Revising CP criteria requires careful consideration

Criteria to demonstrate levels of cathodic protection are important but should not be the only consideration during the ongoing review of NACE SP 0169, the association's document covering external pipeline corrosion.

When choosing a CP plan, a company must not limit itself to only one criterion but use all available methods available to prove it is adequately controlling external corrosion.

Training those responsible for taking and interpreting pipe-to-soil potentials to recognize when a particular potential may be inadequate is more critical than requiring everyone to use a more stringent cathodic-protection criterion at all locations along a pipeline, especially since a particular criterion might work well for one system but less so for another.

The "ON" –850 mv criterion (with and without voltage-drop consideration) has successfully and economically mitigated corrosion for many years around the world, yet some wish to remove it from current standards. The polarized –850 mv criterion is conservative, expensive, has potentially detrimental issues that must be considered, and is impossible to use on many pipeline systems. The 100-mv polarization criterion is difficult to use but provides an excellent way to measure adequate protection on systems incapable of achieving either of the other two criteria.

No matter what criterion is chosen by the pipeline company, external corrosion can continue when nonshielding pipeline coatings are used.

Background

One of the biggest problems surrounding cathodic protection (CP) of pipelines and related structures is determining when CP is adequate. Voltage measurements typically occur on the surface of the electrolyte (soil, water, etc.) and are interpreted to determine the CP's effectiveness. But different opinions exist regarding the proper way to determine adequate cathodic protection.

NACE International is the leader in developing industry standard practices for many corrosion control processes. Its SP 0169, "Control of External Corrosion on Underground or Submerged Metallic Piping Systems," was its first standard and has been revised several times since being introduced in 1969, with controversy often surrounding its CP criteria. NACE International's TG 360 group is once again in the process of revising the entire document.

CP criteria

Chapter 1 of NACE's "Concept of Cathodic Protection," Cathodic Protection Level 3 Training Manual, 2000" states "corrosion occurs where metal atoms give up electrons that produce electron flow (negative current flow) away from the area and positive ions (corrosion products). The objective of cathodic protection is to force the entire surface to act as a cathode so there is no electrical potential to cause the electrochemical reaction and, therefore no corrosion occurs. The application of direct current to a corroding metal can cause it to become entirely cathodic."

Because, however, there are no practical ways to measure this criterion, the industry uses a variety of voltage measurements and techniques to determine if adequate cathodic protection is being provided.

The basic three used today in accordance with SP 0169-20071 are:

• 6.2.2.1.1—A negative (cathodic) potential of at least 850 mv with the CP applied. This potential is measured with respect to a saturated copper-copper sulfate reference electrode contacting the electrolyte. Voltage drops other than those across the structure-to-electrolyte boundary must be considered for valid interpretation of this voltage measurement.

• 6.2.2.1.2—A negative polarized potential of at least 850 mv relative to a saturated copper-copper sulfate reference electrode.

• 6.2.2.1.3—A minimum 100 mv of cathodic polarization between the structure surface and a stable reference electrode contacting the electrolyte. The formation or decay of polarization can be measured to satisfy this criterion.

The debate

External corrosion control involves several aspects, not just CP and its criteria. Given proper engineering, selection, and application of corrosion control measures such as coatings, less CP is required, yet CP and its criteria are the focal point of many discussions and issues surrounding SP 0169.

Perhaps no other issue pertaining to the application of cathodic protection is subject to as much controversy and discussion as the various protections either in common use or contained in industry standards.2 CP practitioners generally have become overly concerned about perceived but actually non-existent serious IR drop problems in typical pipe-to-soil potential measurements at test lead locations on a buried steel pipeline.3

Most of the controversy surrounds the first criterion, 6.2.2.1.1. Many in the pipeline industry have used and continue successfully to use an "ON" –850 mv criterion. The problems here involve the importance of considering voltage drops. Some hold such consideration as absolutely necessary, while others do not consider it necessary in most environments. Considering or measuring voltage drops can be time consuming and expensive.

