China accelerates shale gas development

Zhao Jinzhou

Yang Hai

Li Yongming

Liao Tao

Southwest Petroleum University

Chengdu City

China

China began tapping into its shale gas resources as early as 1996 (Table 1). But after a 2014 government report proposed that the nation "speed up the exploration and development of shale gas resources," the revolution is getting into full swing.1

There are several shale plays to exploit in China. Marine plays are located in south China, north China, and the Tarim basin. Continental shales are distributed over the Songliao basin, the Ordos basin, Bohai Bay, the Turpan-Hami basin, and the Junggar basin. Transitional shales are located in northern part of China(Fig. 1).2 Table 3 lists the characteristics of these shale plays.3

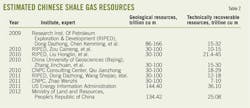

According to resource-prediction models from a number of institutions,3 China's total shale gas geological resources range 30-166 trillion cu m, while technically recoverable reserves are 7-45 trillion cu m (Table 2). These estimates are expected to rise with the development of new and existing technologies. To get an accurate assessment of technically recoverable shale gas resources, China will invest $4 billion to conduct a nationwide survey of shale gas resources during 2013-20.

As of April, more than $2.45 billion has been invested in shale development. These monies have led to 322 completed shale gas wells, including 108 vertical investigation wells, 118 exploration wells, and 96 horizontal appraisal wells.

In terms of production, 38 of the wells (18 vertical and 20 horizontal) are each generating more than 10,000 cu m/ day (about 353 Mcfd), and 23 wells of the 38 (3 vertical and 20 horizontal) are each producing more than 100,000 cu m/ day.4 In total, China's shale gas output in 2013 was 200 million cu m.

The shale gas reserve of the Fuling district, owned by the Jianghan Oilfield branch of Sinopec International Petroleum Exploration & Production Co., has been proven at 2.1 trillion cu m. The shale gas output in Fuling was 0.36 billion cu m through April of this year, and 0.342 billion cu m has been sold.

In March, Sinopec announced that the output of the Fuling shale gas plays is expected to climb to 5 billion cu m/year by 2015 and 10 billion cu m by 2017-the equivalent of a large oil field with an output of 10 million tonnes (about 73.3 million bbl)/year of oil.

New equipment and operation systems have been used in Fuling, such as train-type drilling rigs, operation-line work, and repeated use of fluids. These measures not only reduced costs, but also shortened drilling time to about 70 days from 100.5

Fuling's production is approaching 3 million cu m/day with significant increases from specific wells. The cumulative production of Well Jiaoye-1HF has hit 28 million cu m/year since the beginning of 2013 and is expected to produce 0.117 billion cu m during its lifespan. Additionally, production of Well Jiaoye 8-2HF and Well Jiaoye 13-2HF is more than 0.2 million cu m/day each.5

Technologies, tools, equipment

The US shale gas boom is enabled by advances in horizontal drilling and hydraulic fracturing technologies. Similar advances are fueling China's growth, as well.

Sinopec has developed an elastic-plastic cement-slurry system, pad fluids system, and relevant additives, which can be applied to low-pressure, leaky, long horizontal shale gas wells. They are also suitable to high-temperature, high-pressure conditions.6

The working pressure of equipment developed in China such as fracturing trucks, sand-mixing trucks, manifold trucks, and smart-measuring trucks has reached 140 MPa (about 20,000 psi).7

In April, China's deepest horizontal shale gas well, Nanye 1HF in Chongqing, was successfully stimulated with 15 stages and 755 cu m of sand with such trucks. The deviated depth and vertical depth were 5,820 m and 4,627 m (about 19,000 ft and 15,200 ft), respectively, and the length of the horizontal section was 1,053 m. The closure pressure reached 109 MPa (Fig. 2).8

Some major breakthroughs in Chinese shale gas technology include:

• Flowback reuse. A large amount of water is necessary for shale gas fracturing and China National Petroleum Corp. (CNPC) has committed to reusing flowback better.

In Changning fracturing treatments, 13,000 cu m of fracturing-fluid flowback from well pad H3 was reused in 56 fracturing stages of four wells on well pad H2. That means that 13% of the total water consumption of the wells was replaced by recycled fluids.

