Production history provides CBM insights

A review of previous coalbed methane (CBM) case studies explains why some seams produce at ever increasing rates while others undergo production declines.

Over the past 2 decades, coalbed methane (CBM) has already produced more than 28 billion cu m (1 tcf) of annual production from 300 billion cu m of proved reserves."1 CBM exploration continues in countries such as Australia, China, and India, all of which have large deposits of coal.

In this work, technology continues to play a leading role because the reservoir properties require special analysis and techniques for the economical production of CBM.

Whereas Darcy's linear flow equation describes conventional oil and gas production, for example, a combination of gas desorption and diffusion through the micropores into coal cleats, followed by linear Darcy flow along these fractures into the wellbore, best represents CBM production.

CBM properties

Gas content, "completable" thickness, gas saturation, and coal permeability comprise the four key properties that govern CBM production. Completion and stimulation technologies are also important for commercial rates of production from wells.

It is well known that the higher the coal's absolute permeability, the higher the production rates, with all other conditions remaining the same. But it is not yet clearly established as to why certain wells produce CBM at inclined rates while others follow standard production declines after overcoming an initial "negative" decline.

An analysis of the diagnostic differences in CBM reservoir properties can help engineers and geologists simulate reservoir characterization and optimize field development. In this way, the operator should realize no surprises in production.

For this purpose, certain theoretical, experimental, and field results can be pooled. As Gray states, "As fluid pressure decreases without desorption, all permeabilities reduce. Then, depending on shrinkage associated with desorption, the permeability may increase or continue to decrease as fluid pressures continue to drop."2

Harpalani's experiments also showed that permeability increases upon the commencement of desorption.3 Before desorption, however, permeability decreases.

Levine performed a more precise experiment that led him to conclude that desorption causes changes in volumetric strain, which in turn results in matrix shrinkage and a consequent increase in coal permeability.4

Furthermore, Palmer and Mansoori proposed a theory that relates the changes in porosity of the natural fracture system, which is a function of pore volume, with the compressibility and desorption of gas pressure.5 This theory assumes values for linear elastic rock mechanics, small fracture porosity, and the presence of gas in the fractures and goes on to relate absolute permeability to porosity by a cubic law equation.

As a result, a high expansion of permeability for a given porosity expansion can be implied.

These experimental and theoretical results show that when a CBM reservoir is fully saturated (including fractures with some gas), permeability will increase from the very beginning and continue to rise for some time.

Ever-increasing gas rates

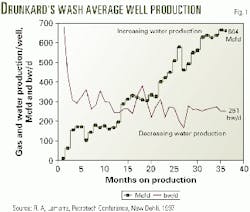

In theory, the gas production rate will increase throughout the life of the well. The Drunkard's Wash Project in Utah, with production from the Ferron coals, provides an excellent example of this phenomenon.

According to Robert Lamarre, senior geologist of Texaco for this field, "CBM production continues to increase due to drilling additional wells and the increase in gas rates from older wells since 1992."6

Currently, 380 wells produce 210 MMcfd and only 5 wells have undergone declining gas rates after 9 years of production.

The remaining wells have either continued to increase in production or have stabilized rates (Fig. 1).

Drunkard's Wash field fits with Palmer-Mansoori's theory as well as the experiments of Levine and Harpalani. Overpressured formations and probable updip gas migration along the coals from deeper sections also represent the reservoir characteristic of this field.

Field evidence also comes from other sources such as the Valencia Canyon wells in San Juan basin reported by Mavor and Vaughn (OGJ, Apr. 26, 1999, p. 35).7

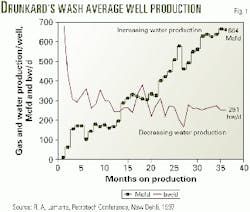

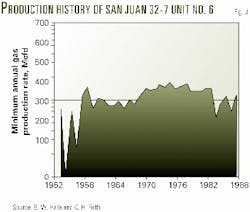

Brandenberg cited production rate rises in the San Juan "fairway" for a large number of wells.

