TRINIDAD EOR—2 (Conclusion): Carbon dioxide injection holds promise offshore

Raffie Hosein

Wayne Bertrand

Richard Dawe

University of West Indies

St. Augustine, Trinidad

With the experiences gained during the last 30 years, Trinidad can sequester carbon dioxide safely in its west coast offshore heavy oil reservoirs and at the same time recover another 6% from its offshore heavy oil reservoirs after the primary production phase.

This conclusion is based partly on the Petroleum Oil Co. of Trinidad and Tobago (Petrotrin) pilot scale carbon dioxide injection projects onshore. One driver is cheap and available supply of CO2 in Trinidad.

This concluding part of a two-part series on Trinidad EOR will discuss this EOR potential. The first part (OGJ, Sept. 5, 2011, p. 62) covered the potential for recovering Trinidad's onshore and west coast heavy resources with thermal processes.

Trinidad's resources

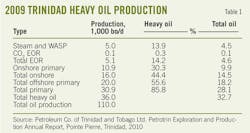

Trinidad, as in Venezuela, has heavy 10-22° gravity oil resources onshore and off the west coast. In 2010, the country produced 36,000 b/d of heavy oil, which equals about 30% of the country's total production (Table 1).

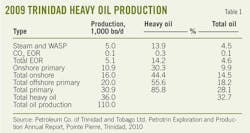

Off the west coast (Fig. 1), heavy oil production is about 20,000 b/d mainly by primary methods and some foamy oil.1

Despite this production, many heavy oil areas off the west coast (more than 2 billion bbl) are yet to be exploited (Fig. 1). Potential means for producing this resource include cold heavy oil production with sand (CHOPS), foamy oil production, and enhanced oil recovery such as carbon dioxide injection.2

These reservoirs lie at depths of 4,000-6,500 ft in the Forest, Cruse, and Manzanilla formations. The oil has an 11-20° gravity and 10-3,500 cp viscosity at reservoir conditions.

Trinidad also produces about 4 bcfd of gas from fields off the east and north coast. About 1.5 bcfd of this gas is processed at Point Lisas (Central Trinidad) and used for power generation, and the manufacture of methanol and ammonia. The remaining 2.5 bcf is processed near the southwest coast at Point Fortin and converted to LNG, of which about 65% is exported to the US.

The Point Lisas and Point Fortin plants generate about 125 MMscfd of CO2. A small part of this CO2 has been injected into heavy oil reservoirs to enhance recovery.

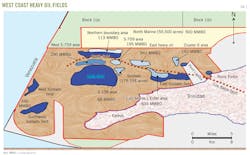

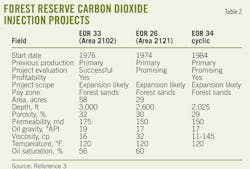

For three heavy oil CO2 projects in Trinidad, one was ranked as successful and two as promising (Table 2).3 Projects EOR 33 and EOR 26 are immiscible whereas EOR 34 is a cyclic huff and puff.

Mohammed-Singh et al. provides screening guidelines for CO2 huff-and-puff injection.4 They show this oil recovery method could be successful even without communication between wells. Based on performance evaluation, they provide guidelines for efficient production practices for CO2 immiscible and CO2 huff and puff.4

All three CO2 injection pilots in Trinidad are onshore in the Forest Reserve area (Fig. 2). The projects used a small amount of the CO2 generated at the plants at Point Lisas.

Carbon dioxide injection

In Trinidad, the first CO2-EOR project started in 1973 in the Forest Reserve as a replacement for natural gas injection.

The worldwide EOR surveys published in OGJ 1992-2010 indicate that by 1976 the Forest Reserve had two immiscible heavy oil CO2 projects.3 Both onshore projects used existing wells and equipment and were thus described as a poor boy implementation.5

The main driver was an abundant but unreliable supply of CO2 at an attractive $0.10/Mcf price. The CO2 injected in both projects was immiscible, and the projects were designed to be gravity stable with water injection down dip and CO2 injection up dip or near the crest of the structure.5 The reservoirs have a 10-30° dip.

