Transferred geothermal energy heats wellbore

Shaobin Hu

Lingling Guo

Yongjian Liu

Northeast Petroleum University

Daqing, China

Theoretical calculations and laboratory experiments have demonstrated the feasibility of heat transfer with a sucker rod string. Liaohe field tests of the wells show this technology can heat the wellbore in steam-stimulated wells.

Fluid produced from heavy or high-wax oil wells exhibits sharply increasing viscosity and flow resistance rates because of heat loss as it flows from bottomhole to wellhead. Wax precipitation often causes stranded or blocked fluids near the wellhead, which overload the pumping unit and restrict the normal oil well production.

One means of addressing this problem is to heat the produced fluid, with either electrical or hot-fluid circulation. This solution, however, increases energy consumption and operating costs and complicates downhole operations.

This article proposes a new wellbore heating technology in which a hollow sucker rod is converted into a gravity heat pipe to absorb and transfer geothermal energy to heat the upper wellbore.

Technical principle

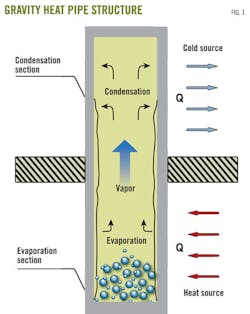

The new wellbore heating method is based on the functioning of a gravity heat pipe (Fig. 1) but adapted to use a hollow sucker rod string. A typical heat pipe is a cylindrical container that has been evacuated, injected with a certain amount of working fluid, and sealed. If one end of the pipe is heated and the other end is cooled, fluid separation occurs in the middle and two-phase heat transfer occurs.

In the heated section, the working fluid will boil and evaporate, changing phase from liquid to vapor and absorbing the latent heat of vaporization. The generated vapor will flow under pressure to the cooled section where it condenses as it encounters the cold wall, releasing the latent heat and passing it to the cold source outside of the wall. The condensed liquid will reflux under gravity and repeat evaporation and condensation. A typical heat-pipe principle can be used in oilwell pumping without changing the existing mechanical pumping.

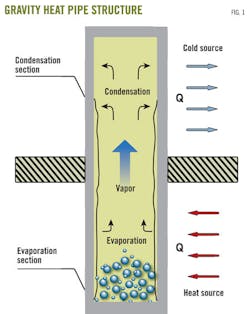

In the new method, a hollow sucker rod string is converted to a special heat pipe by cleaning the rod internally, filling it with working fluid, and sealing the connection. Fig. 2 shows it can transfer heat from the bottom to the wellhead. The continuous upward outflow of the produced fluid (oil or water) in the tubing provides both heat and cold.

In the lower wellbore, the high-temperature produced fluid provides the heat for the heat pipe, passing from produced fluid to heat pipe. In the upper wellbore, the temperature of the produced fluid gradually becomes cooler than the working fluid in the heat pipe. Heat transfers from the heat pipe to the produced fluids. The working fluid in the heat pipe constantly circulates and passes heat from the bottom of the well to the wellhead. The heat-pipe rod string is structurally simple and easy to operate; this low-cost, maintenance-free system automatically uses geothermal resources.

Prefeasibility study

Although a gravity heat-pipe sucker rod string has the characteristics of a heat pipe and works in accordance with the principle of phase-change heat transfer, the structures of a heat-pipe rod string and a typical gravity heat pipe differ. A heat-pipe rod string has a smaller inner diameter (less than 30 mm), but it may be hundreds or thousands of meters long.

For a long heat pipe, three aspects must be considered:

1. If the liquid pool is too deep, the heat pipe may lose boiling conditions.

2. If it has a high vapor flow rate and a small diameter, the flow may encounter a barrier because of entrainment.

3. With a long flow distance and large resistance, the vapor in the heat pipe may not flow to the end.

A successful evaluation of the process must consider the assembly, application, and working fluid. A prefeasibility study of the heat-pipe rod string1 2 provided insights into the process.

The heat-transfer calculation results with typical data show that heat transferred by the heat-pipe rod string accounts for 25-30% of the entrance enthalpy of the pumped fluid. This represents about 80% of the amount of heat dissipation from the fluid to the formation. Compared with ordinary sucker rod wells, the outlet temperature of the produced fluid of the wells using the heat-pipe sucker rod increased by 8-10° C.

