Canadian heavy crude production seen rebounding early next decade

Steven J. Kelly

Purvin & Gertz Inc.

Calgary

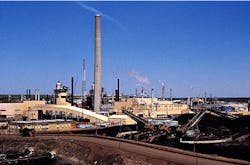

Syncrude Canada Ltd.'s oilsands plant in the Athabasca oilsands area of Alberta has been a major contributor to a recent rise in heavy oil production in Western Canada. This aerial view shows the plant facing northeast, with the feed dump pocket on the right and the extraction plant on the left. Photo courtesy of Syncrude Canada.The Canadian heavy crude oil sector has taken some tough knocks in the past year. The blows came mainly as a result of fallout from the Asian financial crisis and a resulting decrease in petroleum demand and oil prices.

Prices for Canada's heavy crudes fell to all-time lows during the first quarter of 1998. And production growth that was healthy during the first part of this decade has slowed considerably. The rate of growth in Canada's heavy oil output is now expected to fall further until 2002. Market fundamentals have certainly shifted, and Canada's heavy crude industry is expected to remain in a slump in the near term. But a rebound in global petroleum demand should return Canada's heavy oil market to its former healthy state early in the next decade.

A detailed look at the factors that affect the heavy oil market in Canada will explain what led to its current hibernation period and how it will recover.

Recent history

Canadian production of medium and heavy crude oil has increased by 35% since 1995, to reach a record level of more than 825,000 b/d in 1998. Production increases have been recorded for all grades of heavy crude, including Alberta and Saskatchewan conventional grades and Alberta bitumen.The strong gains in heavy crude supply can be attributed to a combination of favorable developments. Technological advances have reduced the cost of producing these reserves and have opened new areas for development. Market growth has occurred in the key U.S. Midwest and Rocky Mountain export markets, as refiners expanded their capacity to process heavy crude. These U.S. heavy crude refineries process mainly Canadian heavy oil because of its greater availability and its good performance in coking units and asphalt production. And equally important was a period of robust commodity pricing, which brought a strong influx of equity capital to the Western Canadian industry.

The rapid growth in Canadian heavy crude production over the past several years has not occurred without problems, however. Pipeline systems had difficulty keeping pace with the rapid increase in heavy crude and synthetic crude production, leading to continuous capacity apportionment. Inland markets were oversupplied with heavy crude. As a result, alternative markets on the U.S. West Coast were found for some Canadian heavy crude supplies, which lowered the netback prices on all grades.

In addition, the supply of light hydrocarbons for use as heavy crude diluent became particularly tight due to high demand from new bitumen production. A sharp price response to this imbalance contributed to even lower netback prices for a time.

From an analysis of the crude oil markets in the U.S. Midwest, Purvin & Gertz estimates that the netback price for bitumen dipped to an average of just above $5/bbl in 1998, down from more than $14/bbl only 2 years earlier. [Note: All price figures presented in this article are in U.S. dollars.]

The constraints to growth of heavy crude markets may be related to the framework shown in Fig. 1 [40,321 bytes]. In recent years, rapid growth has resulted in a dominant focus on producers' issues-namely, market expansion and diluent availability. The downturn in global markets has dramatically shifted the emphasis to refiners' issues, such as security of supply. Producers and refiners have also contended with infrastructure issues that have limited market growth in the past.

Global heavy oil outlook

The developments in Canada are not unique, and must be considered in a global context. World heavy crude production will be limited by low crude prices in the short term.The large producers of heavy crude in the Western Hemisphere include Venezuela, Mexico, the U.S., and Canada. Other Latin American countries, such as Ecuador and Peru, could also produce more heavy crude in the future.

The production outlook for the major heavy crude producing areas is shown in the table. The forecast is premised on the following predicted developments:

- Venezuelan heavy crude activity will continue to expand, facilitated by foreign involvement in large upgrading projects in the Orinoco oil belt, but low oil prices will slow these projects over the next several years.

- Mexico's development plans will be limited by low oil prices.

- Canada's bitumen output growth will slow until after 2000, as lower crude prices discourage development of additional crude production.

- Cuts in Organization of Petroleum Exporting Countries quotas will limit heavy crude production from the Middle East.