These wells have high permeabilities, high pressure, and appear to be saturated; although some dewatering was needed in the beginning (Fig. 2).

Dynamic openhole stimulation (cavitation) appears to be the driving mechanism for the rise in production. The rise in rates from year to year, however, is believed to be a result of the coal reservoir properties much as it is with the Ferron coals.

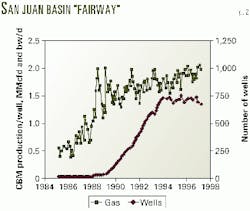

Hale & Firth presented a detailed case of San Juan 32-7 Unit No. 6 well in the northern San Juan basin.8 This well, originally designated the 6-7 San Juan 32-7 Unit, was completed by Phillips Petroleum Co. in August 1953. Over a 34-year period, this Upper Cretaceous Fruitland CBM well produced more than 1.364 MMcf of gas with no decline in production or reservoir pressure. The producing reservoir is moderately overpressured (0.47 psi/ft).

Fig. 3 shows that the production rate remained remarkably constant except for a few anomalous months. Pressure build-up tests conducted in 1978 showed an extrapolated reservoir pressure of 1,502 psig, which was extremely close to the pressure measured 25 years earlier at 1,504 psig.

This shows that there was no measurable pressure depletion. This well is one of the oldest continuously producing CBM wells in the US and perhaps the world.

But it was completed long before the CBM industry took shape. The well was never simulated and no significant water production was reported.

This case history is presented here in brief because it gives some additional support to the possibility of long-term production capabilities of CBM without any decline, especially when well-developed cleats are present. A quick study of the reported fully saturated CBM fields in the US indicates that good cleats are present in these reservoirs.

Undersaturated coal seams

Some workers have tried to determine why only undersaturated coals show lower gas rates after the initial "negative" decline.

"In studying the invasion of a wetting phase fluid into a simulated fracture completely saturated by a non-wetting phase fluid, the effects of trapping for multiphase flow through a fracture are brought out by a dramatic reduction of relative permeability (6% of absolute permeability) and a high residual nonwetting phase saturation (60%) in the model."9

Pryak-Nolte reached this conclusion from a simulation study of multiphase flow in a fracture.

Depending on the coal characteristics, desorbed gas can initially give rise to production increases by displacing the water through the cleat and fracture system.

But once the limit of irreducible water saturation is attained, the gas rates are arrested, followed by falling production throughout the life of the well.

This phenomenon occurs under ordinary percolation with inlet accessibility and trapping that may characterize unsaturated coals. But in saturated and super-saturated coals, trapping is believed to be absent or negligible.

In this case, ordinary percolation with global accessibility and inlet accessibility become the defining factors as both the wetting phase and nonwetting phases occupy the fractures and fissures.

But why should there be a decline shortly after desorption? What is the inhibition against the matrix shrinkage and porosity increase that brings about greater permeability-as is the case with saturated reservoirs?

No experimental study conducted to date on undersaturated reservoirs has answered this question. But a view can be taken that two factors create a condition of declining rates.

First, permeability decreases due to increases in horizontal stress during the dewatering process absent desorption. Another factor is the reduction in the rate of desorption when the desorption starts at a pressure lower than initial reservoir pressure.

In this case, the adsorption isotherm shifts by moving the reservoir pressure point towards the desorption pressure point. Thus, this produces an environment in which there is more gas content to desorb, yet a slower desorption rate remains in place relative to the desorption pressure point.

This raises the following issue. Do recoverable reserves decrease as the adsorption isotherm shifts horizontally? A good starting point for investigating these questions can be conducted by evaluating gas trapping mechanism of water.

Because cleats are water-filled, gas diffuses to the cleat system when desorption pressure is reached. Additionally, water is a non-wetting phase while gas is a wetting phase. Thus, the wetting phase fluid traps the nonwetting phase fluid (water) at local maxima in the fracture aperture distribution.

