Novel hull concepts address ultradeep Gulf of Mexico production

Jelena Vidic-Perunovic

Doris Inc.

Houston

Bill Head

Research Partnership to Secure Energy for America

Sugar Land, Tex.

By 2020, according to industry forecasts, deepwater oil production will constitute a third of the world's total oil supply. A strong upswing in deepwater Gulf of Mexico oil exploration is likely (OGJ, May 6, 2013, p. 81), as well as an increase in oil production in Outer Continental Shelf blocks in the gulf's Lower Tertiary. Exploitation of the gulf's Paleogene reservoirs, however, faces several environmental, technical, economic, and geophysical challenges.

In this context, different concepts for ultradeep gulf production and storage have been assessed. Non-ship-shaped, round floating production, storage, and offloading (FPSO) hulls currently appear to be the most appropriate production solution for the ultradeep gulf, capable of complying with physical criteria, safety regulations, and operators' requirements.

This article describes concepts being developed in production technologies through the Research Partnership to Secure Energy for America's (RPSEA) ultradeepwater technologies development program. RPSEA manages a federal research program for the US Department of Energy (DOE), under guidance from the National Energy Technology Laboratory (NETL).

The program was created by the 2005 Energy Policy Act, Section 999, Subtitle J. Section 999 funding by Congress specifically directs research aimed at increasing production of federal reserves in a safe and environmentally sound manner in the ultradeepwater Gulf of Mexico.

Existing technologies

Traditional platforms and towers, applied in shallower waters, rapidly become uneconomical as depth increases. Commonly used concepts for operation in deep water are FPSOs, floating storage and offloading units (FSOs), semisubmersibles, spars, tension-leg platforms (TLPs), and emerging hybrid designs. Functional requirements, depth, subsequent weight of risers, environmental conditions, and the size of topsides usually determine the appropriate concept to be applied for a discovery.

Table 1 outlines existing technology. Concepts are represented by the exemplary production units, covering main subtypes, geographical and operation requirements (storage and production), and the level of technological readiness.

With reservoir discoveries in deepwater Gulf of Mexico, offshore operations move towards water deeper than 3,000 m (more than 9,800 ft) with distances of about 300 km (186 miles) from shore.

These ultradeep and remote locations are distant from existing pipeline infrastructure (Fig. 1). Pipeline extensions into ultradeepwater are complicated due to difficult pipeline design, installation, inspection, maintenance, and repair. In addition, characteristics of marginal field reservoirs are uncertain with limited life span.

Therefore, operators look towards local oil storage, offloaded via shuttle tankers, in order to facilitate exploitation of Lower Tertiary gulf reservoirs. It should be noted that large storage capacity has the advantage of minimizing offloading frequency and affords safe reserve storage in case of shut-in due to hurricanes. The size of shuttle tankers for the gulf is limited by ports' water depths (Galveston's port draft limit, for example: 45 ft at present)1 and tanker availability due to effects of the Jones Act.

Future use of deeper draft vessels will increase after gulf ports have been deepened in response to the Panama Canal expansion (OGJ, Mar. 15, 2010, p. 39). It is reasonable to assume storage capacity of at least 1 million bbl of oil will be sufficient, corresponding to topside production rate of 60,000 bo/d. Thus, oil produced in 16 days can be accommodated allowing a 2-week shuttle cycle.

Further, technology readiness level (TRL) is used as a measure of the level of development of one technology (0-7 scale, according to API 17N or DNV-RP-A203 (July 2011)). Although application of innovative concepts may reduce costs, a higher level of concept maturity is desired by operators because it will shorten the concept's time to market.

Assessment in Table 1 indicates the following hull types with local storage comprise standalone solutions:

• Ship-shaped FPSO.

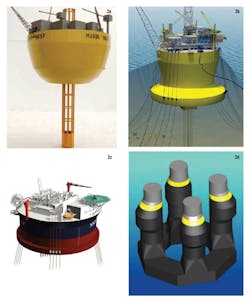

• Non-ship-shaped FPSO (represented by Sevan 1000, SSP Base, SSP 320 Plus; Figs. 2a-c).2-6

• Deep-draft semisubmersible FPSO (represented by Octabuoy, 1 million bbl; Fig. 2d).7

It should be noted that any ultradeepwater oil production concept can be considered in combination with an additional FSO system. The need for a low-cost solution, however, makes a system consisting of more than one unit unlikely to be cost competitive.

