OGJ Focus: Thermodynamics help determine underlying black powder processes

Based on an article published in the Saudi Aramco Journal of Technology, Fall 2009.

Thermodynamics can assist with understanding the underlying chemical processes of internal corrosion and black powder formation in dry gas pipelines. This is the case despite the presence of a wide range of corrosion products (iron oxides, iron carbonates, and elemental sulfur) sampled from the pipelines suggesting nonhomogeneous processes at play that are not thermodynamically controlled.

Intermittent ingress of oxygen from process upsets and cyclical wet-dry conditions resulting from process upsets and seasonal temperature changes are the main cause of these corrosion products, complicating the task of correlating the iron phases obtained at well-defined thermodynamic experimental conditions to the composition of the black powder formed in the pipelines at varying field conditions.

Background

The product of reactions between the steel of natural gas pipelines and components in processed natural gas concerns the gas industry. This corrosion product, commonly referred to as black powder, is a mix of iron oxides, sulfides, and carbonates, which causes erosion in valves and must be periodically removed by pigging the pipelines.1-4 Black powder samples collected from Saudi Aramco sales gas pipelines showed only the presence of iron oxides and carbonates (Table 1).4

Nonuniform conditions in the pipeline complicate understanding the mechanisms for black powder formation. Water content and dewpoints, H2S and CO2 concentrations, and the presence of oxygen all affect formation.

Water dewpoints were calculated under several operating parameters to determine which iron ion species would be predominant in the aqueous environment.

One of the main thrusts of this article's thermodynamic analysis was understanding, in sales gas with oxygen ingress, the predominance of iron oxide phases (magnetite-Fe3O4 and FeOOH) in the collected black powder, knowing from the literature5-7 to expect FeCO3 as the dominant species.

Iron oxide's predominance reflects the complexity of the corrosion problem caused by changing conditions in the gas phase (such as oxygen ingress or changes in the H2S, CO2, or H2O levels), the effect of kinetics on the reaction of pipeline steel with the solution, and the subsequent potential conversion of reaction products in a dry environment (i.e., the conversion of FeCO3 to Fe3O4).

The lack of definition regarding the specific location and time at which the black powder formed further complicates analysis. Analyzed samples instead represent the sum of black powder products formed at varying locations and times along the pipeline (i.e., water condensation might have occurred only at low points and for a few hours during the winter season, or oxygen ingress took place at low-pressure points, etc.).

These factors complicate correlating the results of thermodynamic analysis with field X-ray diffraction results. The wide range of potential conditions and kinetic limitations on the reactions means an attempt at quantitative analysis of thermodynamics as they apply to the formation of black powder could be misleading.

Although thermodynamics can be useful in predicting what can and cannot possibly form under dewing conditions, the fact that a wide range of products (iron oxides, carbonates, and elemental sulfur) is sampled from the pipelines shows this is not a homogeneous process controlled by thermodynamics. If the gas phase is relatively constant, thermodynamics would predict one stable phase for each of the nonmetallic components in the gas phase (i.e., S and C).

The presence of all the mentioned phases means there are regions of kinetic control in the pipeline. These uncertainties, however, mean the results should be used as a guide to better understand the corrosion mechanisms inside the pipeline.

System definition

Before thermodynamic analysis, it is important to define the terms of the calculations. Table 2 shows sales-gas compositions and measured dewpoints as obtained from two spot analyses each.4 Table 3 shows impurity levels and properties of sales gas.4 These levels set the conditions for the calculations outlined in the balance of the article.

The analysis presented here uses two main assumptions:

• CH4 and N2 were removed from the calculations and replaced with argon, so as not to affect reaction equilibrium.

• Sales gas would behave as an ideal gas. Dewpoint calculations, which match exactly when the ideal gas model is used but are not comparable when a real gas model is used, validate this assumption.