Chemical and physical methods were used in the fracturing-fluid treatment. Molecular- reconstruction using guar gum to offset the side effects of residual gel breaker on the second cross-linking reaction.9

• Temporary plugging, volume-fracturing. Based on the stress profile, the length of each fracturing stage is designed from 200-500 m. In each stage, the first hydraulic fracture is created at the most favorable area as determined by fluid pressure.

Then, a grainy, high-strength, water-soluble, temporary plugging agent is used. This type of agent can withstand pressure as high as 80 MPa and is made from the cross-linking reaction and potential energy acting together under high pressures and temperatures.

Once the first hydraulic fracture is plugged, the pressure continues to rise until the second favorable hydraulic fracture is created in the same way. Five hydraulic fractures are generally created with this method.

The in situ monitoring data showed that in the 400-m stage, four fractures were created within 120 m but none in the remaining 280 m. That meant that 70% of the fracturing fluids would have been wasted if a conventional-length fracturing stage had been created.

Powdered, high-strength, water-soluble temporary plugging agents should be applied to plug the tips of each hydraulic fracture to make them turn to a different propagation direction.

Once the fracture-propagation direction is changed, the tip-plugging agent vanishes and the fracture propagates along its original direction. Continue to plug the tip to turn the fracture.

Many branches and microfractures are created along the main hydraulic fracture forming a complex fracture network (Fig. 3). Through this network, the stimulated-reservoir volume can be broadened. This technology also can minimize the use of downhole tools, reducing the risk of incidents. 10 11

Five shale gas wells, Jiaoye 8-2HF, Jiaoye 1-2HF, Jiaoye 7-2HF, Jiaoye 9-2HF, and Jioaye 13-2HF, were stimulated with this new fracturing technology.

On average, 5,000 cu m of fluids were saved for each well compared with conventional multistage fracturing technology.10

Currently, China imports the biodegradable, high-strength, temperature-resistant plugging agent used in shale gas plays such as these. Domestic agents cannot be used to create new fractures due to their insufficient compressive strength.

The price of a moderate-temperature, high-strength plugging agent is 1.6 million RMB Yuan (about $260,000)/tonne. Based on China's shale gas pilot tests, it takes about 1.5 tonnes of plugging agent in 1,500 m of horizontal section of a shale gas well.

Given the planned expansion of shale gas exploitation, Chinese demand for high-strength, temperature-resistant plugging agents will increase greatly in coming years.

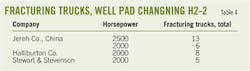

• Four-well simultaneous zipper fracturing technology: In March 2014, the first pilot test of a four-well simultaneous-zipper-fracturing treatment was conducted in Changning's well pad H2-2.

This operation injected about 120,000 tonnes of fracturing fluid and 5,500 tonnes of sand into the cumulative 56 fracturing stages, using 32 fracturing trucks-70% of which were developed in China (Table 4).

Shortly after injection, Well Jiaoye 9-1HF and Well Jiaoye 9-3HF were stimulated successfully through zipper fracturing with 37 fracturing stages, 2,090 cu m of sand, and 62,165 cu m of fluid.6

• Logging technology for deep shale gas wells. An advanced-memory, cement-bonding, variable-density log (CBL/VDL) was developed in China. This was used to obtain accurate logging data for Well Nanye1HF with a depth of 5,820 m, a 1,053 m horizontal section, and small bore size.6

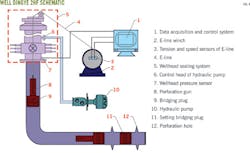

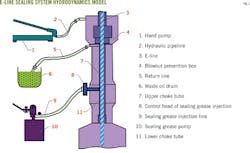

• Combining perforation and multistage fracturing using E-line and drillable bridging plugs for deep shale gas wells. This technique was used to stimulate independently a shale gas well (Dingye 2HF) with a complex geological structure, various pressure systems, high temperature (146° C., or about 298.4° F.), high pressure (138 MPa), and high hydrogen sulfide volume.

