K., Malbrough, J., and Xueyong, G., “Unconventional Technology Moves To Conventional Reservoir,” IP.com Journal, Sept. 20. 2023.

About the Author

Alex Procyk

Upstream Editor

Alex Procyk is Upstream Editor at Oil & Gas Journal. He has also served as a principal technical professional at Halliburton and as a completion engineer at ConocoPhillips. He holds a BS in chemistry (1987) from Kent State University and a PhD in chemistry (1992) from Carnegie Mellon University. He is a member of the Society of Petroleum Engineers (SPE).