Direct-current voltage gradient (DCVG) in the soil stems from CP current flowing through the soil onto the pipeline and verifies that corrosion current cannot be flowing from the pipe into the soil to corrode the pipeline at this test location and CP is complete. No consideration for IR drop is necessary.3

"When the amount of current flowing (to the pipe) is adjusted properly, it will overpower corrosion current discharging from all anodic areas on the pipeline and there will be a net current flow onto the pipe surface at these points. The entire surface will then be cathodic and the protection complete."4

External pipeline corrosion control has seen great change over the years from a regulatory standpoint but few advances in technology to assist in monitoring mitigation's effectiveness.5 One in-line-inspection (ILI), however, can now determine if current is being picked up or discharged from the pipe at the sites where coating holidays are present or there are coatings that are nonshielding to the CP current where disbondments have occurred.

'ON' –850 mv

The "ON" –850 mv or more negative potential is the most frequently used of the various criteria and has much support for continued use. The most critical discussion involves whether to use an "ON" –850 mv with or without consideration of voltage drop. The most frequent use of this criterion has occurred without consideration of voltage drop. Others insist the voltage drop must be considered for a valid interpretation of this criterion.

Several studies have sought to determine when and if it is necessary to determine voltage drop. One such study was performed during the standard's revision process in the late 1980s and early 1990s to provide information showing that when the "ON"-850 mv criterion is in use, the voltage drop is not enough to cause concern in most cases.

The study included Transco, United Gas, Piedmont Natural Gas, Enron, and Mobil Pipeline among its participants and showed that when the "ON" potential is –850 mv or more negative, there will also be at least 100 mv of polarization. There may be locations where this is not true, but the study shows these instances to be rare even in high resistivity soils.

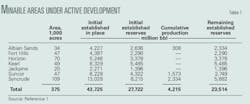

Table 1 summarizes and shows potentials taken in a variety of soil resistivities, pipe sizes, and locations.

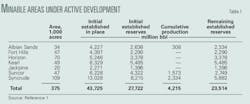

Table 2 shows potentials taken in areas where the ON potentials are more positive than or close to –850 mv, yet 100 mV of polarization is achieved at all these sites. These two tables show that when an "ON" –850 mv or more negative criterion is being used, consideration of voltage drop is not always required.

Several other factors also suggest an "ON" –850 mv without voltage drop consideration as being a sufficient criterion in nearly all instances, including:

• Those companies that use the "ON" criterion without considering voltage drop hold their "ON" potentials at values more negative than a –850 mv, thereby allowing for voltage drops. To hold all "ON" potentials at –850 mv is impossible on structures such as pipelines because of the variety of electrolyte exposures, coating conditions, pipe sizes, WT, and other variables.

The "ON" –850 mv is the guideline for showing areas for which more testing and possibly more protection are needed. This uncomplicated method allows companies to use their personnel and resources efficiently and effectively to protect their pipeline systems.

• Fusion-bonded epoxy coatings have been used for 50 years without the external corrosion problems experienced during use of most other types of coating. FBE is one of the few coating systems that are "nonshielding" to CP when a coating disbondment occurs. A "nonshielding" coating allows CP current to reach the pipe and eliminate or reduce any corrosion on the pipe under the coating. Only a few other coatings have this property. The US Department of Transportation states in one of its new regulations that a coating system must be nonshielding.

• Studying the actual field data from the thousands of miles of close-interval surveys performed on pipelines can determine what percentage of the time the 100 mv of polarization criterion is achieved when the "ON" potential is –850 mv or more negative. This is nearly 100% of the time, as shown by Tables 1 and 2.

Of 133 potential readings provided by surveys on various pipelines around the US by different pipeline companies, all were able to show at least 100 mv up to 1,500 mv (close to the rectifier) polarization. "ON" potentials ranged from –420 mv to beyond –2,000 mv. Most of these "ON" potentials were more positive than –850 mv and were on poorly coated pipelines.

That 100 mv of polarization can be attained on pipelines with "ON" potentials more positive than –850 mv leaves open the question of why 100 mv of polarization cannot be reached when the "ON" potential is a –850 mv or more negative, especially when the pipelines are well-coated. Soil resistivity around these pipelines ranged from 260 ohm-cm to 1,000,000 ohm-cm, showing it is not always a reason for excessive voltage drop.

