System-wide ECDA application advances integrity management

Ashish Khera

Allied Engineers

New Delhi

James E. Marr

TransCanada Pipelines Ltd.

Calgary

Saleh Al-Sulaiman

Abdul Wahab Al-Mithin

Shabbir T. Safri

Kuwait Oil Co.

Ahmadi, Kuwait

Based on presentation to ASME's International Pipeline Conference, Calgary, Sept. 27-Oct. 1, 2010.

Applying an initial external corrosion direct-assessment program to Kuwait Oil Co.'s pipeline network advanced integrity management of the facility despite initial setbacks. Based on the initial ECDA program, KOC determined that a single entity should have accountability and responsibility for all the four stages of ECDA in future programs, thereby improving data acquisition and related quality assurance-quality control, data integration, and postassessment processing to tie in all the stages of ECDA.

The initial ECDA program also established the basis for KOC to conduct future programs on a line-by-line basis, rather than in stages across the complete system. KOC determined pipelines should be further subdivided into unique ECDA regions based on common physical characteristics of the pipe as well as operational and risk characteristics. Such subdivisions would allow implementation of customized or nontraditional indirect inspection (IDI) techniques capable of addressing congested rights-of-way, oil lakes, and other difficult to access areas.

KOC's initial program also pointed out the need for more dynamic and customized IDI criteria, depending on coating type and for implementing other complementary inspection programs when applicable.

Background

Kuwait Oil Co.'s pipeline network consists of 420 transmission pipelines. OD ranges from 76.2 mm (3-in.) to 1,422.4 mm (56-in.), with length varying from less than 100 m (330 ft) to several kilometers. The network includes lines of various vintages, the oldest commissioned in 1948 and the newest in 2010.

KOC implemented a Total Pipeline Integrity Management System study in March 2005 for its entire pipeline system through NDT Systems & Services, Germany, with Allied Engineers ECDA subcontractors. This included the differential global positioning system (DGPS) mapping of all lines and a baseline, quantitative risk assessment. KOC subsequently prioritized the lines for threat of external corrosion. Following the risk and external corrosion threat assessment, KOC divided the pipeline system into piggable and nonpiggable pipelines. A total of 62% of the KOC pipeline system, representing 261 lines, were nonpiggable.

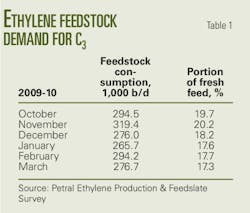

KOC subsequently applied National Association of Corrosion Engineers (NACE) International's External Corrosion Direct Assessment (ECDA) Standard2 to these lines. The ECDA standard outlines a process to assess the integrity of a pipeline subject to the threat of external corrosion. The ECDA process can be applied for both piggable and nonpiggable pipelines as stated under Section 1.1.6 in the NACE ECDA standard.2 Table 1 categorizes the pipelines based on transported products within the KOC system which were initially selected for ECDA.

Since an internal inspection tool could not run through these lines, they were categorized as nonpiggable. The inability to pig these lines could be due to a variety of factors, including the lack of an available launcher-receiver facility or operational and design constraints that may not allow passage of an internal inspection tool.

Direct assessment

Initial application of ECDA requires stringent conditions to be used as an integrity management tool. KOC used the ECDA NACE standard2 as a guide for developing a company-specific ECDA procedure for nonpiggable pipelines within the KOC system. The four prescribed stages of the ECDA program are:

• Preassessment (PrA).

• Indirect inspection (IDI).

• Direct examination (DEx).

• Postassessment (PoA).

Preassessment

This first stage of the process assessed the applicability of ECDA to the KOC pipelines. If preassessment deemed ECDA applicable, available historic and current data were collected and assessed on a per-pipeline basis to define the unique but preliminary ECDA regions. This analysis becomes the base and rationale for development and implementation of the sequential indirect inspection (IDI) surveys and direct examination (DEx) components of the DA process.

Initiating PrA required data from the KOC inspection and corrosion department. Available records consisted of construction and maintenance data, corrosion protection information, and investigative excavation results for some of the lines. For many lines, minimal data were available, with missing data either having been destroyed in the Gulf War or simply no longer available due to the age of some lines. Most of the data were available only in hard copy. Most of the lines also operated under separate asset heads, compounding the difficulty of compiling information to complete the preassessment. A series of discussions and interviews with KOC personnel led to an initial working knowledge of the pipeline system.

