SPECIAL REPORT: Tests validate new drill pipe buckling model

S. Menand

Mines Paristech

Paris

A. Bjorset

Statoil

Trondheim, Norway

L. Macresy

Drillscan

Montreuil, France

A new drill pipe buckling model provided excellent predictions for each full-scale buckling test performed, not only in terms of deformed buckling shape but also in terms of weight transfer. Existing models, on the other hand, failed to predict observed drill pipe buckling behavior.

This is the first time in the drilling industry that a buckling model was successfully validated in the field, and this model can predict realistically the onset and severity of buckling for any 3D trajectory.

Many articles discuss buckling inside a wellbore, but an increasing number of field observations suggest that existing buckling theories fail to predict buckling phenomenon such as lockup. Indeed, existing buckling theories generally assume that the wellbore is ideal, lacking doglegs.

Recent advancements in drillstring mechanics modeling have demonstrated that doglegs, friction, and rotation affect greatly buckling.

This article compares results of full-scale buckling tests with a new buckling model that takes into account actual wellbore tortuosity.

Buckling

Buckling occurs when the compressive load in a tubular exceeds a critical value, beyond which the tubular is no longer stable and deforms into a sinusoidal or helical shape. The sinusoidal buckling (first mode of buckling) corresponds to a tube that snaps into a sinusoidal shape. This first mode of buckling sometimes is called lateral buckling, snaking or two-dimensional buckling. The helical buckling (second mode of buckling) corresponds to a tube that snaps into a helical shape (spiral shape).

Lubinski initiated the first work dedicated to buckling behavior of pipe in oil wells.1 2 Since then, many researchers have developed theoretical or experimental studies to better understand buckling.

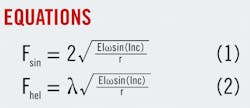

Lubinski first developed his theories for perfectly vertical wellbores without friction.1 Then, Dawson and Paslay proposed buckling behavior of drill pipe in inclined wellbores,3 based on earlier work by Paslay and Bogy.4 This research led to the critical buckling load for sinusoidal mode, Equation 1 in the equation box.

In Equation 1, EI is pipe stiffness, ω is the buoyed linear weight of the pipe, Inc is the wellbore inclination, and r is the radial clearance between the pipe and wellbore. The authors consider the critical force given by Equation 1 as the onset of buckling in an inclined hole, and the drilling industry uses this term widely.

Although a general consensus for the onset of buckling (sinusoidal mode) in a perfect wellbore geometry exists, some controversy regarding the solution for critical helical buckling load remains.5 6 Equation 2 calculates the critical helical buckling in a straight deviated wellbore.

In Equation 2, λ varies from 2.83 to 5.65, depending on the authors and different assumptions taken into account.5 6 In conducting laboratory experiments and numerical analysis in a perfect horizontal well without rotation, Menand et al.7 and Thikonov et al.8 found similar results about the relationship between λ and the deformed shape of drill pipe. A λ close to 2.83 enables prediction of the onset of the first helix, and a λ close to 5.65 enables prediction of full helical drillstring deformation in a perfect wellbore geometry without rotation.

While the industry has many equations for perfect vertical, inclined, horizontal, or curved wellbores, no equations exist for actual geometry in a naturally tortuous wellbore. Based on a new numerical method and an experimental facility, Menand et al.7 have demonstrated the strong effect of tortuosity on the critical buckling load. They have shown for example that a helix could form at a load lower than the critical helical buckling load predicted by all equations found in the literature.

Moreover, most literature equations include simplifying assumptions such as continuous pipe, no rotation, and often ignore the friction between the buckled drill pipe and the constraining wellbore.

It is worth noting that one cannot derive an analytical equation taking into account simultaneously all the effects previously discussed, such as natural tortuosity (doglegs), tool joints, tapered strings, rotation, torque, and friction. One, therefore, has to use numerical modeling for handling this highly complicated problem.

Although this drillstring modeling generally requires finite element analysis, the new model presented in this article uses a semianalytical approach that greatly reduces computational time and remains as accurate and robust as finite-element analysis.

Model summary

The numerical model developed by Mines ParisTech University is for drillstring mechanics from the drilling bit to the rig surface. Previous papers discuss more details such as the main hypotheses and resolution steps for the model.7 9 10

The numerical model now is available in commercial software.

The model can simulate any drilling tool equipment for directional analysis (such as point-the-bit or push-the-bit rotary steerable systems, steerable mud motor, and adjustable gauge stabilizers), for torque-drag and buckling analysis (all tubulars from conventional drillstrings to coiled-tubing), or for sag analysis (wellbore placement uncertainty evaluation). The model takes into account each detail of the element such as drill pipe tool joints.

