UBD creates wellbore instability in horizontal wells

Shiming He Wei Wang Ming Tang

Southwest Petroleum University, Chengdu

Ruifeng Zhang

PetroChina, Renqiu

Combining circumferential stresses with additional stresses produced by fluid seepage creates a new model which can be combined with the conventional model to fully describe in-situ stress regimes' influence on wellbore stability during underbalanced drilling (UBD) of horizontal wells.

This article finds the effects of in-situ stress regimes on wellbore stability by comparing them with a conventional model that does not take fluid seepage into consideration. It then demonstrates how fluid seepage creates greater wellbore instability and that different in-situ stress regimes impact wellbore stability in both models.

Conventional model limitations

Data demonstrating the impact of in-situ stresses in UBD of horizontal wells are often overlooked using conventional models.

Researchers have looked at the effects of in-situ stresses on the wellbore and, based on the data, conducted studies to reveal the mechanism of wellbore collapse during overbalanced drilling (OBD).1 2

Studies of UBD operations have established a coupled reservoir-geomechanics model that simulates the interaction between reservoir flow and deformation.3 The model can determine wellbore-stability design and sand-production risk evaluation in the formation during production or UBD.4 The model offers a practical technique to evaluate UBD of a horizontal well in a depleted reservoir.

The conventional model is limited, however, because it does not take into account fluid seepage.

Circumferential stresses

In-situ stress regimes fall into five categories: Normal faulting (NF) (δv> δH> δh), a regime between normal faulting stress and strike-slip stress (NF-SS) (δv=δH> δh), strike-slip stress (SS) (δH > δv> δh), a regime between strike-slip stress and reverse-faulting stress (SS-RF) (δH> δh=δv), and reverse-faulting stress (RF) (δH> δh> δv).5 6

In-situ stresses (vertical stress, δv; maximum horizontal stress, δH; and minimum horizontal stress, δh) ) are continuously acting on wellbore rocks during the drilling process as the wellbore changes from vertical to deviated and finally horizontal. Equation 1 expresses virgin formation stresses in the Cartesian coordinate (x, y, z),7 where i is the inclination angle in degrees and α is the relative azimuthal angle (an angle from the direction of maximum horizontal stress to the well axis measured in degrees).

Looking at the effects of in-situ stresses and effective fluid column pressure (Pmud) in the borehole, applying Equation 1's six stress components to the wellbore can determine the redistribution of circumferential stresses

Since the greatest concern for wellbore stability is at the borehole wall, stress components in Equation 1 at that location can be re-expressed by Equation 2 in the cylindrical coordinate (τ, θ, z), where θ is the angular position around the wellbore circumference measured in degrees and ν is Poisson's ratio.

From Equation 2, we find that δθ, δz, and τθ z are connected to θ, showing that the stress state of an inclined borehole varies with the spatial position of wellbore rocks. Because τθ z is usually not 0, whereas δθ and δz are not the principal stresses of wellbore rocks, δτ is a principal stress. Equation 3 shows the principal stress, δ, and shear stress, τ, consisting of the stress components in Equation 2.

When dδ/dβ = 0, another two principal stresses (δθmax and δθmin) emerge (Equation 4). Here the principle of effective stress is taken into account where αe is Biot's coeficient, and Pp is pore pressure, MPa.

Fluid seepage stresses

Compared with conventional overbalanced drilling, effective fluid column pressure is lower than the formation pressure during UBD, showing that formation fluid will flow into the wellbore and seepage force will be exerted on wellbore rocks during UBD operations in horizontal wells (Equation 5).

Researchers have already devised the model and boundary conditions to study the effects of fluid seepage on wellbore during UBD of horizontal wells.8

Building on this allows determination of additional stresses induced by fluid seepage (radial stress, δfr; tangential stress, δfθ; and axial stress, δfz). Equation 6, where R is the borehole radius, m; r is the radial distance from the center of wellbore to a point in the formation, m; Pop is the original pore pressure, MPa; and re is the radius of external boundary, m, shows the additional stresses.

