Tarek Saba

Exponent Inc.

Maynard, Mass.

While some produced waters from the Marcellus shale contain elevated radium, a Pennsylvania Department of Environmental Protection (PA DEP) study showed that the risk of exposure is low. When treating of produced water is needed, technologies are available to reduce the volume of naturally occurring radioactive material (NORM)-containing filter cake and its disposal cost.

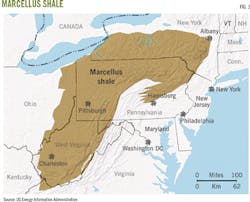

During 2013-14, PA DEP conducted a study of NORM in Marcellus shale natural gas operations (Fig. 1).

This study, called the most comprehensive ever by PA DEP secretary Mike Krancer, came on the heels of US Geological Survey (USGS) studies conducted in New York and Pennsylvania that found variable levels of radium with an upper limit exceeding the US Environmental Protection Agency (EPA) drinking water standard.1 2

PA DEP released the findings of its study in January 2015. This article will review PA DEP’s results, look at the reasons for the interest in NORM as it pertains to oil and gas operations, and highlight the ongoing research into NORM treatment.

What is NORM?

Understanding interest in NORM requires review of some basic chemistry. Unstable atoms, called radionuclides have an excess number of neutrons and protons. To stabilize, they eject either the excess particles, electromagnetic energy, or both.

Radium (Ra), an unstable atom and an example of a NORM, was of interest to the PA DEP.

Radium has several isotopes, or versions of atoms, in nature. All have the same number of protons and electrons, 88, which uniquely identifies the element. Each, however, has a different number of neutrons and atomic mass. Ra-226, for example, has 138 neutrons (88 protons + 138 neutrons = atomic mass number of 226).

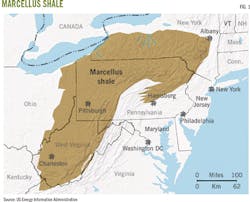

Ra-226 stabilizes by ejecting from its nucleus an alpha particle composed of two protons and two neutrons. In the process, Ra-226 changes to radon-222 (Rn-222), a radioactive gas that has 86 protons in its nucleus (Fig. 2).

The decay of half Ra-226’s atoms, its half-life, is 1,622 years. The daughter product, Rn-222, has a much shorter half-life,3.8 days.

Unlike Ra-226, Ra-228 decays by ejecting a negatively charged beta particle from its nucleus. In this decay, a neutron is split into a proton, an electron (the beta particle), and a neutrally charged particle. The half-life for Ra-228 is 6.7 years.

Radioactivity is expressed in curies (Ci). One Ci is equal to 37-billion disintegrations/sec. In water samples, such as produced water, a common unit of measurement for radioactivity is picocuries per liter (pCi/l). The EPA drinking-water standard for the combined activity of Ra-226 and Ra-228 is 5 pCi/l.

NORM in produced water

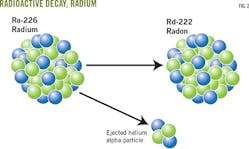

A 2011 USGS study found that radium was present in water produced from hydraulically fractured gas wells in the Marcellus shale. Radium levels in some samples were orders of magnitude higher than the industrial effluent level of 60 pCi/L (Fig. 3).1

The author was involved in studies that chemically characterized produced waters from Marcellus shale gas wells parallel to the USGC study. Our results were similar.

The presence of NORM in some produced waters opened the door for speculative discussions about the potential for exposure to radioactive material in natural gas production.

This occurred even though data collected from industry practices did not indicate such a risk. In response, PA DEP launched its NORM study to understand any potential long-term risks.

PA DEP study findings

Earlier this year PA DEP released its findings detailing the risk of human exposure to “technologically enhanced naturally occurring radioactive” material (TENORM) and the potential pathways by which such exposure might occur.

The report was based on data collected between June 2013 and July 2014 from well sites, three types of wastewater treatment plants, landfills, gas storage and distribution sites, end-use facilities, and roads treated with gas-well brine.

Data consisted of radiological screening surveys, as well as solid, liquid, and gas samples analyzed for radioactive material. Water samples from well sites, wastewater treatment plants, and landfill leachates were analyzed for radioactive elements, including radium, uranium, and thorium. The same radioactive elements were analyzed in solid samples, such as soil, drill cuttings, and filter cake. Air samples were analyzed for radon.3

The report concluded that the public faces little potential for radiation exposure above background levels from natural gas in homes, driving on roads treated with gas-well brine, or living near active gas wells.

There is also little potential for additional radiation exposure to oil and gas workers at active wells, storage and distribution centers, landfills, or in the transportation of oil and gas waste.

In all cases, the expected yearly dose was below the maximum allowed for non-radiation workers, although the actual dose experienced depended on many factors for which the study could not control, particularly percent of time a worker spends in high versus low-radiation areas of a given site.

Although the report found that risk of exposure to TENORM is low, it suggested that radiological-environmental impacts could be important. Spills of filter cake and wastewater could contaminate soils, for example. The report recommended routine radiation surveys for sites like wastewater treatment plants and landfills.

Treating produced water

Elevated radium levels in produced water may pose challenges if treatment is necessary for water reuse in drilling of new gas wells or to make road salt. Treatments may result in the precipitation of dissolved solids and the formation of sludge or filter cake.

The presence of elevated radium may result in sludge with concentrations greater than 25 pCi/g. This would make the sludge ineligible for disposal in a non-hazardous landfill, increasing disposal cost.

In 2012, General Electric Global Research Center conducted research on produced water for a contractor to the US Department of Energy (DOE),4 seeking to develop technology to recover distilled water and salable road salt from produced water by producing sludge containing less than 25 pCi/g radium concentration thereby reducing disposal cost. Through multiple trials, GE concluded that a treatment system of modified lime-soda softening would be most economical, maximizing the proportion of sludge that could be disposed of in a non-hazardous facility.

References

1. “Radium content of oil and gas field produced waters in the northern Appalachian Basin (USA): Summary and discussion of data,” US Geological Survey, Scientific Investigations Report 5135, 2011.

2. “Radon-222 content of natural gas samples from Upper and Middle Devonian sandstone and shale reservoirs in Pennsylvania: Preliminary data,” US Geological Survey, Open-File Report Series 1159, 2012.

3. “Technologically Enhanced Naturally Occurring Radioactive Materials (TENORM) Study,” Pennsylvania Department of Environmental Protection, Jan. 15, 2015.

4. “Produced water pretreatment for water recovery and salt production,” General Electric Global Research Center, Jan. 26, 2012.

The author