New correlation predicts dewpoints of acidic combustion gases

A newly developed general correlation accurately predicts acidic combustion gas dewpoints to mitigate corrosion potential in pollution control and energy-recovery equipment.

Acidic combustion gases can cause rapid corrosion when they condense on the surfaces of heat recovery and flue-gas-treatment equipment. This investigation considered the most important acidic gases—SO3, SO2, NO2, hydrochloric acid, and hydrobromic acid.

The correlation can accurately predict flue-gas acid dewpoint temperatures over wide ranges of acid and water-vapor concentrations in oil and gas operations.

Condensation, corrosion

Acid dewpoint corrosion results from condensation of flue-gas acid species on low temperature gas-path surfaces. This kind of corrosion differs from general atmospheric corrosion and causes heavy corrosion not only of ordinary steels but even stainless steels.1

Corrosion failures often occur because of condensing flue gases containing SO3, SO2, NO2, HCl, HBr, and H2O. Dewpoint temperature is a function of the water vapor concentration and the concentration of acid species in the flue gas.2 The condensed acids are corrosive to steel and almost all plastics, as well as hydraulic cement composites.

Further, gas cooling below this dewpoint by radiation or convection forms a mist of corrosive acid droplets that is highly detrimental to the stack and heat-recovery equipment.3 Many of the processes for improving the thermal efficiency of combined-cycle plants can also result in lower flue-gas temperatures leaving the heat-recovery steam generators or increased flue-gas moisture content. These conditions can increase the potential for corrosion of the low-temperature gas-path components.4

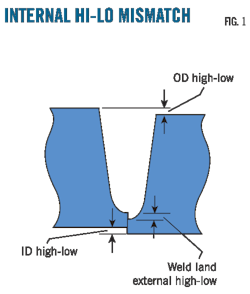

Fig. 1 shows sulfuric acid and hydrochloric acid dewpoint corrosion occurring in a typical flue-gas treatment system of a waste-incineration plant. For a typical flue gas (SO3 = 3 ppm (vol); HCl = 300 ppm (vol); H2O = 30 vol %), the H2SO4 and HCl dewpoints are about 136° and 72° C., respectively (Fig. 1).

At temperatures of 72-136° C., the H2SO4 condensation is the main cause of steel corrosion failure. Improvement of the thermal efficiency of flue-gas treatment equipment may need further cooling to a temperature as low as 72° C. As Fig. 1 shows, at flue-gas temperatures cooler than 72° C., HCl condensation is also an important influence in corrosion failure.

Verhoff and Banchero provided the correlation for predicting flue-gas sulfuric acid dewpoint shown in Equation 1 of the accompanying equations box.5 The correlation does not apply to halogenated or nitrated acid gases.

To overcome this shortcoming, Kiang proposed different correlations for estimating NO2, HCl, and HBr dewpoints.6 There are usually significant deviations, however, between predicted and experimental dewpoints over the concentrations prevailing in combustion gases.

It should be noted that there is some disagreement between the experimental data and the Verhoff and Banchero correlation, especially at low acid concentrations and high H2O content. Dewpoints predicted in the range of 120-140° C. have a positive deviation of 4° C. and more. Also in the range of 100-121° C., the predicted dewpoints are usually 4° C. low.

Okkes proposed a correlation (Equation 2) to overcome some of these shortcomings.7 Although this correlation is more accurate at H2O concentrations higher than 25%, it significantly underpredicts the sulfuric acid dewpoints at low H2O concentrations that prevail in oil and gas operations.

Since these correlations are not accurate enough for proper design of combustion equipment and heat-recovery systems, this article proposes a general correlation for accurate prediction of the most important acid-gas dewpoints.

Proposed correlation

This proposed general correlation is based on verified experimental data for accurate prediction of flue-gas acid dewpoints. A set of 940 dewpoint temperatures is determined for the most important acidic gases—SO3, SO2, NO2, HCl, and HBr—by using the most accurate vapor-liquid equilibrium data.8-11 We have found that this general correlation—Equation 3—can be used for accurate prediction of the dewpoints of acidic combustion gases.