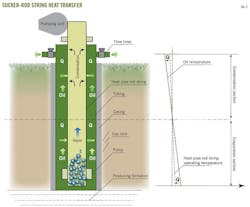

A comparison of the physical parameters, boiling condition, vapor flow resistance, and entrainment limit show that the performance of Solution A is better than water and that it can be used as the working fluid for the heat-pipe sucker rod string. Table 1 shows the working fluid's physical parameters.

Based on the underground working conditions, the experimental device shown in Fig. 3 was designed and built to perform the heat-pipe rod string heat-transfer experiment. The results of the laboratory heat-transfer experiments show that Solution A outperforms water and does not result in blockage or a large pressure drop.

The optimal amount of working fluid is 20% of the internal volume of the heat pipe. The ratio of the temperature of the condensation section and the evaporation section of the heat pipe is greater than 0.7. It is feasible to improve the wellbore temperature by using the heat-pipe rod string. A gravity heat-pipe rod string can be generalized to the oilfield.

On site assembly

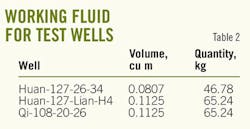

Three wells of the Liaohe oilfield (Huan-127-26-34, Huan-127-Lian-H4, and Qi-108-20-26) provide examples of the on site assembly process used to construct an ultralong heat-pipe rod string.

The hollow sucker rod selected was the KGW36-60DZ, produced by General Machinery Plant of Liaohe Petroleum Exploration Bureau. This sucker rod has a 36 mm OD, a 25 mm ID, and a 5.5 mm WT.

For the Huan-127-26-34 well, the pump is linked to a depth of 780 m, and the length of the hollow sucker rods is 770 m. The rod length is 8 m; consequently, 96 hollow sucker rods and 1 hollow polished rod are needed. The Huan-127-Lian-H4 and Qi-108-20-26 wells each requires 133 hollow rods.

Solution A, developed by Northeast Petroleum University, was the working fluid. The filling ratio is 10-20% (Table 2).

The equipment needed to assemble the gravity-heat-pipe rod string on site includes a rod top-sealing connecting device, working-fluid injection device, and vacuum pump. The rod top-sealing connecting device includes special valves, stainless steel pipe, stainless steel tee, and stainless steel adjustable joints.

The working-fluid injection device includes a metering pump, storage tank, pressure gauge, and pressure hose. The pumping rate of the vacuum pump should be 2 1./sec with an ultimate degree of vacuum of 0.06 Pa.

The accompanying box provides the assembly process.

Field application, effect analysis

The technology of wellbore heating by geothermal absorbtion with a gravity-heat-pipe sucker rod string was applied on three steam-stimulated wells in the Liaohe oilfield. This was the first time that the gravity heat pipe was assembled and tested on site with a non-water working fluid. After the heat-pipe technology was applied, the average wellhead temperature increase of the three wells was 10° C. This temperature improvement extends the normal production time and increases oil production.

Table 3 provides an overview of the test wells. Before application of the heat-pipe technology, viscosity-reduction measures (electric heating or hot-fluid circulation) were used to produce the wells.

During the Huan-127-26-34 well's test cycle, the well produced for 191 days, and the effective working time of the heat-pipe rod string (wellhead temperature of more than 51° C.) was 155 days. In the Huan-12-Lian-H4 and Qi-108-20-26 wells' test cycles, the average wellhead temperature was 10° C. greater than that of the previous cycle.

The Huan-127-26-34 well is an example for additional analysis and discussion.

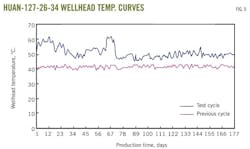

In the Huan-127-26-34 well, the average temperature of produced fluid at the wellhead was 41° C. in a previous cycle; in the test cycle, it was 51° C. Fig. 5 and Table 4 show that the wellhead appears to be stable with a sustained higher temperature, proving that the rod string functions as a gravity heat pipe to absorb geothermal energy to heat the borehole.

The continuous high temperature at the wellhead shows that the special heat pipe can start and maintain a good working status under the well's test conditions, transferring heat from the bottom to the wellhead. The technical parameters presented and the on site assembly process tested are feasible. Low-cost oil production can be achieved on steam-stimulated wells with the self-balancing geothermal absorption of the heat pipe to heat the wellbore without additional energy consumption.

Influencing factors

The gravity-heat-pipe rod string provides a new means of heating a wellbore; the influencing factors are complex, and many questions need further study. The primary influencing factors include the length of the rod string, reservoir temperature, fluid production rate, physical properties of the crude oil, and applicable conditions.