- California production will decline, especially from the Outer Continental Shelf.

Canadian production

Conventional heavy crude and bitumen production recently experienced a period of very rapid growth. In 1995, production of conventional crude and bitumen averaged, respectively, 466,000 b/d and 149,000 b/d.Conventional heavy crude production averaged 543,000 b/d in 1998, an increase of nearly 17% since 1995. Bitumen production gains over the same period were more than 90%, to an average of 284,000 b/d in 1998. The trends have been made possible by advances in production technology, notably horizontal drilling and steam-assisted gravity drainage (SAGD).

In addition, a new bitumen production area at Wabasca-Pelican Lake, Alta., has shown substantial promise, and pipeline access is now available there. The bitumen produced in this area is lighter than Athabasca and Cold Lake sources, so its production cost is lower.

Also supporting growth in Canada's heavy oil output in recent years were price factors. The economics of heavy crude production were enhanced by a period of strong crude prices and relatively narrow light-heavy differentials.

Total Canadian crude oil production is expected to increase, to 2.9 million b/d in 2005 from about 2.2 million b/d in 2000 (Fig. 2 [55,952 bytes]).

Upgrading bitumen and heavy crude to produce light synthetic crude is an important route for expanding conventional heavy crude and bitumen markets. Expansion plans have been announced for the oilsands plants and field upgraders in Western Canada (see related article, p. 22).

Increasing production of synthetic crude from these expansions will replace declining conventional light crude. Frontier production, mainly East Coast light crude, will also continue to increase.

While Canada's heavy oil output is expected to decline slightly in the near term, production will resume its increase shortly after 2000. Increased production will provide feedstock for the expanded Lloydminster Upgrader. (Husky Oil Ltd. is planning to complete a $500 million expansion of the upgrader, increasing the plant capacity to 150,000 b/d from 69,000 b/d.)

The start-up of the proposed Shell Canada Ltd. Muskeg River mining and upgrading project would further increase bitumen production before 2005 (Fig. 3 [56,995 bytes]). Other companies, such as Mobil Oil Canada Ltd. and Koch Oil Sands LP, are assessing the feasibility of large-scale bitumen production and/or upgrading projects. The forecast increases in bitumen production will offset declining supplies of conventional heavy crude.

Until late 1998, pipeline capacity constraints limited deliveries of heavy crude and bitumen blends to the highest-value export markets. In fact, the rapid run-up in crude production overwhelmed available pipeline capacity in 1997, leading to high levels of apportionment in the Interprovincial (now Enbridge Pipelines Inc.) pipeline system. At the same time, capacity on the Express system was limited by a pressure-reduction order for its downstream Platte Pipeline.

Current expansions now under way in the Enbridge system should provide adequate capacity for many years. Enbridge's Terrace Phase I expansion project will start up in 1999, increasing export capacity to the U.S. Midwest. It is expected that the Platte pressure-reduction order will soon be lifted, allowing higher deliveries of crude into the southern Petroleum Administration for Defense District (PADD) II region.

The availability of diluent is another factor that can affect heavy crude production. Supplies were in tight balance during 1997, a direct result of strong demand for heavy crude diluent. Pricing pressure on diluent led to several measures aimed at easing the balance of suitable hydrocarbon streams. Edmonton refiners, for example, were able to produce incremental naphtha for diluent use.

Incremental supplies of pentanes-plus are resulting from gas-directed drilling in Western Canada, while the demand for diluent is in decline, at least in the short term. Enbridge has instituted a higher viscosity limit for shipments in its system. No pressure on the balance between pentanes-plus and condensate is therefore expected before the middle of the next decade, leaving surplus supplies of condensate for refineries in Canada and the U.S.

U.S., Latin America output

U.S. Lower 48 crude production is in permanent decline, but Gulf of Mexico production is expected to increase through 2005. Most of the gulf production will be light, sour crude.The U.S. is a large producer of heavy crude, mainly from California. However, the outlook is for these supplies to decline sharply.

Latin American producers are Canada's most important competitors in the area of heavy oil production. Latin American heavy crude output and exports will increase substantially through the forecast period.