Concept assessment

The essential elements for hull applicability in the ultradeep gulf include several aspects of environmental and human safety, operational efficiency, and perceived cost for any floating production and storage solution option.

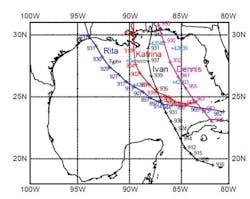

To withstand wave and storm stresses that damage structures, offshore structural design criteria must include responses to the latest hurricane standards associated with (normal) environmental conditions (recommended design waves by API,8 re-evaluated after hurricanes Ivan (2004), Katrina (2005), and Rita (2006); Fig. 3).

The three selected concepts—ship-shaped, non-ship-shaped round hull, and semisubmersible—summarized in Table 2 are discussed here for their main advantages and possible shortcomings.

Stability

The US Coast Guard (USCG) is the lead regulatory authority over floating OCS structures, as outlined in the Memorandum of Agreement between the Minerals Management Service (MMS) and the USCG (MMS/USCG MOA: OCS-04, Subject: Floating Offshore Facilities).9

From reorganization of MMS in 2010 emerged the Bureau of Safety and Environmental Enforcement (BSEE), which became responsible for enforcing safety and environmental regulations related to oil and gas. Classifications recognized by the USCG apply "intact" and "damage stability" standards for different types of offshore installation hulls. For operations in the gulf, stability of a floating unit is reviewed by both the USCG and BSEE.9

Round floaters (Figs. 2a-c), featuring a deeper cross section than a ship-shaped unit, will have a better restoring capability (center of buoyancy, center of gravity) from all wave directions than a traditional ship shape, once the vessel heels from the equilibrium position.

Vessel stability in unloaded condition is provided by use of ballast water. A ballast system is designed so that the capacity and location of ballast tanks ensure the vessel meets stability requirements, maximum trim/heel angle limits for the operation of process facilities, and minimum draft to avoid bottom slamming.

In general, stability of hemispherical bottom shapes is better than that of a flat cylinder. Therefore the original spherically shaped SSP320 should not need active ballasting.2 Permanent ballast has been applied in flat-bottom round vessels with bilge box.

A semisubmersible hull with storage, such as the Octabouy, has been arranged with a complicated ballast system in the octagonal pontoon and columns.7

A well-functioning ballast system and integrated ballast control are vital to this type of hull's operation and safety to withstand changing environmental conditions that cause frequent changes in draught and trim. Such changes in ballast dynamics may happen quickly due to pronounced hull sensitivity to weight during loading or unloading.

Motions

Hull motion is an important consideration for riser selection because it affects riser fatigue life, motion-sensitive process equipment, and everyone aboard. Structures represented by the reduced waterplane area and deep draft (such as round FPSO hulls, spars, semisubmersibles, and TLPs), feature long natural periods in heave.

Natural period of angular motion around horizontal axes is influenced by the metacentric height,10 a measure of the initial static stability of a floating body; yet this parameter must comply with the stability requirements of both physics and regulators.

Motion amplitude, on the other hand, depends on the level of excitation and damping in the system. Rigid body translatory motions and angular displacements in ships are mainly excited by linear waves in the significant energy region. Thus, a ship-shaped FPSO in hurricane conditions may experience excessive motions affecting her operability.

Pitch motion influences a ship-shaped FPSO when risers are located in the fore hull, as is the case with bow turret systems. Baffling is especially important in topsides hydrocarbon separation to compensate for hull motions due to motion-caused dispersion of liquid phases at the interface between oil and water. With round FPSOs, hull motions' frequencies are moved away from the main excitation wave energy content, simplifying the riser location selection on the vessel.

In the absence of direct wave excitation, roll motion can be parametrically excited in the system, due to oscillations in the restoring term, i.e., the metacentric height. The phenomenon is caused by heave and roll oscillations at resonant frequency condition. This is typical for column stabilized units or spars.

The column shape of the semisubmersible hull Octabuoy has been modified to eliminate parametric roll by the introduction of conical columns just below the water line (Fig. 2d). This architecture, however, might disrupt the first-order heave motion. With cylindrical FPSO hulls (for the same heave amplitude), the heave effect becomes less pronounced with increases in hull size (waterplane area).

