Proper method boosts decommissioned pipe value

David Howell

Pipeline Equities

Houston

Pricing decommissioned line pipe above scrap requires proper valuation methods and handling. Contractors and equipment operators who fail to understand the potential value of good structural grade steel pipe can inadvertently reduce its potential market price to what it will bring at the local scrap yard.

The standard formula for determining the overall value of a pipeline that has throughput uses the net operating income multiplied by a time life number, e.g., $450,000 × 10 years = $4,500,000. The Replacement Cost New method offers an alternative valuation based simply on the replacement cost of the pipeline at today's cost depreciated to reflect the age of the subject pipeline property.

This method accounts for the construction and acquisition costs associated with replacing the old pipeline with a completely new pipeline. Circumstances exist that, due to demand and scarcity, will elevate an easement, corridor, or right-of-way to greater worth than the 70 or 80-year old pipeline lying within it.

Salvage value determinants vary depending on the market. Almost all steel-related markets are weighted by the price of scrap at one time or another. One barometer for determining the value of good used pipe is to give it a worth based on 70% of the price of new similar pipe. This is the highest price for used pipe and is normally the price to an end user.

Several layers of wholesale lie between the end user and the salvage operator on the track hoe on a right-of-way somewhere in New Mexico. These layers include hauling, grading, straightening, cleaning, beveling, cutting, loading, trucking, and selling of the pipe. An entire line might be sold to one distributor who then resells in truckload quantities to others who might sell by the piece. Each level of sale has a different price for a unique utility, and each level has a specific type of buyer.

At its base, pipe from the pipeline is just a tubular form of steel and is used in the same manner. The goal is to climb as high up the sales chain as possible to get the most value for your product. A salvage operator can get to the 50%-of-new level and still leave 20% for distributors who deliver to end users and deal with credit, collections, warranties, and other problems associated with the retail sales.

Method

Pipeline for structural use is measured by weight on a per-ton basis. Millions of feet of vintage pipeline are available in the US of 8.625-in. OD and lap-weld construction (similar to butt weld). Lap welding starts with a sheet of steel that is then rolled into a tubular shape and welded at the point where the ends lap. Almost all the pipe laid in the 1920s and 30s for oil transportation was of lap weld construction, and almost all of these had a uniform 0.322-in. WT.

This type of pipe weighed 28.55 lb/ft and was called "standard wall" because it was the standard WT for line pipe used in transporting oil. Joints usually measured 20 ft long because this length fit easily on the mule-pulled wagons distributing pipe along the right-of-way.

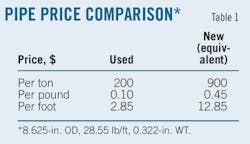

A scrap price for long iron (pieces of pipe longer than 3 ft) of $200/ton for example, places the value of standard wall pipe at $0.10/lb. The 28.55 lb/ft standard wall pipe is therefore worth a minimum of $2.85/ft, its price at the scrap yard. Scrap establishes minimum worth and the price of new pipe at the mill represents the opposite end of the spectrum. The mill price might be $900/ton or $0.45/lb ($12.85/ft using the same calculations). Table 1 shows price comparisons.

Somewhere in this price range lies the pipe value for reuse for structural purposes. Value can also be added at different stages along the sales chain. One wholesaler might cut the pipe into 10-ft lengths and bevel or end finish each end of the pipe. Another might weld two lengths together to make a 35-ft joint for use in a particular piling job requiring that length. Other structural uses might include corrals, fence posts, flagpoles, bridge railings, cattle guards, or even reuse as a pipeline or driven as pile for strengthening supports.

One yard in Oklahoma uses 22-in. OD line pipe by splitting it longitudinally and welding plate on the sides to make feed troughs for cattle feed lots, satisfying a healthy demand for many years for this product. All of these items are worth a great deal more than scrap.

Factoring in net value requires considering the following costs among several related to pipe removal:

• Purchase of the material.

• Excavation costs.

• Hauling.

• Landowner compensation.

• Crop damages.

• Administration expenses.

Table 2 provides an overview of additional costs to factor into the net value of used pipe. These costs come to $2.60/ft, very close to break-even at scrap values. But scrap should only be viewed as backup in case there is no structural market. That being said, a unqualified track hoe operator can make scrap out of the best pipe ever laid, dinging, denting, scraping, and bowing the pipe into junkyard iron.

A shortcut providing a rough estimate of used pipe value is: (Sell Price – Costs) × Line Length × 90%. If the seller can move the used pipe for $400/ton ($0.20/lb, $5.71/ft), subtracting the take-up and cleaning costs, the pipe might be worth a net of $2.25/ft. Subtracting 10% for losses and damage yields a value of $2.00/ft after removal.

Transportation

As of June 2010 trucking costs to bring pipe to Houston to be cleaned, straightened, cut, rewelded, or worked in any way for the purpose of exporting through the Port of Houston was about $1.75/ loaded mile. Rates can vary from $1.50 to $2.25/loaded mile.

Cleaned, double-jointed 8-in. OD pipe formed from single random lengths stands ready for additional service (Fig. 1).

Pipe condition

Surveying the pipeline by riding the length of it and looking for such unforeseen hazards as lakes, rivers, expensive crops, marshland, wildlife refuge areas, other environmentally sensitive areas, and encroachments of all kinds, also must occur as part of determining costs. A home, barn, or trailer may have been built over the right-of-way.

In such instances a qualified inspector must dig a bell hole over one section of the pipe to confirm it is there, verify the depth at which it is buried and its size, and determine its condition. A sample of the coating can indicate its composition, particularly important because asbestos' presence can affect removal costs (Fig. 2).

An inspector inside a bell hole checks a decommissioned line's exterior, WT, coating type, burial depth, and soil conditions (Fig. 2).

Steel composition

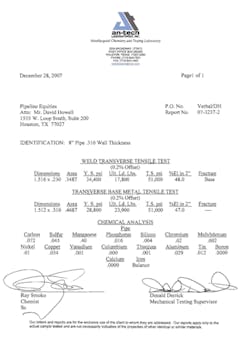

Pipe steel type and quality are important factors in determining the integrity of the pipe. Cutting a section or coupon of the pipe and sending it to a lab allow testing for yield or burst strength as well as tensile strength or hardness. Additional tests can determine the various chemical elements in the steel (Fig. 3).

Lab reports on submitted pipe samples can determine a pipe's metallurgy prior to excavation (Fig. 3).

The author

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com