dGB Earth Sciences, Enschede, Netherlands, and ARK CLS, Bedford, UK, have launched a direct data link between dGB's OpendTect software and Houston-based Schlumberger Ltd.'s Petrel seismic to simulation software.

The OpendTect connector plug-In for Petrel software, developed by ARK CLS using Schlumberger's Ocean software development framework, will provide the Petrel user community with access to OpendTect's commercial plug-ins relating to areas such as attribute and processing analysis, sequence stratigraphy, fluid migration, rock property predictions, and velocity modeling.

Three-dimension horizons, including time/depth horizons, and high quality attribute volumes generated by OpendTect, can all be incorporated into Petrel software, enabling users to build reservoir models, maximize their geological data, and bridge the gap between seismic quantitative interpretation and more production-focused reservoir models.

In all cases, interpreters will be able to seamlessly export and import seismic data between the Petrel work-flow manager and OpendTect with no need to move separate SEG-Y files back and forth between applications as was done previously.

Source: dGB Earth Sciences BV, Nijverheidstraat 11-2, 7511 JM, Enschede, Netherlands.

Artificial lift product updatedThe latest version of APOLLO artificial lift solution is designed for installations in 51⁄2 in. production tubing.

The APOLLO 190/55 includes all the features of the previous version (the 190/35) but will offer additional gas injection points—a total of nine—for the wider production tubing that it is designed for. A version of APOLLO, which fits 27⁄8 in. tubing, utilized when reservoir conditions deteriorate, is also being developed, which will help reduce the number of injection points to four.

The APOLLO portfolio of products uses digital valve technology based on the firm's patented, ultralow energy binary actuation technology. APOLLO enables operators to vary injection rates in real time without production interruption and well intervention, and generate pressure and temperature information throughout the gas injection process.

Source: Camcon Oil, Button End Industrial Estate, Harston, Cambridge CB22 7GX, UK.

Engine compliance guideA new guide is available to help the industry comply with the impending US Environmental Protection Agency's National Emission Standards for Hazardous Air Pollutants for Reciprocating Internal Combustion Engines (RICE NESHAP).

The guide offers answers to: Do you need to comply? What steps are required to bring a reciprocating engine into compliance? How do I minimize engine back pressure? And what solutions are available? These questions are covered in "Compliance Guide to EPA's 40CFR Part 63" catalog. The guide is designed to help make the ruling easy to understand, and it provides products designed exclusively to bring an engine into RICE NESHAP compliance.

Source: Universal LLC, 1925 Highway 51 and 138 West, Box 411, Stoughton, WI 53589.

Reservoir modeling softwareThe next generation of JewelSuite reservoir modeling software—JewelSuite 2011—now available to the industry uses patented 3D gridding technology to build accurate reservoir models for fields with complex geology. The platform also provides connectivity between its generated models and reservoir simulators.

JewelSuite 2011 includes technologies that extend the scope of the software and the associated subsurface 3D modeling work flows:

• A new approach to earth modeling collaboration.

• Linked software platforms to enhance work flows.

• More powerful processing via multithreading and multicore functionality.

• Enhanced work flows for modeling unconventional reservoirs.

New collaboration functionality allows team members to share information with or without a traditional hub-and-spoke database approach.

Multithreading and multicore functionality, along with work-flow automation, allow users to make faster decisions with the advantage of modern multiple core processor architecture(s), which lets them process scenarios on two cores while simultaneously evaluating or building new, alternative scenarios on additional cores.

Source: Baker Hughes Inc., 2929 Allen Parkway, Suite 2100, Houston, TX 77019.

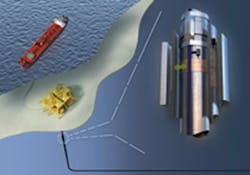

Tool measures pressure behind well casingHere's the Roxar downhole wireless PT sensor system—annulus B. It measures on line and in real time previously inaccessible pressure and temperature information behind the casing in underwater production wells, providing operators with a new tool for well integrity monitoring.

With on line pressure monitoring, the unit can provide positive confirmation of the pressure barrier's integrity. The firm says the tool will also negate the sometimes excessive and expensive overdimensioning of casings that can take place to compensate for worst case scenarios and will also potentially provide operators with cost savings previously incurred in shutting in wells, due to their lack of ability to verify barrier integrity.

Source: Emerson Process Management, 8000 W. Florissant Ave., St. Louis, MO 63136.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com