Structural response

The still-water bending moment ("sagging," "hogging") in a floater occurs solely because of the variation of mass and buoyancy along the hull. Wave-bending moment is further increased by longitudinal wave lengths close to the hull's girder length (or pontoon length on a semisubmersible). For a ship-shaped FPSO hull in the gulf, the important design wave lengths correspond to maximum energy waves (API RP 2A11).

In principle, longitudinal strength in a round floater is improved compared with a long beam because the bending stress is reduced due to hull form (i.e., increased sectional modulus). Ship-shaped FPSOs may suffer notable hull deflections as a result of vertical bending that affects deck and topside interface stool structures, topside structural supports being areas of high stress concentration.12

Hull vertical bending effect on topsides is insignificant on round floaters when the diameter-to-height ratio is close to or less than unity. With semisubmersible hulls, the largest bending moment may be induced on columns, yet the bending stresses are largest on the pontoons and deck.

To reduce dynamic stresses transferred to the Octabuoy deck structure and topsides, a structural brace system is arranged at the top of the columns.7 Column brace joints (designed with small diameter in order not to increase the waterplane area) are susceptible to fatigue damage due to concentration of local stress.

Hull configuration

Both BSEE and the USCG are involved in production and drilling in US waters and in actions related to oil discharge from a floating facility.13 A ship-shaped vessel storing oil is required by the USCG to have a double-hull structure in the tank area (Oil Pollution Act of 1990 resolution).

(The primary purpose of a double-hull structure is to prevent oil leaks in the event of low-energy collision or grounding. Stationary vessels that are not required to escape extreme weather by disconnecting the mooring are not susceptible to grounding while laden.)

A non-ship-shaped hull design also reviewed by both the USCG and BSEE has no specific requirement related to double hull (neither sides, nor bottom).14 Thus, a double-hull structure becomes a criterion under the assumption that a non-ship-shaped production and storage vessel would have to comply with the same regulatory requirements as a ship-shaped FPSO categorized as a vessel.

Water on deck

To mitigate "green water" loading (or deck wetness) effects on the deck, ship-shaped FPSOs are designed with protective breakwaters and bulwarks in front of critical structures on deck. Under fully laden conditions when freeboard is minimum, the deck area may be subjected to heavy green water (more than spray or foam); the most severe would be beam-sea due to focusing of directional wind sea and current.

The associated impact loads may threaten people, hull structure, and topside equipment.15 Owing to its volumetric properties, as compared to a tanker form, a round-shaped hull can be designed economically with significantly greater freeboard for added safety.

Besides green water loads, deck structure on a low air-gap semisubmersible hull is prone to slamming wave impact loads and vortex forces. To reduce the wave loads on deck and topsides, the minimum air-gap between the wave crest and the deck, required by the recommended rules of the classification societies, equals 1.5 m.

Topside arrangement

Arrangement of topsides on the hull is directly related to the unit's floating equilibrium, i.e., trim and stability. To balance a hull on still-water-level, the main consideration hull and topsides weight distribution, riser connection location, and storage and ballast tanks position.

Information on present and future topsides weight is important for maintaining required freeboard and trim. Deck area on a ship-shaped floater or a semisubmersible offers enough space for the safe and functional arrangement of process equipment.

The arrangement of topsides on round floaters might be slightly more challenging in case of reduced deck area, which may lead to an overhang or modules designed in several levels. However, some of the advantages of having slightly shorter distances between the modules are significantly reduced length of piping and cable runs and better crane accessibility.

Hull disconnection

When compared with other deepwater floater solutions, ship-shaped FPSO motion characteristics represent a clear disadvantage that affects riser loads and overall safety and limits the choice of risers in Gulf of Mexico applications. Thus, from the regulatory point of view, it is unlikely that BSEE will approve a permanently moored ship-shaped FPSO in the gulf.

Currently a disconnectable turret mooring-riser system is recommended in order to reduce the effect of environmental loading in severe weather such as hurricanes.16 A self-propelled vessel can sail away, after being disconnected, to avoid extreme weather.