In addition to immiscible flooding, since 1984, the Forest Reserve fields have had 16 CO2 huff-and-puff projects with a 3-5 day soak period and more than 6-month production cycle.5

The selected wells were initially medium to heavy oil producers that were inactive or produced less than 5 bo/d from the Forest Cruse and Morne L'Enfer formations. CO2 for these projects came from the nearby immiscible floods that obtained CO2 from a 25-mile pipeline to an ammonia plant.

Mohammed-Singe and Singhal4 provide details on well operation, production, performance on successive injection cycles, and factors favorable to CO2 huff-and-puff operations.

Petrotrin has operated all these CO2 projects.

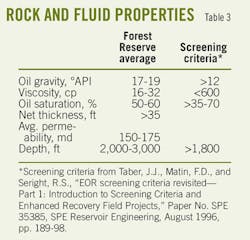

Tables 2 includes the depths and reservoir rock and oil properties for the immiscible projects. Table 3 compares these data with screening criteria.6

These reservoirs have 17-19° oil gravities, 16-32 cp viscosities at reservoirs temperature and 50-60% oil saturation (after primary and secondary production) of the original oil in place (Table 2).3

The reservoirs lie at a 2,000-3,000 ft depth with a 73-290 ft thickness and 150-175 md permeability. These properties and the relatively shallow depths make these reservoirs suitable candidates for immiscible oil recovery.

The wells under huff-and-puff operations have 1,150-4,200 ft reservoir depth with a 35-395 ft reservoir thickness, and 150-335 md permeablity.4 The 14-25° oil gravity increases with depth, and the oil has a 13-3,000 cp viscosity at reservoir temperature.4

A critical parameter for CO2 huff-and-puff operations is the cost of implementation and CO2.

Performance evaluation

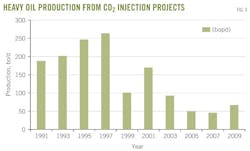

Trinidad's average heavy oil production by CO2 injection peaked at 250 b/d in 1997 (Fig. 3). An unreliable supply of CO2 caused the variation in production.

Nevertheless, an evaluation determined Project EOR 33 was successful, recovering 8% of the original oil in place and EOR 26 was promising, recovering 6% of the original oil in place.4

The huff-and-puff operation, EOR 34, although evaluated as promising, should be considered successful since it showed a profit (Table 2).

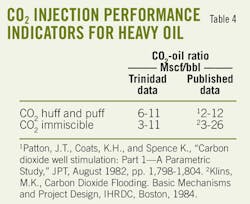

Mohammed-Singh and Singhal indicated that an efficient production practice for heavy oil recovery is a 3-11 Mcf/bbl CO2 injection rate.5 For the CO2 huff-and-puff operations, the range is 6-11 Mcf/bbl for heavy oil during a maximum of five cycles, an average slug size of 1 MMcf/ft of net sand, a soak period of 3-5 days, and production cycles of more than 6 months.5

Table 4 summarizes the injection-production ratio for heavy oil recovery projects in Trinidad.

Steamflood wind-down

CO2 injection is a potential process when oil production from Trinidad's mature steamflood projects onshore begins to dwindle to where it no longer is economic to inject steam or continue with a water-alternating-steam process (WASP).

CO2 injection has been evaluated for wind-down operations in steam-assisted gravity drainage projects in Alberta.6

The injection of CO2 helps maintain reservoir pressure when steam injection stops. In addition the CO2 diffuses much more readily in the heated oil and further reduces viscosity.

Pressure maintenance and viscosity reduction can provide additional recovery during the steamflood wind down.7

The future

Many heavy oil areas off Trinidad's west coast remain unexploited. These reservoirs are at 4,000-6,500 ft depths in the Manzanilla, Forest, and Cruse formations.