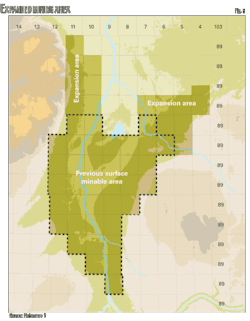

Concurrent to the PrA, NDT, along with Allied Engineers, undertook aboveground DGPS mapping of each pipeline in its system, identifying and documenting information on all aboveground features, crossings, proximity to other lines, and unique right-of-way observations before plotting these data on the most recent geographic information system (GIS) imagery of the system. Fig. 1 displays the generated center line for each of the pipelines.

This process confirmed KOC's pipeline system as being a "spider web network," omitted information related to individual lines, but nonetheless favorable for use of an ECDA process. The baseline DGPS survey allowed line locating, as there were many lines intersecting each other or within a common right-of-way. The PrA program omitted the hundreds of aboveground flow lines included in KOC's system and defined some areas as inaccessible due the presence of oil lakes. The latter instance required extrapolation of the center line position from the nearest two accessible end points.

Dealing with such a large number of pipelines and various data elements required a state-of-the-art GIS-enabled database, flexible enough to allow dynamic data integration as new data were introduced from various PrA and day-to-day pipeline activities. Not all the data collected needed to be electronically saved, but assessing the KOC system required various levels and iterations of data integration and layering.

Allied applied NACE and PRCI data collection guides to all pipelines to assist in the PrA data collection process. Initial prioritization criteria utilized in the preliminary PrA ECDA process applied to all nonpiggable lines consisted of:

• Business critical pipeline (determined by KOC).

• Past failures (known from pipeline records).

• Known data sources, past repairs (known from pipeline records, and also providing a method to evaluate pipelines' ECDA feasibility relative to each individual line).

• Unknown or insufficient data (determined from analysis and lack of available pipeline data).

A series of technical discussions followed the baseline risk assessment, DGPS mapping and baseline mapping, data integration, and the initial PrA, including all involved parties and addressing application of the NACE standard and selection of indirect inspection (IDI) tools. The process required conservative assumptions regarding coating type and material information for each line.

PE-tape coating appeared to be intact on most segments of KOC's system (Fig. 5, photo on left). Further inspection, however, found the coating disbonded and poorly adhered to the pipe surface (Fig. 6, photo on right). |

Per section 3.5 of ECDA standard,2 based on discussions between KOC and Allied Engineers it was decided to treat the lines as a single preliminary ECDA region before selecting two complementary IDI techniques: close-interval potential surveys (CIPS) and direct current voltage gradient (DCVG). KOC approved these techniques, considered traditional IDI survey methods.

Indirect inspection

The second stage of ECDA is aboveground indirect inspection. Proper assessment requires at least two aboveground inspection techniques within each DA region to locate potential external corrosion areas. An established severity criterion prioritized these areas for further action and inspection.

Implementation, quality assurance-quality control, and reporting were the responsibility of another KOC contractor. DCVG and CIPS took place on each of the pipelines considered for the initial program. The DCVG survey used subdecimeter GPS measurements to locate, detect position, and size coating defect indications. Simultaneously, CIPS measured the ON-OFF voltage potentials that were synchronized with GPS controlled current interrupters. Discussions between KOC and the IDI contractor led to a classification index and a priority class (Table 2). Classification categorized each surveyed pipeline into areas requiring immediate (I), scheduled (S), monitored (M), and no further action by KOC.

Direct examination

The third stage of the ECDA process involves excavation, evaluation, and documentation of pipe conditions at an investigative excavation. IDI results guided site selection. DEx assessed actual corrosion found on the pipe body, with results correlated to IDI findings.

PrA and IDI results prompted selection of multiple site locations on each of the program pipelines. These sites included not only areas where immediate action was required but also areas of scheduled and monitored action. Each DEx also included a unique null-site examination for each pipeline at a place where no IDI indications existed.

Validating the ECDA process requires a null-site examination. All DEx sites measured more than a joint length long (roughly 15m) and contained at least one girth weld. This decision enabled proper classification of both the girth weld and pipe coating and allowed for an overall increased inspection sample size.