The –850 mv criterion was based on empirical observation that corrosion was stopped on pipelines when the measured potential (without correction for IR drop or without using close interval surveys) was –800 mv or more negative.6 As with all criteria, there are times when the "ON" –850 mv may not be the best option. Better training of our CP technicians and engineers to be aware of areas potentially requiring more CP or use of a different criterion is the best approach to this problem.

Polarized –850 mv

The polarized –850 mv criterion is conservative and will typically provide the most current to the pipeline. Several issues surrounding this criterion must be addressed. The polarized –850 mv criterion (6.2.2.1.2) involves attempting to measure the polarized potential of the structure. Correctly measuring a polarized potential requires interrupting all DC power sources affecting the potential at the same "instant" to derive the "polarized" or "instant off" potential.

It is important to use a consistent measurement technique. The variety of instruments and techniques used to measure "instant off" potential are all subject to operator error and interpretation.

It is also difficult to interrupt all power sources potentially affecting a pipeline's potential reading. Sophisticated interrupters synchronized to satellite clocks can interrupt all sources within a few milliseconds of each other, helping eliminate many of the problems from the past of having interrupted cycles fractions of a second or more apart.

Once the instruments are chosen, all power sources affecting the potentials must be identified. This is easy on new, well-coated pipelines in single pipe right-of-ways, but difficult in multiple-pipeline ROW where unknown underground bonds, galvanic anodes, and other such current sources are possible. Just the voltage difference between bonded pipelines, especially when some are coated and some are not, can create potential differences capable of causing errors in potential readings.

Most of the studies provided in defense of using the polarized –850 mv criterion detailed experiments performed on coupons, not pipelines. Some of the testing on coupons occurred in laboratories. Coupons are a viable test method to help determine the corrosion process and protective levels, but they do not always represent pipelines in their various environments. The best data still come from pipelines, not a coupon in a lab or artificial environment.

Caution must be used when employing a polarized potential criterion. Meeting the polarized –850 mv criterion on long pipelines requires increasing the current, which in turn increases cost, survey time (for instant off readings), the number of CP systems to be installed, and energy used. The potential exists for increased CP interference on foreign pipelines and other metal objects in the area. The greater current used under the polarized –850 mv criterion also potentially increases problems with coating disbondments, stress corrosion cracking, and hydrogen damage to high-strength steel pipelines.

Awareness has increased regarding possible damage caused by applying cathodic protection to high-strength steels and corrosion resistant alloys.7 In practice, the "850 Polarized" criterion is generally more conservative, requires more cathodic-protection current, involves the use of more sophisticated equipment and potential measurement techniques, and is therefore more costly than using the "850 On" criterion.8

100 mv criterion

Making all surfaces of the protected structure as negative as or more negative than the most negative (anodic) site on its surface will provide full cathodic protection. Achieving this criterion makes the entire surface a cathode receiving current from the CP system, preventing conventional current discharge from the pipe into any electrolytes and eliminating corrosion problems.

Reducing current capacity demand by using the 100 mv polarization criterion, when appropriate, will reduce the probability of stray currents and cut operating power and capital costs.9 This criterion requires the least amount of cathodic protection current, and once 100 mv of polarization is achieved, the "ON" potential (or one more negative) can be relied upon unless major changes are made to the CP system or the pipe and coating, thereby reducing annual survey costs.

Adding a safety factor of 100 mv of polarization ensures adequate protection despite the inability to measure all areas on the surface of a pipeline. The criterion, however, requires taking instant off readings to find the polarized potential of the structure, after which it can be compared to the native potential (the potential of the pipe before any CP is added).

Companies must often perform a depolarization survey to determine if there is at least 100 mv polarization, since most pipelines do not have native potentials established. The 100 mv or more of polarization can therefore be established by subtracting the native from the polarized potential or from showing at least 100 mv depolarization from the polarized potential.

One mistake some companies make in using this criterion is leaving power sources off for extended periods of time. One should normally be able to establish the 100 mv of polarization in 72 hr, but there is no set time established that is correct for each system. The real hazard lies in the potential for corrosion from interference while the pipeline is unprotected trying to achieve the 100 mv.

