Mazen Al-Saleh

Peter Sanders

Tawfiq Al-Ibrahim

Saudi Aramco

Dhahran

Susanne Juhler

Ketil Sorensen

Thomas Lundgaard

Danish Technological Institute

Aarhus, Denmark

| Based on presentation to NACE Corrosion 2011 Conference, Houston, Mar. 13-17, 2011. |

Genetic characterization of microbes present in crude oil samples makes possible the design of optimized assays for surveillance and troubleshooting of microbially influenced corrosion (MIC).

Chemical and microbiological analyses of water condensates during the first phase of applying molecular microbiology methods (MMM) to risk assessment of microbially influenced corrosion of Saudi Aramco's crude pipelines showed microorganisms, many with the potential to cause MIC, present in numbers comparable to other systems with documented incidences of MIC.

This article discusses research conducted in Saudi Aramco Research and Development Center to develop MIC assessment protocols introducing MMM to confirm MIC as the cause of corrosion in a specific case and procedures to conduct reliable field monitoring of MIC.

Initial stages of the project collected several water and solid samples from different sites along a single crude oil pipeline. Analysis sought to:

• Determine how many and what types of microorganisms are present in the samples through MMM.

• Determine the chemical nature of the water in the system through geochemical analysis.

• Investigate the presence of bacteria in solid and filter samples through environmental scanning electron microscopy and energy dispersive x-ray spectroscopy (ESEM-EDS).

Results of these analyses provided necessary background information for further implementation of MMM for MIC risk assessment in the Aramco crude oil pipeline system.

Background

Corrosion resulting from the attachment and activities of microorganisms on metal surfaces is microbiologically influenced corrosion (MIC). It occurs in diverse environments and is not limited to aqueous submerged conditions, but also takes place in humid atmospheres. It is an electrochemical process in which the participation of microorganisms is able to initiate, facilitate, or accelerate the corrosion reaction without changing its electrochemical nature.1

MIC stems from interactions that are often synergistic among the metal surface, abiotic corrosion products, and microbial cells and their metabolites. The latter includes organic and inorganic acids and volatile compounds, such as ammonia and hydrogen sulfide. Microbiologically mediated reactions do not result in a unique type of corrosion, but they can induce localized corrosion, change the rate of corrosion, and also inhibit corrosion.2

Most MIC studies have focused on bacterial involvement. Under aerobic conditions, however, other single-celled organisms, such as fungi, yeast, and diatoms, can influence corrosion.3 The predominant types of bacteria associated with MIC are sulfate-reducing bacteria (SRB), sulfur-oxidizing bacteria, iron-oxidizing-reducing bacteria, manganese-oxidizing bacteria, and bacteria secreting organic acids and slime.4 These organisms coexist within a biofilm matrix on metal surfaces, functioning as a consortium, in a complex and coordinated manner.

The various mechanisms of biocorrosion reflect the variety of physiological activities carried out by these different types of microorganisms when they coexist in biofilms. Decades of study on MIC have so far failed to determine how many species of microorganisms contribute to corrosion, and researchers continue to report on the formation of biofilms by an ever-widening range of microbial species.

The high diversity of microorganisms and mechanisms potentially involved in MIC has made it hard to predict and assess the process before substantial damage has already occurred. Recent technological advances in the field of molecular microbiology have now made it possible to detect and enumerate specific MIC-promoting microorganisms with a much better precision than previously. Given proper procedures for sampling and analyzing field material, it has now become possible to perform a reliable screening of industrial systems for potentially harmful microorganisms and to use this information in a MIC risk analysis.

Saudi Aramco in collaboration with the Danish Technological Institute launched a joint research project in early 2010 to introduce molecular microbiology methods (MMM) as a tool for failure analysis and MIC risk assessment in Aramco's crude oil pipeline system. This article presents the initial findings of the project and outlines future steps.