Venezuelan production and exports will be predominantly heavy and extra-heavy crudes. Joint venture projects in the Orinoco belt between the Venezuelan national oil company, Petroleos de Venezuela SA (Pdvsa), and foreign partners will contribute to new supplies of heavy and synthetic crudes (OGJ, Oct. 19, 1998, p. 49).

Under the terms of these agreements, upgrading of this heavy and extra-heavy production must be done in Venezuela. But most participants are strategically integrating the manufacturing of partially upgraded Orinoco extra-heavy crude with processing at Gulf Coast heavy crude refineries. Pdvsa is also pursuing a strategy of investing in Gulf Coast and Caribbean refining and conversion capacity through its Citgo Petroleum Corp. subsidiary.

Markets for Canada's crude

Major markets for Canadian crude are in Western Canada, Ontario, and the Northern Tier of the U.S.The northern states in PADD II (Midwest) comprise the largest export market region. The U.S. PADD IV (Rocky Mountains) is a smaller-but growing-export market region.

Canada's export pipeline capacity has been expanded through several projects, including start-up of the Express Pipeline in 1997 and expansion projects in the Enbridge system.

Western Canada and Ontario crude runs are predominantly light Canadian crude. However, Ontario refiners have imported a substantial volume of Gulf Coast and U.S. onshore crude since 1996.

The reversal of Enbridge's Line 9 in two stages this year will allow increased use of imported crude by Ontario refiners. The line was built in 1976 to carry Western Canada crude from Sarnia, Ont., to Montreal. Its reversal will displace Western Canadian light, sweet crude to the U.S. Midwest market.

At present, refiners in Western Canada and Ontario process about 170,000 b/d of domestic heavy crude. This volume should increase rather slowly until the start-up of Shell's Scotford upgrader around 2002.

Canadian crude exports are expected to decline through 2000 due to production cuts in Western Canada, but the dominant role of Canadian heavy crude in export markets will be unchanged.

Already, U.S. markets account for the majority of Canadian heavy crude disposition (Fig. 4 [56,826 bytes]). The largest market is in the Midwest region.

While partial upgrading options have received significant attention in Western Canada, the extent of upgrading and the markets for synthetic crude must be carefully considered. Integration of upgrading with refineries may be preferred for new large-scale bitumen projects. The recent period of low crude prices has delayed some announced projects, including Mobil's Kearl Lake mining-upgrading project.

PADD II refiners will continue to run Canadian crude as it is available, with Gulf Coast imports serving as the swing supply. However, the availability of pipeline capacity to deliver Latin American heavy crude to inland refineries is limited, because production in the Midcontinent region of PADD II has declined sharply in recent months, creating a greater need for imports. As a result, pipeline corridor flows from the Gulf Coast to the Midwest market are increasing and putting a strain on existing capacity.

Canada will serve as the prime supply source for heavy crude to the PADD II market (Fig. 5 [54,332 bytes]). Refineries in the southern Midwest (e.g., Wood River, Ill.) region have begun to process Canadian heavy crude on a year-round basis since the start-up of the Express Pipeline in 1997.

The rapid increase in Canadian heavy crude supply through 1996-97 resulted in displacement of other heavy crude to what may be considered a structural minimum level.

The availability of surplus Canadian heavy crude has prompted some Midwest refiners to add conversion capacity. Renewed federal funding for U.S. highway projects and more stringent asphalt specifications should contribute to stronger demand for Canadian heavy crude. Therefore, heavy crude runs in this region should increase, even though growth will be limited in the near term.

The recent curtailment of Canadian heavy crude production has led to shortfalls in PADD II. Projects such as the $235 million BP Amoco Toledo refinery conversion increase the processing capacity for heavy crude. This will lead to an even tighter regional balance. Increased use of imported heavy crude will likely occur until growth in Canadian production resumes, subject to pipeline capacity limits. Expansion of the Seaway pipeline (expected in the first quarter of 2000) should allow more imported crude to reach the Midwest.

The PADD IV market is expected to increase its processing of heavy crude. Due to the decline of indigenous production in the Rocky Mountain states, a growing dependence on Canadian crude is forecast. Increasing Canadian imports by PADD IV refiners will include more heavy crude.