Planning an escape route, though, might be difficult for the crew in wind conditions when, as shown in Fig. 4, most of the gulf is affected because exact path predictions may come too late for a safe haven route.

The main safety hazards recognized with the turret operation are turret seizure and hydrocarbon leakage from flexible risers.17 A risk of cracking is associated with the vessel structure around the internal turret cavity, the upper bearing being the main area of load transfer to the vessel.18 Production downtime is associated with disconnection in hurricane weather.

The need to disconnect in stormy weather and shut down production has been eliminated in case of non-ship-shaped floaters and column-stabilized units due to their favorable motion characteristics.

Lightship weight

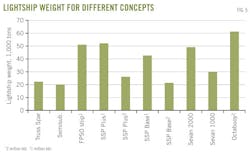

Hull steel weight constitutes a substantial part of total cost of fabrication as well as number of yards capable of building a given hull. Rough estimation in Fig. 5 is based on data provided by SSP Offshore, Sevan Marine, Moss Maritime, published characteristics of truss spar and semisubmersible without storage by Floatec,27 and data published by DNV for a concept vessel Triality.28

As seen in Fig. 5, the hull steel weight of possible concepts with 1 million bbl storage varies between ~20,000 and 30,000 tons. The exception is the 1 million bbl Octabuoy of 61,000 tons, whose hull weight is more than double the comparative round hull types of the same storage capacity, thus affecting the low-cost assumption.

It should be noted that the prediction in Fig. 5 includes uncertainties with regard to both consistency in hull design basis and the technical method of lightship weight estimation. A detailed cost analysis of each selected concept, including mooring, riser and offloading system, as well as topside facilities, must be included in each concept's cost assessment.

BW Pioneer

It has been more than a year since BW Pioneer, the first and only ship-shaped FPSO in the gulf Cascade/Chinook field, received her first oil. During Hurricane Isaac in 2012, FPSO production was shut down and later successfully restarted, yet the mooring system did not have to be disconnected because the storm's wind force was below mooring capability.

With production moving to deeper and more remote fields, stability, weight, motions, structural response, ability to accommodate expanded topside production, safety, and reliability become major concerns. Round hulls maximize storage capacity while meeting production capacity in a floating unit. Non-ship-shaped hulls accord safe operation of a unit encountering gulf conditions.

Moreover, because deepwater operations are very expensive, low capital expenditure and quick return on investment are desired. Future innovation should increase the technological readiness of circular hull solutions for ultradeepwater gulf application.

Acknowledgment

This article represents part of a technology status assessment study under RPSEA project No. 10121-4404-03. Authors acknowledge support by the US Department of Energy, the NETL, and RPSEA Deepwater Program 2010 and assistance of Rick Haun, Doris Inc.

References

1. "Impacts on Texas Ports from the Panama Canal Expansion." Report from the Panama Canal Stakeholder Working Group. Texas A&M Transportation Institute, College Station, Tex., 2012.

2. Haun, R.D. Satellite Separator Platform. United States Patent No. US 6,761,508 B1; 2004.

3. Maksoud, J. "Simplicity, stability, flexibility." Offshore Magazine, October 2007, Vol. 67, No. 10, pp. 78.

4. Vandenworm, J.N., Offshore Buoyant Drilling, Production, Storage and Offloading Structure. United States Patent No. US 2011/0107951 A1; 2011.

5. Cueva, M., Faria, F., Voogt, A., and Vandenworm, N., "Model Tests and Simulations on Circular Shaped FPSO with Dry Tree Solutions," from: www.sspoffshore.com.

6. Sevan Marine. Sylindrisk FPSO for ekstreme miljø. Norsk Offshoredag, Oslo, 2010.

7. Noce, R., and Husem, I., "The Moss Krylov Octabuoy Dry Tree Semisubmersible Drilling and Production Platform," Rio Oil & Gas Expo and Conference. Sept. 13-16, 2010, Rio de Janeiro.

8. American Petroleum Institute. API 2INT-MET Interim Guidance on Hurricane Conditions in the Gulf of Mexico, 2007. Washington, DC.

9. Memorandum of Agreement between the Minerals Management Service, US Department of the Interior and the US Coast Guard, US Department of Homeland Security. MMS/USCG MOA: OCS-04; 2008.