It should be noted that Ai, Bi, Ci, and Di parameters do not depend on acid species and are always fixed. The parameter λ and molecular weight (Mw) are given for the relevant condensed acid. Tables 1 and 2 display the optimum values of all parameters determined by the genetic algorithm.12

With the parameters displayed in Tables 1 and 2, Equation 3 yields the smallest sum of the squared errors for the entire range of acid dewpoint temperatures. The following section elaborates the performance of the proposed correlation.

Comparisons

Fig. 2a shows results of comparing predicted flue-gas sulfuric acid dewpoints by using Equation 3 with experimental data at different acid and moisture concentrations. Firing fossil fuels that contain sulfur in heaters or boilers yields sulfur dioxide and, to a lesser extent, sulfur trioxide as well as carbon dioxide and water vapor.

The SO3 combines with water vapor in the flue gas to form sulfuric acid and condenses on heat-transfer surfaces, a process that could lead to corrosion and destruction of the surfaces. This condensation occurs on surfaces that are at or below the dewpoint of the acid gas.

As shown in Fig 2a, because the acid dewpoint is very sensitive to the flue-gas SO3 concentration, a small increase in SO3 concentration leads to a large increase in sulfuric acid dewpoint at a given H2O concentration. The moisture content is also an important influence. As the moisture concentration increases, however, the effect of vapor H2O on sulfuric acid dewpoint gradually reduces.

Since the sulfuric acid formed through the reaction of SO3 and H2O in the flue gas is usually condensed at relatively high temperatures, the corrosion risk in the waste-heat-recovery system is too high. As shown, the vapor-phase sulfur trioxide concentration strongly influences flue-gas dewpoint especially at SO3 concentrations less than 100 ppm (vol).

Thus the accurate prediction of sulfuric-acid dewpoints at low SO3 concentrations prevailing in process industries is important in controlling the corrosion problems in thermal waste-treatment plants and energy-recovery equipment. In most installations, formation of sulfuric acid is prevented by keeping the temperature above sulfuric acid's dewpoint as much as possible.

Fig. 2b compares predicted and measured flue-gas sulfurous acid dewpoints. The diagram shows sulfurous acid's condensation temperature is mainly influenced by water-vapor concentration. Since sulfurous acid is always formed through the dissolution of SO2 in condensed water at lower than the water dewpoint, the corrosion risk in the stack is lower, compared with that for sulfuric acid.

Sulfurous acid formation at temperatures around 60° C., however, accelerates metallic corrosion in heat-recovery systems. The trend of dewpoint variation with respect to the moisture content is similar to the case of sulfuric acid in that the H2O content is less influential at higher moisture concentration. According to Fig. 2b, the sulfurous acid dewpoint temperature is always less than 70° C. as long as the moisture concentration is no higher than 30 vol %.

Fig. 2c compares predicted flue-gas nitric acid dewpoints, using the proposed correlation, with experimental data at different acid and moisture concentrations. The NO2 condenses as nitric acid below the nitric acid dewpoint or it dissolves in the condensed water below the water dewpoint to form nitric acid solution, causing severe stress corrosion cracking. In a gas containing 50 ppm (vol) NO2 and 5 vol % water (a typical high NO2 containing combustion gas emitted by a gas-turbine power station), the NO2 dewpoint (28° C.) is lower than the water dewpoint (33° C.).

During operation of the heat-recovery steam generator, the inlet temperature is at least 70° C., which excludes water and nitric acid condensing. In this case, only during shutdowns, nitric acid can be formed by gas dissolution in the water droplets.

At high flue-gas NO2 concentrations, the NO2 dewpoint is usually higher than water dewpoint so that the nitric-acid condensation takes place directly from the gas phase below the nitric acid dewpoint. Fig. 2c shows that predicted nitric-acid dewpoints are in good agreement with experimental data.

Figs. 2d and 2e compare predicted flue-gas hydrochloric and hydrobromic acid dewpoints, by use of the proposed correlation, with measured data at different acid and moisture concentrations, respectively. In municipal solid-waste-fired plants, in addition to sulfuric acid, one must deal with hydrochloric and hydrobromic acid formation.