Researchers collected sets of water and solid samples (after scraping) from across the targeted crude oil pipeline system and analyzed and evaluated them with respect to microbiological and chemical composition. A general microbiological population study using several molecular microbiology methods determined how many and what types of microorganisms were present in the system.

This microbiological characterization will provide the basis for development of customized laboratory kits and protocols for the detection and enumeration of MIC-related microorganisms in the Aramco crude oil pipeline system. Knowledge of the chemical composition of the water phase in the pipeline will be valuable for developing procedures to extract microorganisms and DNA from crude oil.

Experimental procedure

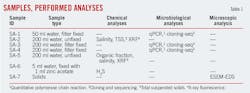

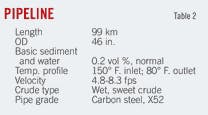

Water samples collected from a vertical outlet in the crude oil pipeline system determined the basic water chemistry and microbiology in the system (Table 1). Table 2 provides a general description of the studied pipeline.

Filtering of samples SA-1, SA-3 and SA-4 occurred immediately after sampling, and the filters were stored in a fixation buffer for later microbiological analysis. Samples SA-2, SA-5 and SA-6 served for chemical analysis of the water. An evacuated container containing a 20% zinc-acetate solution to preserve any reduced sulfur in the water collected sample SA-6.

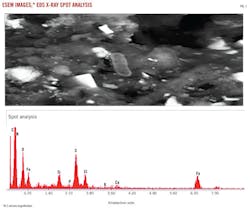

Researchers gathered and immediately preserved a solid (debris) sample (SA-7) from the scraper trap receiver area during scraping operations. Subjecting this sample to laboratory testing with ESEM/EDS investigated the presence of bacteria and the chemical composition, including corrosion products, of the solid samples.

Chemical analysis

Characterization of the water samples from the identified crude oil pipelines took place according to its organic matter content, salinity, H2S concentration, and inorganic elemental composition. Filtrating part of each sample determined the amount of total suspended solids (TSS). Drying the second part determined its organic content by loss of ignition (at 550° C.). Drying and homogenization preceded analysis of the inorganic elemental solids with wavelength dispersive x-ray fluorescence (WDXRF) spectroscopy. Spectrometry determined the concentration of dissolved hydrogen sulfide in the water.

Population studies

Analyzing the water samples for total microbiological cell numbers allowed characterization with respect to microbiological community composition. Quantitative polymerase chain reaction (qPCR) analysis of the 16S rRNA gene content in the sample determined total microbiological cell numbers. This method amplifies genetic material extracted from samples as a basis for qualifying microorganisms.

Results given as number of genes (genetic units or GU) per ml sample correspond to the number of microorganisms within a factor of 2-3. (Some groups of microorganisms have more than one 16S rRNA gene copy, and therefore the number of genes is usually a bit higher than the number of microorganisms.) The total number of bacteria and archaea were quantified separately, with the sum providing information on total prokaryotic numbers.

Cloning, sequencing, and phylogenetic analysis of specific target genes determined the microbiological community composition. Characterizing the bacteria and archaea present in the water samples required amplifying the 16S rRNA genes with bacteria and archaea-specific primers, respectively. Studying the sulfate-reducers required amplifying and characterizing genes for the A and B subunits of dissimilatory sulfite reductase (dsrAB).

ESEM-EDS

A high resolution ESEM integrated with EDS analyzed the solid samples. The ESEM operated at 15 kV, 0.23-0.7 torr water vapor pressure and working distance of about 8 mm. ESEM acquired backscattered electron images together with EDS x-ray spectra from different parts of the samples. A double-sided carbon tape mounted the samples on the ESEM sample holder.

Results

Tables 3-5 list results of the chemical measurements. The salinity in the water measured 14.5%, and the main salts were CaCl2 and MgCl2. A small amount of sulfide was detected (5.4 mg/l.). Total suspended solids (TSS) amounted to 120 mg/l. and consisted mainly of BaSO4, SrSO4, organic material, and Fe-containing corrosion products.