The E-line transported and controlled the plugs and perforation tools to favorable positions in the well at a depth of 5,700 m, in a 1,690-m horizontal section.

This stimulation injected 29,521 cu m of fluid into the well and 319 cu m of sand into 12 fracturing stages. Fig. 4 gives the schematic diagram of the well, and Fig. 5 illustrates the hydrodynamic model of the E-line sealing system used in the operation.12

• Combining composite-bridge plugs and multi-cluster perforation. The composite bridge plug is a critical tool in shale gas stimulation. Southwest Oil & Gas Field Co. of CNPC has developed and applied a composite bridge plugging and multicluster perforation to several wells.

Among these, the maximum depth and horizontal section were 4,890 m and 1,549 m, respectively, the maximum working pressure reached 98 MPa while the temperature was 116° C.

According to field data, the duration of plug-drilling averaged 26.8 min. In well Y101-78-H1, there were 9 plugs and 10 fracturing stages reached, and its gas production was more than 60,000 cu m/day.9

Chuanqing Drilling Engineering Co. has developed a series of multicluster perforation techniques, including multiple-ignition technology, a drillable composite plug, advanced perforation guns, horizontal transportation, and an E-line wellhead-blowout preventer. Twenty ignition stages of each operation can be reached with the E-line system.

Currently, the longest horizontal section stimulated with multi-cluster perforation technique was 2,099 m, and there were 69 perforation clusters.9

• Rotary navigation drilling systems. RNDS are an essential technology for extended-reach horizontal wells and directional ultradeep wells under complex geological conditions.

An RNDS developed by Chuanqing Drilling Engineering Co. was tested in Well 022-H3 in November 2013. It features surface monitoring and bidirectional communication, as well as a drilling-measurement system and downhole rotary navigation.9

• High-horsepower fracturing trucks. Fracturing scale is always restricted by the power of fracturing trucks. In China, the horsepower output has climbed to 4,500 hp.

Some trucks have been developed specially for pad fracturing in rough terrain. For example, a truck with 3,100 hp was produced to tackle hills, mountains, deserts, and other difficult operating conditions.8

• Drilling fluids for shale gas wells. In China, oil-based drilling fluids are preferred. The oil-based drilling-fluid system for directional and horizontal sections of Well Wei 201-H3 included diesel oil, 3.5% organic clay, 10% calcium chloride, 4-6% main emulsifier, 1-2% auxiliary emulsifier, 2-3% filtrate reducer, 1-3% elastic-plugging agent, .5-1% weighting agents, 1-2% of 0.043 mm-diameter calcium carbonate, 2-3% 0.03 mm-diameter calcium carbonate, 1-1.5% calcium oxide, and barite.

This drilling fluid system successfully prevented the collapse of shale layers during drilling.13

China's shale gas future

China's 5-year plan for shale gas had been to increase production to 6.5 billion cu m/ year by 2015. The technological advances listed above, however, have put the country ahead of schedule.

In April of this year, 32 drilling platforms and 130 wells had been completed in the town of Jiaoshi in Fuling district. Sinopec expects to drill 100 new shale gas wells in total this year, with 42 total platforms.

Shale gas production should reach 12-13 billion cu m/year by 2015, double the planned production.

About 10 billion cu m of this will be contributed by Sinopec and CNPC. The rest will come from China National Offshore Oil Co. (CNOOC), Yanchang Oil Co., China Huadian Corp., China United Coalbed Methane Corp., and a few private companies.

Based on data releasesed by the Ministry of Land and Resources in June, 72% of shale gas has come from Sinopec, 21% from CNPC, and 7% from Yangchang Oil Co.

CNPC plans to advance the shale gas productivity of Chongqing to 0.7 billion cu m/year by yearend 2017 and 4.5 billion cu m/year by 2020.14

There is a long way to go to meet these goals. Although some pilot shale gas activities have been conducted in China, core theories and techniques have not been mastered yet. It will take more than just technology, a fact that led the National Energy Administration to downgrade the country's output over the next 5 years.

For example, it is critical to enhance and control the stimulated reservoir volume. This includes predicting fracability in shale plays, understanding the mechanism of interaction between hydraulic and natural fractures, and leveraging fracture-network-propagation theory.