At the wellbore wall (r=R), Equation 7 expresses the stress components (δfr, δfθ, δfz) produced by fluid seepage. The principal stresses on wellbore rocks are found by linear addition of Equation 4 and Equation 7, further described in Equation 8.9

Wellbore-collapse model

For an easier calculation, maximum principal stress, intermediate principal stress, and minimum principal stress are assumed to be δe θmax, δe θmin, and δer respectively, in Equation 8. Using the Mohr-Coulomb mathematical model (expressed in Equation 9, which considers the principle of effective stress) yields a new wellbore-collapse model where δe1 and δe3 denote effective maximum principal stress and effective minimum principal stress, MPa, and φ and C represent the internal friction angle of rock mass and the cohesion strength of rock, respectively. The conventional model can also be leveraged by using the Mohr-Coulomb model when maximum principal stress, intermediate principal stress, and minimum principal stress are δθmax, δθmin, and δr respectively, in Equation 4.

Model testing

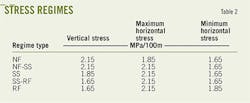

Data collected from a gas field in China where UBD of horizontal wells is ongoing tested the models. Table 1 lists rock mechanics data, well data, and in-situ stress data for the five stress regimes listed in Table 2. Both tables present the five stress regimes' (NF, NF-SS, SS, SS-RF, and RF) effects.

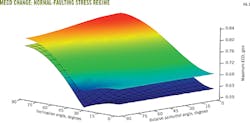

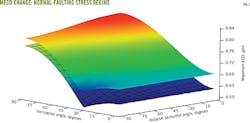

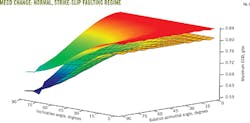

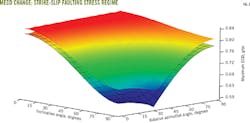

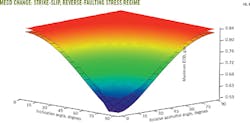

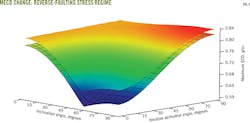

Figs. 1-5 show the maximum equivalent collapse density's (MECD) change with both inclination angles and relative azimuthal angles. MECD occurs at a certain inclination angle and relative azimuthal angle when θ changes from 0 to 90°.

The new model calculated the figures' smooth area, with the mesh area calculated by the conventional model.

The figures show that the changing trends of both models are the same, but MECD when fluid seepage is taken into account is greater than when it is ignored. The mud-weight window is also narrower and the wellbore is more unstable.

Fig. 1 shows the changing trend of MECD with inclination angles and relative azimuthal angles in the NF stress regime.

MECD increases with the increase of inclination angles and weakens with the increase of relative azimuthal angles for both the new model and the conventional model. The variation of MECD is sensitive to inclination angles.

When the inclination angle is fixed, the impact from the change of relative azimuthal angles on MECD is small. When drilling in the horizontal section of a well (i=90°), MECD is always large at a random relative azimuthal angle, showing that the wellbore is easier to collapse.

Fig. 2 illustrates the changing trend of MECD with inclination angles and relative azimuthal angles in the NF-SS regime. The horizontal section of the wellbore is most stable when it is drilled in the direction of minimum horizontal stress (α=90°) where the highest production rates are obtained.10

The wellbore is most unstable when the inclination angle is 0-45°. To keep the wellbore stable in the kick-off section, UBD should only be applied in the horizontal section.

Fig. 3 illustrates how MECD decreases with the increase of inclination angles in the SS stress regime when the relative azimuthal angle is random. MECD reaches the minimum value and the mud-weight window is the widest in the horizontal section.

Fig. 4 shows that MECD obtains maximum value when i=0° (vertical section) or α=90° in the SS-RF stress regime. The wellbore is most unstable at this time.

Fig. 5 indicates that MECD in the RF stress regime is much smaller at a higher inclination angle (i=60-90°) when it is drilled in the direction of maximum horizontal stress (α=0°).