The reservoirs mostly contain 11-20° gravity oil (with some oil in the 30° gravity range) with 10-3,500 cp viscosity.

Besides CO2 injection, CHOPS using horizontal wells and foamy oil production, which is popular in Venezuela and the North Sea,2 8 also could be tested in the heavy oil reservoirs off Trinidad.

Platform size limits the number of wells during primary recovery, but drilling a few horizontal wells is a way of increasing well production rate without causing excessive drawdown and as much sand production as from vertical wells.

A CO2 injection and sequestration program could follow primary production.8

Given that CO2 is cheap and readily available, Trinidad has the potential to embark on an aggressive CO2 injection and sequestration program to increase its heavy oil production offshore.

Currently a 3D seismic project across the major heavy oil fields will help determine reservoir continuity and fault block identification and reservoir characterization and simulation studies will aid in suitable well placement for injection and producing wells.

Another possibility is to drill horizontal wells for CO2 huff and puff and CO2-assisted gravity drainage (CO2-AGD). With dipping reservoirs, the injection of CO2 up dip (production well down dip) or into the gas cap will maintain reservoir pressure and increase recovery by gas-cap drive. In addition the diffusion of CO2 into heavy oil will cause the oil to swell, reduce viscosity, and increase oil mobility.

Acknowledgments

The authors thank Lorna Mohammed-Singh from Petrotrin and Craig Boodoo from the Ministry of Energy and Energy Affairs for their assistance in providing supporting data. Thanks also to Clyde Abder from the University of The West Indies for his technical input on the operational practices of cyclic and continuous CO2 injection in Trinidad.

References

1. Babwah, J.A., Dawe, R.A., and Mellows, W., "Foamy Oil Production in Trinidad," West Indian Journal of Engineering, Vol. 28, No. 2, 2005, pp. 1-12.

2. Dusseault, M.B., 2006. "CHOPS—Cold Heavy Oil Production with Sand," Chapter 5, Petroleum Engineers Handbook, L.W. Lake editor, SPE, Richardson, Tex., 2006.

3. EOR-Heavy oil surveys, OGJ, Apr. 20, 1992, p. 19; Sept. 26, 1994, p. 51; Apr. 15, 1996, p. 39; Apr. 20, 1998, p. 49; Mar. 20, 2000, p. 39; Apr. 15, 2002, p. 43; Apr. 12, 2004, p. 45; Apr. 17, 2006, p. 37; Apr. 14, 2008, p. 45; Apr. 19, 2010, p. 36.

4. Mohammed-Singh, L., Singhal, A.K., and Sim, S., "Screening Criteria for Carbon Dioxide Huff n Puff Operations," Paper No. SPE 100044, SPE/DOE Symposium on Improved Oil Recovery, Tulsa, Apr. 22–26, 2006.

5. Mohammed-Singh, L., and Singhal, A.K., "Lessons from Trinidad's CO2 Immiscible Pilot Projects, Paper No. SPE 89364, SPE Reservoir Evaluation and Engineering, Oct. 2004, pp. 397-403.

6. Law, D.H.S., "Disposal of Carbon Dioxide, a Greenhouse Gas, for Pressure Maintenance in a Steam-Based Thermal Process for Recovery of Heavy Oil and Bitumen," Paper No SPE 86958, SPE International Thermal Operations and Heavy Oil Symposium, Bakersfield, Calif., Mar. 16-18, 2004.

7. Hite, R.K., Avasthi, S.M., and Bondor, P.L., "Planning EOR Future," Paper No. SPE 92006, SPE International Petroleum Conference, Puebla, Mexico, Nov. 7-9, 2004.

8. Dusseault, M.B., and El-Sayed, S., "CHOP—Cold Heavy Oil Production," Paper No. 086, 10th European Symposium on Improved Oil Recovery, Brighton, UK, Aug. 18, 1999.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com