10. Faltinsen, O.M., Sea Loads on Ships and Offshore Structures. Cambridge, UK: Cambridge University Press, 1993.

11. Hussein, M.H., Anderson, J.B., and Camp, W.M., The Art of Foundation Engineering Practice. American Society of Civil Engineers (ASCE). Geotechnical Special Publication No. 198, 2010.

12. Henriksen, L.O., Boyden, D.W., Wang X., and Liu, D. "Structural Design and Analysis of FPSO Topside Module Supports." ABS Technical Paper. SNAME Annual Meeting and Expo. Oct. 15-17, 2008, Houston.

13. "Oil Discharge Planning, Preparedness, and Response." MMS/USCG MOA: OCS-03. Memorandum of Agreement Between Bureau of Safety and Environmental Enforcement-US Department of the Interior and the US Coast Guard-US Department of Homeland Security. Effective date: Feb. 28, 2008.

14. "Floating Offshore Facilities." MMS/USCG MOA: OCS-04. Memorandum of Agreement Between the Minerals Management Service-US Department of the Interior and the US Coast Guard-US Department of Homeland Security. Effective date: Apr. 3, 2012.

15. Ersdal, G., and Kvitrud, A., "Green Water on Norwegian Production Ships," 10th International Offshore and Polar Engineering Conference, May 27-June 2, 2000, Seattle.

16. "BSEE FPSO Regulatory Review Process," Bureau of Safety and Environmental Enforcement BSEE, Emerging FPSO Forum 2012, Sept. 25-27, 2012, Houston.

17. Wall, M., Pugh, H.R., Reay, A., and Krol, J. "Failure modes, reliability and integrity of floating storage unit (FPSO, FSU) turret and swivel systems." Offshore Technology Report 2001/073, AEA Technology Engineering Solutions for the Health and Safety Executive. Norwich, UK: Crown Copyright, 2002.

18. Sii, H.S., Wang, J., Eleye-Datubo, A.G., Yang, J.B., and Liu, J., "Safety assessment of FPSO turret mooring system using approximate reasoning and evidential reasoning." Marine Technology, Vol. 42 (2005), No. 2, pp. 88-102.

19. Dunnahoe, T., "First FPSO in the Gulf of Mexico," Exploration and Production, Apr. 20, 2008, http://www.epmag.com/Production-Field-Development/First-FPSO-the-Gulf-Mexico_3788.

20. http://www.sspoffshore.com.

21. http://www.sevanmarine.com.

22. Tahar, A., and Finn, L., "Inplace Model Test Result Correlation of Multi Column Floater (MCF) – Drilling and Production Unit," OMAE 2010, June 6-11, 2010, Shanghai.

23. Supan, C., "2011 Worldwide Survey of Semi-FPSs and FPUs," Offshore Magazine, January 2011.

24. Mahoney, C.N., and Supan, C., "2012 Worldwide Survey of FPSO Units," Offshore Magazine, August 2012.

25. Mahoney, C.N., and Supan, C., "2012 Deep Water Solutions and Records for Concept Selection," Offshore Magazine, May 2012.

26. "Floating Production Systems," Committee V.2, 17th International Ship and Offshore Structures Congress, Seoul, Vol. 2, August 2009.

27. http://www.floatec.com/images/pr_content/DOT-2006-Presentation.pdf.

The authors

Jelena Vidic-Perunovic ([email protected]) is a senior analyst in naval architecture and risers at Doris Inc., Houston. She has 15 years of experience in applied hydrodynamics and global structural analysis of ships and offshore structures, from both industry and academia. Before joining Doris Inc. Vidic-Perunovic worked at Technical University of Denmark, University of California Berkeley, National Oilwell Varco, and the American Bureau of Shipping. Vidic-Perunovic holds a PhD in maritime engineering from the Technical University of Denmark.

Bill Head ([email protected]) is a project manager for RPSEA's Ultra Deepwater program with more than 38 years of experience in the oil and gas industry. Past positions include general manager and vice-president of technology at independent oil companies; vice-president and chief operating officer at major service company; exploration supervisor and applied researcher at major oil companies, and project manager of applied research for the US Geological Survey's Rocky Mountain Division. Head holds BA, MS, MBA, and JD degrees focusing on intellectual property and is an active member of SEG, AAPG, and SPE.