Because the model meshes the drillstring into small beam elements, one can focus on any critical drillstring component, such as measurement-while-drilling tools or any electronic measurement subs.

The model takes into account any external forces applied on each element of the drillstring, such as hydraulic forces, temperature effect in case of high-pressure and high-temperature wells, and it can handle any new materials such as aluminum, titanium, or composite drill pipe (Young modulus and linear weight variations).

This is the first numerical model that simultaneously can perform torque, drag, and buckling analysis, taking into account the friction analysis that increases the contact force generated by the buckling.

Because of this numerical breakthrough, the software can simulate fully the mechanical behavior of a long drillstring in a 3D well trajectory within a few minutes (instead of hours with finite analysis modeling), making real-time monitoring while drilling possible.

The model requires no assumption as to the points of contact between the drillstring and the borehole, so that it predicts more realistic side forces along the drillstring. This 3D stiff-string model takes into account tubular stiffness, friction, rotation, temperature, hole size, and clearance effects, and can handle the micro and macrotortuosity of actual well paths.

The arrows indicate the contact locations of a buckled drillstring with a horizontal wellbore (Fig. 1).

Fig. 1 shows an example of buckled drill pipe in a perfect horizontal wellbore and highlights the 3D contacts between the wellbore and drillstring.

Full-scale tests</p>

Statoil performed some full-scale tests to evaluate drillstring buckling models that currently exist in the industry.11 The objective was to put different drillstrings in compression (to make them buckle) and then measure the deformed drillstring with a continuous gyroscope.

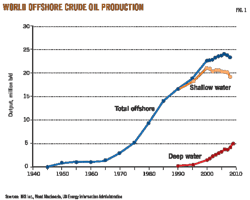

The test well chosen is about 2,020 m deep with a vertical, buildup, and tangent profile (Fig. 2). A downhole weight measurement sub was placed at different parts along the drillstring to control the downhole weight put on the bit. A special weight sub recorded hook load at surface. During the tests, a commercially available continuous wireline gyroscope tool with a 1-m survey spacing determined drill pipe deformation,

This article includes the results from two drillstrings (Table 1). These drillstrings include a bit followed by 5-in. drill pipe, 61⁄2 in. and 8-in. drill collars, and 5-in. drill pipe. The well has 103⁄4-in. casing from the wellhead to 229 m and 95⁄8-in. casing from 229 m to the 2,020-m TD.

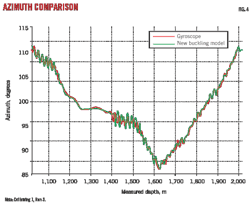

The gyroscope tool enabled measurement of the inclination and azimuth along the drillstring. In this analysis, the interesting information lies in the deviation of the buckled drillstring from the unbuckled reference measurement.

The inclination measurements represent direct deviations from the well path direction in the vertical plane. Azimuth directions are relative to the horizontal plane.

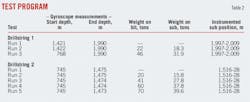

The test applied various weights on bit, from 22 to 70 tons, for buckling the drill pipe in the wellbore. It is worth noting that these full-scale tests were done without pipe rotation and weight was slacked off gradually up to the wanted weight on bit. A previous paper provides more details about the test program and other results.11

The test with Drillstring 2 used a friction factor 0.28 in the simulations based on the recorded 54.5-ton slack off weight and 100-ton pickup weight. The block weight is 9 tons, and the mud density is 1.02 sp gr.

Table 2 lists the weights applied on the bit and parts of gyroscope measurements (start and end depth measurements) for the Drillstring 2 simulation.

Figs. 3 and 4 show the inclination and azimuth as measured by the gyroscope vs. the survey as calculated by the buckling model (survey converted from the pipe deformations) for Run 3 of Drillstring 1 with a 46-ton weight on bit.

The sinusoidal shape of the inclination and azimuth curves indicates that the drillstring buckles either in sinusoidal mode, in helical mode, or neither mode. As already stated, the buckling shape sometimes is linked to the dogleg shape of the wellbore, and it is difficult to determine the mode.

A 400 vertical distance amplification factor helps visualize the deformation of Drillstring 1 in Runs 1, 2, and 3 (Fig. 5).

Fig. 5 shows the 3D view of the deformed Drillstring 1 simulation for Runs 1, 2, and 3.

One notices that without compression (no weight on bit), the drillstring lays on the low side of the borehole, and for the two others compressions, the drillstring strongly buckles.

To better see the buckling phenomenon, Fig. 5 amplifies the deformation on this 3D view by a factor of 400.