China must also focus on the shale-gas-productivity-prediction theory, including the mechanism of fluid flow in a fracture network.

China still needs to master pad fracing, single-well alternate fracturing, waterless fracturing, and other new techniques. For example, air-driving fracturing, which is a high-energy, thermal-mechanical, coupled-air-fracturing technology that can be used to make shale rock brittle for better fracturing.15

Infrastructure is also critical and China is already addressing this need. The total length of oil and gas pipelines reached 106,000 km (about 65,850 miles) by yearend 2013. Natural gas pipeline will reach 93,000 km by 2015, and the total length of existing oil and gas pipelines is expected to increase to 150,000 km by 2020.16

Currently, 90% of natural gas pipelines are controlled by CNPC.17 CNPC, however, is about to sell billions of RMB Yuan in pipeline assets which will help enhance efficiency.

References

1. Dong, D.Z., Zou, C.N., and Yang, H., et al., "Progress and prospects of shale gas exploration and development in China," Acta Petrolei Sinica, Vol. 33 (2012), S.1, pp. 107-114.

2. Zou, C.N., Dong, D.Z., Wang, S.J., et al., "Geological characteristics, formation mechanism and resource potential of shale gas in China," Petroleum Exploitation and Development, Vol. 37 (2010), No. 6, pp. 641-653.

3. Zou, C.N., Dong D.Z., Yang, H. et al., "Conditions of Shale gas accumulation and exploration practices in China," Natural Gas Industry, Vol. 31 (2011, No. 12, pp.26-39.

4. Lv, Jia, "China shale gas exploration and exploitation activities are going well," www.gov.cn.

5. Bai, Lin, "Chongqing: Shale gas output is approaching 3 million cu m per day," www.gov.cn.

6. China Petrochemical News, enews.sinopecnews.com.cn.

7. Science and Technology Agency of Liaoning Province, www.lninfo.gov.cn.

8. China Shale Gas News, www.csgcn.com.cn.

9. News of China National Petroleum Corp., news.cnpc.com.cn.10. Xinhua News; news.xinhuanet.com.

11. Oil & Gas Survey of China Geological Survey, www.ogs-cgs.cn.

12. Zhu, Xiuxing, Xue, Shifeng, and Tong, Xinghua, "Parameter control methods for the pumping tool-string composed of perforating gun and fracturing plug in a horizontal well," Petroleum Exploration and Exploitation, Vol. 40 (2013), No. 2, pp. 371-376.

13. He, Tao, Li, Maosen, Yang, Lanping, et al., "Application of oil-based drilling fluid in shale gas horizontal well in district of Weiyuan," Drilling Fluid & Completion Fluid, Vol. 29 (2011), No. 3, pp. 1-5.

14. Bai, Lin, "CNPC is accelerating the pace for shale gas development in Chongqing," www.gov.cn.

15. Xie, Heping, Gao, Feng, Ju, Yang, et al., "Unconventional theories and strategies for fracturing treatments of shale gas strat," Journal of Sichuan University (Engineering science edition), Vol. 44 (2012), No. 6, pp 1-6.

16. ChinaNews, "China's oil and gas pipelines reached 106 thousands km," finance.chinanews.com.

17. Robot, "Thinking on the national pipeline company," finance.ifeng.com.

The authors

Zhao Jinzhou([email protected]) is president of Southwest Petroleum University (SWPU) and a researcher in State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation of SWPU in Chengdu, China. He holds an MS in oil and gas reservoir exploitation engineering from SWPU. He directs the China Petroleum Education Society and Chinese Society of Petroleum Graduate Education and is a member of National Technical Committee of Oil and Gas Reservoir Exploitation and Society of Petroleum Engineers.

Yang Hai([email protected]) is a PhD candidate of Southwest Petroleum University at State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation, Chengdu.

Li Yongming([email protected]) is a professor of SWPU at State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation of SWPU. He holds a PhD from SWPU.

Liao Tao([email protected]) is a PhD candidate of Southwest Petroleum University at State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation of SWPU, Chengdu.