Efficiency Gains Improve Bakken Production

Although the number of rigs at work in the Williston basin peaked more than a year ago, production in the Bakken-Three Forks tight oil play continues to grow as operators like Continental Resources find new ways of reducing the amount of time it takes to drill a well and improve completion techniques to enhance recovery.

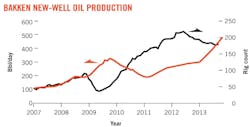

Production remains on a steady upward growth trajectory even though the number of rigs working in the Williston basin is well below its peak monthly average of 220 rigs recorded in June 2012. Baker Hughes reported an average 182 rigs at work in the basin as of October 2013.

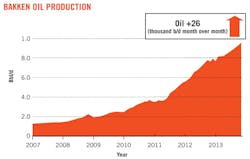

Williston basin production totaled 899,266 b/d in June 2013, up 23% from the same month in the prior-year period and more than four times the 214,344 b/d reported in June 2007. Figures from the North Dakota Pipeline Authority show that Williston output has quadrupled in the past 6 years and is well on its way to reaching 1 million b/d.

The bulk of June production came from North Dakota (821,598 b/d), with smal contributions coming from eastern Montana (72,887 b/d) and South Dakota (4,781 b/d).

Output from the Peace Garden State reached an all-time high of 911,242 b/d in August 2013, up 89,644 b/d from June and 209,833 b/d higher than during the same period in 2012. More than 95% of North Dakota drilling targets the Bakken-Three Forks.

Underpinning production growth are efficiency gains that are apparent in the Energy Information Administration's inaugural Drilling Productivity Report.

The agency's October report figures the average rig working in the Bakken will add 482 b/d of oil and 463 Mcfd of new gas production in November, marking an improvement of 23 b/d of oil and 18 Mcfd of gas over the prior month period.

Manufacturing mode

The drive to optimize development activity in the Bakken-Three Forks is apparent in efforts under way at Continental Resources. The company is drilling more wells from a single pad and proving up the productivity of the previously untapped second and third benches in the Three Forks.

Continental's Hawkinson unit density drilling pilot program is one example of these efforts.

The Hawkinson project demonstrates the productive potential of drilling wells into multiple, stacked pay zones. The unit, which spans 1,280 acres in Dunn County, N.D., was initially tested at a combined monthly rate of 14,850 boe/d from 14 wells—including 11 new wells and three existing wells.

The Hawkinson unit is unique in that it contains several sets of wells targeting different zones from the same drilling pad. Hawkinson includes four wells targeting the Middle Bakken, three targeting the Three Forks 1, four targeting the Three Forks 2, and three targeting the Three Forks 3. The wells were spaced 1,320 ft apart in the same zone and offset 660 ft in adjacent zones.

Warren Henry, vice president of investor relations for Continental, told UOGR that the Hawkinson unit is an example of a larger transition under way in the Bakken.

"Eighteen months ago we and the other operators were busy exploring the play and drilling single wells primarily to hold acreage," Henry said. Now that much of the early work is done, he said the focus is shifting toward becoming more efficient with pad operations.

"It's just a matter of moving into full manufacturing mode," Henry said.

Drilling more wells from a single pad enables wells to be drilled more quickly, reduces mechanical problems by allowing companies to become familiar with the rock in a given area, and allows midstream vendors to run all of the oil, natural gas, and water pipeline to a single place with significant volumes.

Other advantages include the use of a single road, one electrical system, and one large tank battery complex to hold oil and flowback water.

"It's very efficient and it's concentrated, so it greatly reduces the surface impact," Henry said. Continental also is testing mega-well pads that can hold from 14 to 30 wells each on just 20 acres—a space that would ordinarily hold just four single wells, which have an individual surface impact of about five acres each.

All of this translates into savings and rising production for Continental. The company operated 20 rigs in the play during the third quarter and its production rose to an average of 94,500 b/d, up 51% from the same period a year earlier. Henry added that Continental's cost of drilling and completing a Bakken-Three Forks well has fallen to $8 million from $9.2 million in the past year and a half.

The company drilled its first commercial Bakken well in 2004 and remains the Bakken-Three Forks' biggest producer, most active driller, and largest leaseholder at around 1.2 million net acres.

In a call to discuss third-quarter results, Continental Chief Operating Officer Rick Bott said there is clearly more oil to be recovered in the play than was previously perceived and projects like Hawkinson are leading the way to defining the optimum drilling density and pattern to maximize oil recovery.

"The Bakken just keeps getting better," Bott said.