One observes in Figs. 3 and 4 that the buckling model reproduced correctly the measurements made by the gyroscope. It is interesting to notice in Fig. 4 that the drillstring does not buckle between 1,150 m and 1,400 m. Indeed, this part corresponds to the position of drill collars that strongly resist buckling

It is important to note that the friction factor has only been fitted for the slack-off (without compression) and pickup test. Without changing this friction factor value for the buckling tests and in taking into account the actual weight on the sub recorded downhole (±3 tons), the buckling model demonstrates that it can reproduce correctly the buckling phenomenon as observed in the field.

Fig. 6 shows the theoretical inclination obtained from the buckling model for three different weights on bit. Note that the sinusoidal variation observed on the curve increases with an increasing weight on bit.

Fig. 7 shows the weight measured at surface vs. the weight on bit during the slack off of Drillstring 2. Note that up to a 30-ton weight on bit, the surface weight follows a normal trend meaning that the slack-off weight is transferred efficiently downhole (normal weight transfer line on the plot).

With a higher weight on bit, the surface weight decreases more rapidly up to the full lock-up, indicating that one cannot apply more weight on bit. Note that the buckling model reproduces properly this tendency.

Equations 1 and 2 from literature are unable to reproduce the buckling phenomenon as observed in these field tests. Indeed, because the wellbore has numerous doglegs, one cannot apply these equations. Moreover, other equations that take into account the local curvature effects give nonconsistent results.12 OGJ

References

1. Lubinski, A., "A study On the Buckling Of Rotary Strings," API Drilling Production Practice, 1950, pp. 178-214.

2. Lubinski, A., Althouse, W.S., and Logan, J.L., "Helical Buckling of Tubing Sealed in Packers," Paper No. SPE 178, 36th Annual Fall Meeting of SPE, Dallas, Oct. 8-11, 1961.

3. Dawson, R., and Paslay, P.R., "Drillpipe Buckling in Inclined Holes," JPT, October 1984, pp. 1734-38.

4. Paslay, P.R., and Bogy, D.B., "The Stability of a Circular Rod Laterally Constrained to Be in Contact With an Inclined Circular Cylinder," Journal of Applied Mechanics, December 1964, pp. 605-10.

5. Cunha, J.C., "Buckling of Tubulars Inside Wellbores: A Review on Recent Theoretical and Experimental Works," Paper No. SPE 80944, SPE Production and Operations Symposium, Oklahoma City, Mar. 22-25, 2003.

6. Aasen, J.A., and Aadnoy, S., "Buckling Models Revisited," Paper No. SPE/IADC 77245, SPE/IADC Asia Pacific Drilling Technology and Exhibition, Jakarta, Sept. 9-11 2002.

7. Menand, S., Sellami, H., Tijani, M., and Akowanou, J., "Buckling of Tubulars in Actual Field Conditions," Paper No. SPE 102850, SPE Annual Technical Conference and Exhibition, San Antonio, Sept. 24-27, 2006.

8. Tikhonov, V.S., Safronov, A.I., and Gelfa, M.Y., "Method of Dynamic Analysis of Rod-In-Hole Buckling," Paper No. ESDA2006-95059, 8th Biennal ASME Conference on Engineering Systems Design and Analysis, Torino, Italy, July 4-7, 2006.

9. Menand, S., Sellami, H., Akowanou, J., Isambourg, P., Simon, C., Macresy, L., and Dupuis, D., "How Does The Drillstring Rotation Affect The Critical Buckling Load?," Paper No. SPE/IADC 112571, SPE/IADC Drilling Conference and Exhibition, Orlando, Mar. 4-6, 2008.

10. Menand, S., Sellami, H., Bouguecha, A., Isambourg, P., and Simon, C., "Axial Force Transfer of Buckled Drill Pipe in Deviated Wells," Paper No. SPE/IADC 119861, SPE/IADC Drilling Conference and Exhibition, Amsterdam, Mar. 17-19, 2009.

11. Weltzin, T., Aas, B., Andreassen, E., and Lindland, M., "Measuring Drill Pipe Buckling Using Continuous Gyro Challenges Existing Theories," Paper No. SPE/IADC 115930, SPE/IADC Asia Pacific Drilling Technology Conference and Exhibition, Jakarta, Aug. 25-27, 2008.

12. Kuru, E., Martinez, A., Miska, S., and Qiu, W., "The Buckling Behavior of Pipes and Its Influence on the Axial Force Transfer in Directional Wells," Paper No. SPE/IADC 52840, SPE/IADC Drilling Conference and Exhibition, Amsterdam, Mar. 9-11, 1999.

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com