Also the halogenated compounds used in various types of plastics are released in waste incinerators so that the dewpoint corrosion due to HCl or HBr condensation may take place. Similar to the previous cases, the effect of H2O concentration on acid dewpoint is more important at low moisture concentrations, as shown in Figs. 2d and 2e. According to these figures, the flue-gas hydrochloric and hydrobromic acid dewpoints are usually less than 80° C. in most practical cases. Figs. 2d and 2e show predicted results are in good agreement with experimental data.

Fig. 3 compares Equation 3 with Verhoff and Banchero (Equation 1) and Okkes (Equation 2) correlations regarding prediction of sulfuric acid dewpoints at a moisture concentration of 20 vol %. It shows that the V.B. correlation leads to considerable acid dewpoint overprediction. In such a case, the operator may incorrectly increase the air preheating level to combat the cold-end corrosion problem.

On the other hand, using the Okkes correlation leads to a large dewpoint underprediction, so that the air preheating level may be inadequate to overcome the corrosion risk.

The dewpoints predicted by Equation 3 are much more accurate than those predicted by V.B. and Okkes correlations and are in excellent agreement with measured acid dewpoints (Fig. 3).

Accurate prediction of flue-gas acid dewpoint is important for optimizing energy consumption in combustors and incinerators.

Table 3 gives deviations between predicted and measured acid dewpoints. The average absolute deviation in sulfuric acid dewpoint predictions is about 0.5541%, smaller than those of the other acids. Since the sulfuric acid dewpoint is usually higher than those of the other acids, it is important to predict the H2SO4 condensation temperature accurately.

In fact the sulfuric acid dewpoint temperature is the main bottleneck for increasing the performance of heat-recovery systems. The overall average absolute deviation, root mean square deviation, and correlation coefficient values regarding the proposed correlation are about 1.055%, 0.9815, and 0.9994, respectively. These suggest that Equation 3 is accurate enough for predicting the dewpoints of the different acid gases.

Fig. 4 also compares the predicted flue-gas acid dewpoints, according to Equation 3, with all available experimental data regarding all aforementioned acid gases. As shown, the proposed correlation can be used for accurately predicting the flue-gas acid dewpoint temperatures over wide ranges of moisture and acid gas concentrations.

Acknowledgment

The author thanks National Iranian Gas Co. for its cooperation during preparation of this article.

References

1. Rockel, M.B., and Bender, R., Corrosion Handbook, Frankfurt: Society for Chemical Engineering and Biotechnology, 2008.

2. Blanco, J.M., and Pena, F., Applied Thermal Engineering, Vol. 28, No. 7 (2008), pp. 777-784.

3. Cherif, M., Mgaidi., A., Ammar, M.N., Abderrabba, M., and Furst, W., Fluid Phase Equilibria, Vol. 194 (2002), pp. 729-738.

4. Lins, V.F.C., and Guimaraes, E.M., Journal of Loss Prevention in the Process Industries, Vol. 20 (2007), pp. 91-97.

5. Verhoff, F.H., and Banchero, J.T., Chemical Engineering Progress, Vol. 70 (1974), pp. 71-72.

6. Kiang, Y.H., Chemical Engineering, Feb. 9, 1981, p. 127.

7. Okkes, A.G., Hydrocarbon Processing, July 1987, pp. 53-55.

8. Technical document, Tokyo: Nippon Oil Co., 2008.

9. Perry, R.H., Green, D.W., and Maloney, J.O., Chemical Engineers Handbook, 7th edition, New York: McGraw Hill, 1999.

10. Ullmann's Encyclopedia of Industrial Chemistry, 6th Edition, Weinheim, Germany: Wiley-VCH Verlag GMBH & Co. KGaA, 2001.

11. Gmehling, J., Menke, J., Krafczyk, J., and Fischer, K., Azeotropic Data, 2nd Edition, Weinheim, Germany: Wiley-VCH Verlag GMBH & Co. KGaA, 2004.

12. Goldberg, D.E., Genetic Algorithms in Search, Optimization, and Machine Learning, Addison Wesley, 2007.

The author

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com