The KOC pipeline network included pipelines with many types of external coating systems, including coal-tar enamel, asphalt, polyethylene tape, shrink sleeves, three-layer polyethylene, fusion-bonded epoxy, etc., or a combination of multiple coatings on a single pipeline.

Allied Engineers used standardized field procedure for direct examination related to the assessment and documentation of investigative sites for ECDA. Deliverables upon applying these procedures for each DEx investigation included:

• Submeter GPS coordinates of weld locations along with start and end of excavations.

• Correlation of the IDI indication to coating faults, etc.

• Description, documentation of terrain conditions.

• Assessment, documentation of pipeline coating conditions.

• Identification, documentation of pipeline corrosion deposits.

• Documentation of pH values for electrolyte found beneath the disbonded coating.

• When possible, and if required, collection of corrosion deposit, microbial, and electrolyte samples.

• Measuring pipe-to-soil potential at pipe depth, soil resistivity, soil pH, etc.

• Documentation of all defects.

• If necessary, external corrosion defect mapping.

• Engineering analysis as per standards and company accepted procedures.

• Photographs for all of the above.

• Individual site reports followed by a consolidated report for the individual pipeline.

DEx results

• Center line. NDT along with Allied used the submeter GPS reading collected during DEx to regenerate the center line for each pipeline, in some cases observing a center line offset >1 m. Incorrect GPS readings completed during the mapping, typically due to several lines crisscrossing each other in congested pipeline corridors, was the main cause of offsets. Offsets were present in 12% of lines where DEx was performed. GPS coordinates collected during DEx fell within the existing center line generated during mapping for the remainder of the lines.

• Soils. Soils can enhance coating disbondment over time. Most investigative sites lay in areas of fluvial sands, calechie (hard pan), or similar soils. Many locations included both these soils, stratified from the ground surface to the bottom of the excavation. Drainage at these sites ranged from imperfect to well drained. Topography for most sites ranged from level to inclined. Some investigated locations had oil contaminated soils but no unusual or accelerated coating deterioration due to the contaminated soils.

Allied also took soil measurements of resistivity and pH at each investigative site, using the soil characteristics just described to build a quantitative score for soil corrosivity for each investigation.

The majority of lines investigated correlated to both the higher soil corrosivity and a greater coating disbondment. A direct correlation existed in most between soil corrosivity and the number of external corrosion anomalies.

Coating condition

Allied divided the KOC system into two coating types for inspection purposes: coal-tar and tape coating. The investigative locations suggest 65% of the DEx sites contained coal-tar enamel (CTE) coated lines, with the rest coated by polyethylene (PE) tape.

• CTE coated lines. The pipelines inspected had a field applied coal-tar enamel coating and were commissioned between 1952 and 1968. The coating was over the ditch for these lines. As coal tar ages it can become brittle, which may affect its physical protective properties and cathodic compatibility. At most of the sites the outer wrap (applied to hold the molten coal tar in place) appeared to be bonded as displayed in Fig. 2, with the coal-tar coating underneath disbonded and poorly adhered to the pipe surface as illustrated in Fig. 3.

The coal-tar coating was cohesive but in many cases poorly adhered to the pipe surface. Allied compared the percentage of disbonded coating to the IDI severity classification accepted by KOC (Fig. 4), identifying a correlation between the IDI priority class and disbonded coating. The most severe disbondment was in immediate action-required sites, with coating conditions improving as the severity class moderated.

At most of the sites in KOC's system where pipe had been treated with coal-tar enamel, the outer wrap (applied to hold the molten coal tar in place) appeared to be bonded as new (Fig. 2, left photo), but the coal-tar coating underneath was often disbonded (Fig. 3, right photo). |

• PE-tape coated lines. The pipelines inspected used field-applied, single-wrap polyethylene tape coating and were commissioned 1970-73. A major concern with tape coating systems surrounds their compatibility with cathodic protection. If the coating disbonds, CP's ability to protect the pipe surface from external corrosion is severely limited. In most locations the PE-tape coating visually appeared to be intact (Fig. 5). Further inspection, however, found the PE tape coating disbonded and poorly adhered to the pipe surface (Fig. 6). Extensive corrosion deposits existed under the disbonded coating.