Quantification

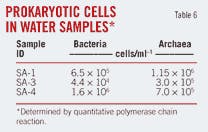

Triplicate samples determined the total number of microorganisms in water from the crude oil pipeline bypass, indicating both archaeal and bacterial numbers in the range 105-106 cells/ml–1 (Table 6). The study could not determine how the number of microorganisms in these water samples related to the number of microorganisms in the crude flowing in the pipelines. This determination will happen once the procedures for extracting cell material and DNA from crude samples have been developed.

Table 6 shows the size of the total microbial populations and thereby gives an idea about the overall microbiological status of the system. Knowing the number of specific MIC-causing microorganisms rather than total cell numbers would allow a much better MIC risk analysis.

qPCR may quantify MIC-causing microorganisms, such as sulfate reducers and methane producers, in a manner similar to the total bacterial and archaeal populations in Table 6. But doing this reliably requires determining which microorganisms are present in the system and optimizing the qPCR assay on that basis.5 Tables 7-9 further characterize the microorganisms in the system.

Identification

Testing detected nine different types of bacteria (Table 7). Some of these clusters were similar to cultured and well-characterized microorganisms, including several types of thermo- and mesophilic bacteria that have been shown to live from SO42–, NO3– or Fe3+ reduction or by fermentation of organic material. Other clusters (Unknown Bacterial Cluster I, II, and III in Table 7) represented completely unknown groups of bacteria never before cultured or characterized.

Some of these clusters show similarity to DNA sequences found in thermophilic environments, but their function is completely unknown. These unknown clusters made up a large fraction of the clone library (75 out of 110 analyzed sequences, or 68%). It remains unknown whether these bacteria are growing and active in the pipeline system or represent dormant organisms originating from the oil reservoir, but their function may be highly relevant and potentially related to MIC in the system.

Testing detected a total of seven different types of archaea (Table 8). Three of these clusters (Unknown Archaeal Cluster I, II and III) showed no similarity to previously characterized organisms. These three exotic archaeal groups comprised 51 of 166 sequences, or 31%. As with the unknown bacterial clusters, the function of the unknown archaea remains enigmatic.

A large fraction of the remaining sequences in the archaeal clone library was related to methane-producing microorganisms (109 of 166 sequences, or 66%). One of the methanogen clusters detected was related to the genus Methanothermococcus, which has often been found in scale material close to corrosion points in production pipeline systems.1 This organism has also shown a propensity to accelerate corrosion of metal test coupons in laboratory studies.6 Several lines of evidence therefore show Methanothermococcus' involvement in MIC.

The other two clusters of methanogens detected in the water sample carry out the same processes as Methanothermococcus, but their involvement in corrosive processes is less well documented. Biocides employed by the oil and gas industry have in general not been tested for their efficacy in mitigating methanogens or other archaea. This article's findings suggest future biocide test programs should include methanogens.

Testing sequenced the dsrAB genes in the samples to characterize the sulfate-reducing microorganisms in more detail. This analysis showed four different types of SRB as present (Table 9). The detected SRB are all known from other systems, and together they use a diverse selection of organic substrates as well as hydrogen for the production of sulfide. No sulfate-reducing archaea (SRA) were found. The presence of SRB in the system correlated well with the detection of sulfide in the water samples, and confirmed that SRB are growing and active in the system.

ESEM-EDS investigation

ESEM-EDS results identified the main elements in the samples as carbon, oxygen, iron, and sulfur with small amounts of silicon, calcium, chlorine, potassium, and sodium (Fig. 1). Results also clearly showed microorganisms present, suggesting the presence of bacteria as contributing, as also shown by iron's presence.

MMM-based enumeration of MIC-causing microorganisms can provide a sensitive tool for early warning of MIC events, for general system surveillance, and for failure analysis in Aramco's crude oil pipeline system, but still requires:

• Development of protocols for handling of crude samples. Analysis of crude oil presents unique problems as compared to analysis of water. Extraction of microbial cells from the oil matrix is not, for example, trivial and various oil components may be detrimental to downstream analysis if samples are not properly purified.