Crude runs in PADD V, or the Western U.S., are predominantly light sour and heavy sour grades. The region's refining capacity is highly complex, particularly in California, where the production of cleaner refined products is mandated.

Refineries in PADD V have historically processed a significant amount of local production, which is light sour and heavy sour. Alaskan North Slope (light sour) production is declining, and should fall below 1 million b/d after 2000. California heavy crude production also continues to fall.

Sour crudes will continue to account for 90% of PADD V refinery runs through the forecast period. Therefore, PADD V will become more dependent on imported crude, and most of this will be sour.

Purvin & Gertz's analysis shows that Latin American crude will become an important supply source for the U.S. West Coast. Middle Eastern, Canadian, and Asian crudes will be imported on an opportunistic basis.

Crude price drivers

During 1997, markets remained strong despite a growing oversupply of crude in the Atlantic Basin. At the same time, a deepening financial crisis in Asia was reducing demand in this previously rapidly growing area.In 1998, the combination of excess global crude supplies and the economic turmoil in Asia drove world crude prices to their lowest level in more than a decade. All Canadian crudes are generally priced in the U.S. inland market and were therefore pulled lower by these developments.

Rapidly declining U.S. onshore production has put pressure on the inland pipeline systems to supply imported crude. Purvin & Gertz monitors the competitive interface between Canadian and Gulf Coast crudes in the U.S. Midwest. Through the middle of the next decade, sweet synthetic crude supplies from Canada will seek outlets in this market. Stricter new sulfur regulations for U.S. gasoline could result in stronger demand for such supplies.

Price differentials between light and heavy crude in the Midwest have been highly volatile, with the differential expanding in 1996 and 1997. Differentials have narrowed since crude prices fell in late 1997 and are expected to remain narrow in the near term.

Midwest light-heavy crude differentials are expected to widen in unison with global benchmarks. Still, production will continue to fall through 2000, because netback prices are below producers' cost of production.

Light-heavy differentials are not expected to be sufficient to support investments in new conversion capacity at refineries in PADD II for several years. As a result, growth in this key market will be limited.

Canadian crude prices

Pricing for benchmark Canadian heavy crudes is established in relation to the delivered cost of marker crudes such as Maya, in the Midwest. Waterborne imported heavy crude is expensive in PADD II due to surcharges for high-viscosity shipments in the inland pipeline systems.In general, Canadian light-heavy crude price differentials track world benchmark differentials and should widen before 2003. A profitable level of differentials for refinery investment in heavy oil processing facilities should occur by that time.

Canadian markets are subject to unique regional factors. Oversupply of Canadian heavy crude during 1996 and 1997 resulted in a wider differential vs. the Gulf Coast, as prices were being set by deliveries to lower-valued markets on the West Coast. With curtailments in Canadian supply and strong demand for asphaltic crudes in the Midwest, differentials reversed course and narrowed sharply in 1998. Canadian heavy crude should remain in high demand in PADD II for new coking capacity and higher asphalt demand.

The average 1998 bitumen netback price of around $5/bbl was below the estimated full cost of production (including capital and operating costs) for even large-scale, low-cost producers (Fig. 6 [57,247 bytes]). Recent supply cuts have strengthened Canadian heavy crudes beyond price parity at Wood River.

The outlook through the early years of the next decade calls for narrow price discounts in the Midwest, as supply of Canadian heavy crude is limited by poor field netbacks.

Western Canadian prices for heavy crude oil are expected to recover over the next few years. Bitumen field netbacks in Canada are also forecast to improve steadily, based on strong Midwest demand and modest premiums for diluent supplies. By 2001, field prices are expected to recover to more than $8/bbl. Bow River is a conventional heavy crude benchmark. For comparison, its price at Hardisty, Alta., is likely to increase from about $10.00/bbl in 1998 to about $11.50/bbl in 2001.

These netback prices are considered sufficient to encourage further development of heavy oil and bitumen. The largely underdeveloped Athabasca region of Alberta will see more development. These developments are expected to be large-scale bitumen projects and, as is the case with the Shell project, will involve some form of upgrading.

Netback prices for Canadian heavy crudes will continue to be highest from the U.S. Midwest. Lower netback prices from the West Coast will limit Canadian deliveries there.