Corrosion continues

No matter which criterion is used, there will continue to be external corrosion on pipelines.10-20 Most external corrosion on cathodically protected pipelines today is not due to inadequate CP levels but is instead caused by disbonded coatings shielding the cathodic protection (Figs. 1-2). Shielding of CP from rocks and other natural formations prevents the current from reaching the pipe at coating holidays. AC and DC interference is another serious cause of external corrosion; this problem will increase if companies are forced to use the polarized –850 mv criterion.

Certain coating types produce CP shielding when disbondments occur allowing water to enter between the coating and the pipe. This water incursion sets up an isolated corrosion cell under the coating, not allowing enough CP current to protect the pipe (Fig. 3). Corrosion rates depend on the type and amount of electrolyte, availability of oxygen and other corrosion accelerating contaminates, and whether this electrolyte is exchanged.

References

1. NACE International SP0169, 2007.

2. Gummow, R.A., "Cathodic Protection criteria—A critical review of NACE Standard RP-01-69," Materials Performance, Vol. 25, No. 9, September 1986, pp. 9-16.

3. Bash, L.A., "Pipe-to-soil Potential Measurements, the Basic Science," NACE Corrosion 2008, New Orleans, Mar. 16-20, 2008.

4. Peabody, A.W., "Control of Pipeline Corrosion," NACE International, Houston, 1967.

5. Janda, D., "Cathodic Protection—It's All About Current," NACE Corrosion 2010, San Antonio, Mar. 14-18, 2010.

6. Ondak, E.J., and Rizzo, F.E., "Electrochemical Analysis of Pipeline CP Criteria," NACE Corrosion 2008, New Orleans, Mar. 16-20, 2008.

7. Billingham, M., and John, G., "Determining the Compatibility of High Strength Steels to Cathodic Protection," NACE Corrosion 2008, New Orleans, Mar. 16-20, 2008.

8. Trimble, W.L., "What's Right with 850 ON, What's Wrong with 850 Polarized, How We Can Improve Them Both," NACE Corrosion 2010, San Antonio, Mar. 14-18, 2010.

9. Trimble, W.L., "The Use of the 100 mv Polarization Criterion in Cathodically Protected Facilities," NACE Corrosion 2008, New Orleans, Mar. 16-20, 2008.

10. Ruschau, G.R., and Chen, Y., "Determining the CP Shielding Behavior of Pipeline Coatings in the Laboratory," NACE Corrosion 2006, San Diego, Mar. 12-16, 2006.

11. Moore, D.P., "Cathodic Shielding Can Be A Major Problem After A Coating Fails," Materials Performance, Vol. 39, No. 4, April 2000, p. 44.

12. Beavers, J.A., and Thompson, N.G., "Corrosion Beneath Disbonded Pipeline Coatings," Materials Performance, Vol. 36, No. 4, April 1997, p. 36.

13. Norsworthy, R., "Select Effective Pipeline Coatings," Hart's Pipeline Digest, February 1997, p. 17.

14. Pfaff, T.A., "FBE Serves a Broad Market," Hart's Pipeline Digest, October 1996, p. 2.

15. Kehr, J.A., "Fusion Bonded Epoxy (FBE)—A Foundation for Pipeline Corrosion Protection," Houston: NACE Press, 2003, p. 471.

16. Norsworthy, R., "Proven Protection," World Pipelines, October 2007, p. 49.

17. "Coating Used in Conjunction with Cathodic Protection," NACE Technical Committee Report, July 2000, p. 4.

18. Song, D., Song, F.M., Kirk, D.W., and Cormack, R.E., "Barrier Properties of Two Field Pipeline Coatings," Materials Performance, Vol. 44, No. 4, April 2005, p. 26.

19. Norsworthy, R., "Is Your Pipeline Coating 'Fail Safe'?," Pipeline and Gas Journal, Vol. 233, No. 10, Oct. ???, 2006, p. 62.

20. Roche, M., "External Corrosion of Pipelines; What Risk?," Paper E 93600-PP, SPE International.

The author

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com