• Optimizing analytical protocols. No universal assay exists for specific enumeration of troublesome microorganisms, such as sulfate-reducers or methane-producers, from oil systems. It is, however, possible, based on the information presented in this article, to design customized qPCR assays for both these groups in Saudi Aramco's crude pipeline systems.

• Understanding the link between cell numbers and MIC risk. The final critical step in MMM-based MIC risk assessment is translation of cell numbers into a reliable risk factor. Based on experience from produced water from other systems, total prokaryotes detected in sample SA-1 and SA-4 are relatively high, while the number in sample SA-3 is not. The cell numbers from oil systems in other regions, therefore, may not be comparable to those in the Aramco's system. More detailed MIC risk analysis will become possible as a more comprehensive dataset is collected from Aramco's crude oil pipeline system.

References

1. Videla, H.A., "Manual of Biocorrosion," Boca Raton, Fla.: CRC Lewis Publishers, 1996.

2. Videla, H.A., "Corrosion Inhibition in the Presence of Microbial Corrosion," NACE Corrosion 1996, Denver, Mar. 25-28, 1996.

3. Prasad, R., "Assessment and Control of MIC in the Oil Industry in the 20th Century," NACE Corrosion 2000, Orlando, Mar. 26-31, 2000.

4. Beech, I.B., and Gaylarde, C.C., "Recent Advances in the Study of Biocorrosion—An Overview," Review of Microbiology, Vol. 30, No. 3, pp. 177-190, March 1999.

5. Skovhus, T.L., Sorensen, K.B., Larsen, J., Rasmussen, K., and Jensen, M., "Rapid Determination of MIC in Oil Production Facilities with a DNA-based Diagnostic Kit," SPE International Conference on Oilfield Corrosion, Aberdeen, May 24-25, 2010.

6. Daniels, L., Belay, N., Rajagopal, B.S., and Weimer, P.J., "Bacterial Methanogenesis and Growth from CO2 with Elemental Iron as the Sole Source of Electrons," Science, Vol. 237, pp. 509-511, July 3, 1987.

7. Larsen, J., Sorensen, K., Hojris, B., and Skovhus, T.L., "Significance of Troublesome Sulfate-reducing Prokaryotes (SRP) in Oil Field Systems," NACE Corrosion 2009, Atlanta, Mar. 22-26, 2009.

The authors

Mazen Al-Saleh ([email protected]) is a laboratory scientist at Research & Development Center, Saudi Aramco, Dhahran. He has also served as a chemist at the National Methanol Co. (IBN SINA). He holds a BS (1996) in chemistry from Toledo University, Toledo, Ohio. He is a member of the American Chemical Society.

Peter Sanders ([email protected]) is a research science consultant at R&D Center, Saudi Aramco, Dhahran. He has previously worked at Aberdeen University, Micran Ltd., and Oil Plus Ltd. in senior technical capacities. He holds a PhD (1978) in microbiology from Exeter University, UK. He is a member of the Society for General Microbiology.

Tawfiq Al-Ibrahim ([email protected]) is a science specialist at R&D Center, Saudi Aramco. He holds a BS (1990) in chemistry from the University of Alabama. He is a member of the American Chemical Society.

Susanne Juhler ([email protected]) is a consultant microbiologist at Danish Technological Institute, Aarhus. She holds a PhD (2009) from Aarhus University, Aarhus, Denmark.

Ketil Sorensen ([email protected]) is a microbiologist at Danish Technological Institute, Aarhus. He also has 5 years of postdoctoral experience from in the US and Europe. He holds a PhD (2002) from Aarhus University and is a member of the American Society of Microbiology.

Thomas Lundgaard ([email protected]) is center manager at Danish Technological Institute, Aarhus. He holds an MS (2005) in environmental engineering from Aalborg University. He is a member of the Society of Petroleum Engineers.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com