Allied again compared the extent of disbonded PE-tape coating to the IDI severity classification, in this case finding no correlation (Fig. 7). In many cases the immediate-need locations had better coating than the lower prioritized sites.

External corrosion

Technicians consistently found corrosion deposits of iron oxide/hydroxide (FeO/OH), commonly known as rust, under the disbonded coating. Many areas also held deposits of calcium carbonate (CaCO3), indicative of a functioning cathodic protection system, and iron carbonate (FeCO3) associated with anaerobic conditions, with both leading to external corrosion.

Pitting corrosion commonly lay under the FeO and FeCO3 corrosion deposits, consisting of both localized general wall loss with associated pitting and isolated pits. Figs. 8 and 9 categorize the external corrosion anomalies detected for both coal-tar and polyethylene tape systems based on the severity of IDI indications. A correlation exists between the number and severity of anomalies associated with the coal-tar coatings and existing IDI classification. For polyethylene-tape coating, however, no correlation was found.

The defect engineering assessment was guided by ASME B31G, Modified B31G and Effective Areas Method. Each anomaly received a Pass/Fail classification based on ASME B31G, which was a KOC requirement.

An engineering schematic generated for each investigative site, displayed the correlation of IDI indications, disbonded coating, and color-coded anomalies based on Pass/Fail classification. Analysis also generated graphical representation and detailed calculations for failed anomalies. Other anomalies found during DEx—gouges, dents, pins, arc burns, microbiologically influenced corrosion, etc.—were also documented.

Postassessment

After completing the three ECDA stages, KOC inspection and corrosion performed the PoA and continues to perform an iterative review based on the ECDA program on a line-by-line basis. The ECDA program forms a portion of the overall KOC integrity-management program, and led to the following actions:

• Line being declared unfit for service.

• Immediate repairs, development of future repair plans.

• Complete line coating rehabilitation.

• Performing mechanical modifications to make the line piggable for further inspection.

• Performing a hydrotest.

• Revising, rerating the operating pressure.

• Determination of the next ECDA program for these lines in this program and future lines.

• Data integration based on the ECDA steps, improvement of system-wide integrity management practices.

• Rerunning risk assessment, reranking lines.

• Developing pipeline performance metrics.

Acknowledgments

The authors acknowledge the assistance of KOC inspection and corrosion department, NDT Systems & Services, Allied Engineers inspection team, and Marr Associates in completing this article.

References

1. Standard Practice ANSI/NACE SP0502-2008 "Pipeline External Corrosion Direct Assessment Methodology," NACE International, 2008.

2. Pipeline Research Council International ECDA Standards[more information needed].

3. Peabody, A.W., "Peabody's Control of Pipeline Corrosion," Second Edition, Houston: NACE International, 2001.

The authors

Ashish Khera ([email protected]) is working as a director at Allied Engineers, New Delhi. He has also served as a pipeline integrity engineer at Marr Associates, Canada. He holds a degree in petroleum engineering (2001) from University of Alberta. He is a member of APEGGA, NACE, and ASME.

Jim Marr ([email protected]) is currently SCC program planning manager for TransCanada Pipelines, Calgary. From 1992 to 2008, he was president of Marr Associates, pipeline integrity consulting firm. He graduated with a degree in earth sciences (1986) from the University of Guelph, Ontario. He is a member of ASME, NACE, and was a past vice-chair of the NACE SCCDA committee.

Shabbir Safri ([email protected]) is working as specialist-inspection at Kuwait Oil Co., Kuwait. He has also served as deputy manager-inspection at Bharat Petroleum Corp., India. He holds a degree in mechanical engineering (1982) from South Gujarat University, India.

Abdul Wahab Al-Mithin ([email protected]) is working as team leader, inspection and corrosion, south and east, at Kuwait Oil Co. He holds a degree in metallurgical engineering from the University of Utah. He is a member of NACE.

Saleh Al-Sulaiman ([email protected]) is working as team leader, inspection and corrosion, north and west, at Kuwait Oil Co. He holds a degree in mechanical engineering from Kuwait University. He is a member of NACE.

Differential global positioning system mapping of each pipeline in Kuwait Oil Co.'s system identified and documented information on all aboveground features before plotting these data on the most recent geographic information system (GIS) imagery of the system and generating center lines for each pipeline (Fig. 1).

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com