The combined results of Figs. 3, 4, and 5 advise drilling at α=30-60° in the horizontal section to keep both a stable wellbore and high productivity.

Acknowledgments

The authors would like to acknowledge the support of the National Natural Science Foundation of China, Project No. 51474186, the 12th 5-Year Plan of China, Project No. 2011ZX05045-03-01WX, and the 11th 5-Year Plan of China, Project No. 2008ZX050450307HZ.

References

1. Zare-Reisabadi, M.R., Kaffash A., and Shadizadeh S.R., "Determination of optimal well trajectory during drilling and production based on borehole stability," International Journal of Rock Mechanics and Mining Sciences, Vol. 56, pp. 77-87, December 2012.

2. Aadnoy, B.S. and Hansen, A.K., "Bounds on in-situ stress magnitudes improve wellbore stability analyses," IADC/SPE Drilling Conference, Dallas, Mar. 2-4, 2004.

3. Wang, Y. and Lu, B., "A coupled reservoir-geomechanics model and applications to wellbore stability and sand prediction," SPE International Thermal Operations and Heavy Oil Symposium, Porlamar, Venezuela, Mar. 12-14, 2001.

4. Qiu, K., Gherryo, Y., Tan, C.P., and Marsden, R., "Underbalanced drilling of a horizontal well in depleted reservoir: A wellbore stability perspective," SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, Sept. 25-28, 2007.

5. Al-Ajmi, A.M. and Zimmerman, R.W., "A new well-path optimization model for increased mechanical borehole stability," Journal of Petroleum Science and Engineering, Vol. 69, No. 1-2, pp. 53-62, 2009.

6. Peng, S. and Zhang, J., "Engineering geology for underground rocks," Springer Science and Business, Berlin, 2007.

7. Fjaer, E., Holt, R.M., Horsrud, P., Raaen, A.M., and Risnes, R., "Petroleum related rock mechanics," Elsevier, Oxford, UK, 2008.

8. He, S.,Wang, W., Tang, M., Hu, B., and Xue, W., "Effects of fluid seepage on wellbore stability of horizontal wells drilled underbalanced," Journal of Natural Gas Science and Engineering, Vol. 21, pp. 338-347, November 2014.

9. He, S. Wang, W., Shen, H., Tang, M., Liang, H., and Lu, J., "Factors influencing wellbore stability during underbalanced drilling of horizontal wells-When fluid seepage is considered," Journal of Natural Gas Science and Engineering, Vol. 23, pp. 80-89, March 2015.

10. Rabaa, W.E., "Experimental study of hydraulic fracture geometry initiated from horizontal wells," SPE Annual Technical Conference and Exhibition, San Antonio, Oct. 8-11, 1989.

The authors

Shiming He ([email protected]) is a professor at Southwest Petroleum University of China and the vice director of the Oil and Gas Well Drilling Technology Center at Southwest Petroleum University, Chengdu. He specializes in underbalanced drilling, wellbore stability, well control, and other areas concerning drilling technologies. He holds a PhD in oil and gas drilling technology from Southwest Petroleum University.

Wei Wang ([email protected]) is a postgraduate student at the State Key Laboratory of Oil & Gas Reservoir Geology and Exploitation, Southwest Petroleum University of China, Chengdu. Wang's focus is on wellbore stability and underbalanced drilling. He holds a BA in petroleum engineering from Southwest Petroleum University.

Ming Tang ([email protected]) is a doctoral student at the State Key Laboratory of Oil & Gas Reservoir Geology and Exploitation, Southwest Petroleum University of China, Chengdu, and a visiting professor at the Mewbourne School of Petroleum and Geological Engineering at The University of Oklahoma, Norman. He holds an MA in oil and gas well drilling engineering from Southwest Petroleum University.

Ruifeng Zhang ([email protected]) manages the department of exploration at Huabei Oil Field Co., PetroChina. He holds a PhD in petroleum engineering from the Chinese Academy of Geological Sciences, Beijing.