The lengths of the gravity-heat-pipe rod string for the Huan-127-26-34, Huan-127-Lian-H4, and Qi-108-20-26 test wells are 770 m, 1,000 m, and 1,000 m, respectively. The heat-transfer effect is not sensitive to length, and all heat pipes functioned normally, regardless of length. According to the heat-pipe suction limit theory, if the gravity heat pipe is placed vertically and the capillary force is ignored, the length of the gravity heat pipe does not stop the heat transfer; the test results confirmed this expectation.

The measured reservoir temperatures of the Huan-127-26-34, Huan-127-Lian-H4, and Qi-108-20-26 test wells are 99.74° C., 115° C., and 105° C. (at the depth of 830.09 m, 1,280 m, and 1,282.7 m), respectively. In accordance with the heat-pipe working principle and the working fluid used, the greater the temperature of the reservoir, the greater the energy transferred by the heat pipe. For reservoirs shallower than 1,300 m, maintaining the reservoir temperature at 100-120° C. by conventional steam injection (about 2,500 cu m) enables the heat pipe to start and work properly.

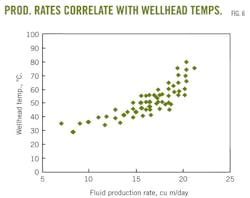

Fig. 6 shows the measured production rate and temperature of the produced fluid at the wellhead. At the determined condition, the greater the oil production rate, the higher the temperature of the produced fluid at the wellhead and the better the heat-transfer effect by the gravity-heat-pipe rod string. The outlet temperature increases of the produced fluid become more obvious when the fluid production rate is greater than 20 cu m/day.

As the well's production rate increases, the convective heat-transfer intensity of the fluid between the tubing and sucker rod increases longitudinally. The temperature of the upstream fluid in the tubing generally increases, which increases the heat absorbed by the endothermic segment and released by the exothermic segment. Therefore, the outlet temperature of the produced fluid further increases.

Analyses of the test results of three wells show that the heat-transfer effect of the heat-pipe rod string is not sensitive to the wax mass fraction under the experimental conditions. The heat-transfer effect of a high wax content well (11.08% for Huan-127-26-34) is similar to that of wells with low wax content; the lower the viscosity of the resin and asphalene fractions, however, the greater the heat-pipe transfer efficiency.

Based on the basic heat-pipe theory and the results obtained from tests of the three wells, the following conditions are recommended for wellbore heating with geothermal energy transferred by gravity-heat-pipe sucker rod string:

• Steam stimulation wells with a cycle gas injection rate ≥ 2,000 cu m.

• Crude oil viscosity of less than 10,000 mPa/sec at reservoir conditions.

• Liquid production of at least 15 cu m/day, above 20 cu m/day preferably.

• Reservoir depth of less than 1,300 m and formation fluid temperature at 100-120° C.

Field tests show that it is feasible to improve the temperature field of a wellbore by using a gravity-heat-pipe sucker rod string to absorb and transfer geothermal energy to upper wellbore.

References

1. Yong, Bi, Yonjian, Liu, and Jifu, Liu, "Laboratory experiment on gravity heat pipe sucker rod [J]," Oil and Gas Field Surface Engineering, Vol. 27 (2008), No. 4, pp. 34-35.

2. Yongjian, Liu, Lupeng, Huang, and Wei, Li, "Analysis and calculation the heat transfer characteristics of the gravity heat pipe sucker rod string [J]," Low Temperature Architecture Technology, Vol. 139 (2010), pp. 40-42.

The authors

Shaobin Hu ([email protected]) is associate professor at Northeast Petroleum University, College of Petroleum Engineering, Daqing, China. He works in the laboratory of the Educational Ministry for Improving Oil and Gas Recovery after completing his doctorate in 2011 in oil and gas field development engineering from Northeast Petroleum University. He is a member of the Chinese Petroleum Society.

Lingling Guo ([email protected]) is associate professor at Northeast Petroleum University, College of Computer and Information Technology, Daqing, China. She holds a masters (2003) in applied computer technology from Daqing Petroleum Institute.

Yongjian Liu ([email protected]) is professor at Northeast Petroleum University, Educational Ministry for Improving Oil and Gas Recovery lab, Daqing, China. He is a PhD supervisor and vice-principal of Northeast Petroleum University. He holds a doctorate (1993) in chemical engineering at Zhejiang University and is a member of the Society of Petroleum Engineers.