The effect of trapping in the analysis of multiphase flow through fractures is said to result in a high residual non-wetting phase (water) saturation and a very low relative wetting phase permeability (gas).

Thus, the trapping of brine or water by methane reduces the percent saturation possible for methane and reduces the flow of methane through the fracture.

The foregoing arguments can help us to identify CBM reservoirs that will produce "every-increasing" gas rates with high reserves during the exploration phase through the evaluation of certain reservoir properties and characteristics. Simulation of these reservoirs will require the use of rising permeability values over the years considered.

The observed increases in permeability mentioned in the published articles can serve as a guide to fix these values for simulation purposes or in material-balance calculations.

History matching can later be attempted by suitable changes to these assumed values.

This diagnostic technique will be helpful not only in US but for new CBM frontiers like India, China, and Russia where some saturated and supersaturated CBM reservoirs are believed to be present at depth.

Countries like India need to accurately calculate long-term production potential in order to evaluate gas supply contracts with independent power producers on take-or-pay basis.

Unlike the US, though, these CBM projects will have to stand on their own for marketing purposes as there are no gas pipelines going near the likely CBM producing blocks.

References

- Brandenberg, C.F., McBane, R.A., Schraufnagel, R.A., and Kuuskraa, V.A., "Coalbed Methane and Technology, Relating the U.S. experience into international opportunities," World Energy Conference, October 1998, Houston.

- Gray, I., "Reservoir Engineering in coal seams: The physical process of gas storage and movement in coal seams," SPE Reservoir Engineering, February 1987, pp. 28-34.

- Harpalani, S., "Permeability changes resulting from gas desorption," Methane from Coal Seams Technology, June 1989, pp. 58-61.

- Gayer, R., and Harris, I. (editors), Levine, J., "Influence of Matrix Shrinkage on permeability," Coalbed Methane and Coal Geology, Geological Society of London, 1996, pp. 197-212.

- Palmer and Mansoori, "How permeability depends on stress and pore pressure in coalbeds," SPE paper 36737, presented at the Annual Technical Conference and Exhibition, Denver, Oct. 6-9, 1996.

- Lamarre, R.A., and Burns, T.D., "Drunkard's Wash Project: Coalbed Methane Production from Ferron Coals in East Central Utah," Petrotech Conference, New Delhi, Jan. 12, 1997.

- Mavor, M., and Vanghn, J.E., "Increasing absolute permeability in San Juan Basin Fruitland formation," International CBM Symposium, Tuscaloosa, Ala., May 12-16, 1997.

- Hale, B.W., and Firth, C.H., 1988 Production history of the San Juan 32-7, Unit No. 6 well, Northern San Juan Basin, New Mexico, in Fassett J.E. (ed) Geology and Coalbed Methane Resources of the Northern San Juan Basin, Colorado and New Mexico, Rocky Mountain Association of Geologists, Denver, 1988, pp. 199-204.

- Pyrak-Notle, L.J., "Multiphase Flow in a fracture," Proceedings of the CBM Symposium, Tuscaloosa, Ala., 1991, pp. 433-42

The author

Gopal Ramaswamy is managing director for Reliance Gas (P) Ltd. and advisor for Reliance Industries Ltd. He holds a PhD in physics. From 1952 to 1962, Ramaswamy worked as a geophysicist for an ExxonMobil Corp. subsidiary, Stan-Vac, in India, then later as consultant for Petrobras form 1963 to 1964. He also served as an exploration advisor for the Indian Ministry of Petroleum & Chemicals (1970-80) and was in charge of exploration and development of the Bombay High oil and gas fields. In the early 1990s, Ramaswamy served as the senior author of the first CBM studies in India that led to the drilling of three promising CBM wells in the Cambay basin and other wells in the eastern coal fields.