Crude conversion economics

Purvin & Gertz monitors a number of factors that influence the global resid supply-demand balance. These include crude production by type, light products demand, and conversion capacity availability. Global resid conversion capacity (excluding the U.S.) will continue to exceed estimated requirements through 2000, the result of a capacity build-up in response to the strong growth in products demand over the last decade. By the middle of the next decade, the rapid pace of demand growth will once again support conversion capacity expansions.U.S. conversion capacity surged in the early 1990s, with the need for environmentally driven fuels projects. Large projects, such as Trans-American Refining Corp.'s refinery start-up, will contribute to an overbuilding of conversion capacity through 2000.

Atmospheric bottoms (650° F.+) production has increased over the last 10 years, but bottoms as a percentage of crude declined during 1985-95. During the 1980s, a drop in bottoms content occurred, due to lower OPEC production. In the 1990s, light, sweet crude production has increased, with the North Sea as the main contributor to this trend.

Growing heavy crude production in Canada and Latin America reversed the decline in bottoms content beginning in 1996, but the recent drop in crude prices will again reduce the bottoms content to lower-than-historical levels. This will result in several years of narrow light-heavy price differentials.

Profitability of deep-conversion refineries reached exceptionally high values in 1991 during the Persian Gulf war but dropped to very low values in 1995. Margins recovered in 1996-97 and have remained at reasonable levels.Purvin & Gertz expects coking returns to stay at a level adequate to support moderate additions to conversion capacity. Incremental capital recovery factors for a light, sour refinery converting to coking are expected to be modest for the next several years, with some improvement seen shortly after 2000.

Reduced heavy crude supplies in 1999 and 2000 will result in poor coking returns. An increase in heavy oil production after 2000, largely from Vene- zuela, will cause the differential to widen once more. As always, a cycle is possible in this trend can be expected.

Longer term, the prices of Latin American heavy crudes will be set by their value in U.S. Gulf Coast cracking refineries, because the supply of Western Hemisphere heavy crude will exceed the capacity of existing coking refineries. The resulting light-heavy crude differential will widen to justify new upgrading facilities.

Conclusions

Purvin & Gertz has determined that the current environment for Canadian heavy crude markets suggests a slowdown in activity. For a short time, production may fall short of the demand by refiners in PADD II, the largest market for Canadian heavy oil, prompting narrower light-heavy differentials there.Many producers expect to increase crude production in the early part of the next decade, and this should restore traditional market supply relationships.

Canadian heavy crude competes with Latin American crude in the PADD II market. Heavy crude markets were limited through 1997 by available outlets, pipeline capacity constraints, and diluent supply, but are now facing security-of-supply concerns. Pipeline capacity constraints in the main delivery corridors feeding the U.S. Midwest are limiting the ability of these producers to supply the region. As a result, Canadian heavy crude may lose some market share to Latin American production in the near term.

Light-heavy differentials should support investments in conversion capacity only after 2005. At that time, benchmark crude oil prices are expected to be sufficient to encourage more heavy crude production. Growth in Canadian heavy oil production will depend heavily on a recovery in global crude prices, given its higher cost structure relative to competitive supply regions.

Once market growth for Canadian crude resumes, the traditional markets (primarily in PADD II) will continue to provide the highest netback price. No infrastructure limitations or diluent shortfalls are expected until well into the next decade.

PADD IV deliveries should also grow and provide the same netback price as PADD II.

The U.S. West Coast market is not likely to develop into a viable alternative for Canadian heavy crude. Despite the West Coast's growing need for imported supplies of light sour and heavy sour crude, the netback price for Canadian heavy from this region will remain substantially less than the netback from the traditional Midwest market. n

The Author

Steven J. Kelly is a principal in the Calgary office of Purvin & Gertz Inc. He joined the company in 1996 and provides crude oil and product market analyses for clients in Canada and the U.S. Midwest. Kelly began his career with Shell Canada Ltd. in 1984, after receiving bachelors and masters degrees in chemical engineering from McMaster University. He obtained an MBA from the University of Calgary in 1998.

Copyright 1999 Oil & Gas Journal. All Rights Reserved.