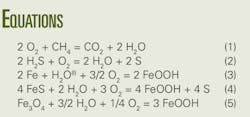

One problem with thermodynamic calculations is reactions that normally do not occur due to kinetic barriers cannot be prevented in the calculations without the removal of some species from the calculation. An important example of this is the reaction between oxygen and methane (Equation 1).

At pipeline temperatures methane is kinetically stable with respect to other gases. It is reasonable to assume the interaction of methane and nitrogen with other gases in the pipeline will be limited. It is not possible to conduct thermodynamic calculations with methane and nitrogen in the calculation because this kinetic barrier to reaction prevents thermodynamic calculations with methane and nitrogen, but the reaction still occurs in thermodynamic calculations, causing CH4 and N2 to be removed from the calculations and replaced by Ar so as not to affect reaction equilibrium. Since this article intends to show the potential for thermodynamic calculations as they relate to black powder formation, this assumption must be made to allow calculation.

The article will compare calculation results will be compared with experimental work currently under way on gas phase stability.

Another example of this gas phase kinetic barrier issue is CO-CO2 equilibrium. At low (less than 100º C.) temperatures, CO and CO2 can exist together at any ratio despite thermodynamics stating there would be a reaction between them creating elemental carbon. CO-CO2 gas blends in cylinders can remain at the same ratio virtually indefinitely.

Oxygen is the critical factor in the internal corrosion of sales-gas pipelines. Oxygen ingress in gas lines can cause corrosion in small concentrations and combustion in larger amounts. A 1988 survey of 44 natural gas transmission pipeline companies in North America showed gas-quality specifications allowing maximum O2 concentrations of 0.01-0.1 mol % with a typical value of 0.02 mol %.6 8 Oxygen content of about 0.01 mol % has little effect on steel corrosion in the presence of stagnant water inside sales gas transmission pipelines, while 0.1 mol % produces fairly high corrosion rates.6 8

This range points to the difficulty in making a quantitative analysis of the entire system. A general recommendation holds that operators of transmission pipelines should consider limiting maximum oxygen concentration to 10 ppmv (0.001 mol %).6 8 O2, due to air ingression in the gas, will not be at equilibrium with the other gases in the methane stream, due to the low kinetics of methane reacting with oxygen at operating temperatures.

Oxygen cannot exist (thermodynamically) in a reducing environment such as sales gas (Equation 1) because it would react with methane. If oxygen were at equilibrium with the methane, the partial pressure of O2 would be undetectable and CO2 and water concentrations would increase. H2S would remain relatively unaffected.

Conditions indicated by the equilibrium gas composition (i.e., the Eh and pH of the water or the equilibrium CO2 in the gas phase) will therefore not reflect the true kinetically controlled situation, requiring any calculations or diagrams based on the gas phase equilibrium be interpreted in light of expected kinetics (i.e., oxygen could remain in the system as a kinetically stable gas phase).

Specific reactions in black powder production problematic with regards to the application of thermodynamics follow. Kinetic barriers complicate accurate prediction of the equilibrium aqueous phase. But suppressing reactions in the calculations not occurring in the pipeline allows a reasonable estimate of the aqueous phase, increasing the usefulness of analyzing iron reaction products by EpH diagrams and aqueous-phase chemistry.

Dewpoint

Dewpoint calculations for a range of conditions demonstrated the validity of the calculations (Fig. 1). The operating temperature and pressure ranges measured 15-30º C. and 720-900 psig, respectively. Dewpoint calculations considered the balance of the sales gas as N2 and CH4 (CH4/N2 = 15.67), or Ar for purposes of the calculations.

Pressure has the largest effect on dewpoint. Calculations determined if dewpoint temperature changes as a function of contaminant concentrations and pipeline pressure. Fig. 1 compares the results obtained from a commercially available software package and the dewpoint calculated using the alpha moisture system dewpoint calculator. In all cases the results are within about 2º C. of each other. Impurities (H2S and CO2) had no effect on the dewpoint, while pipeline pressure and H2O affected dewpoint temperature.

Point calculations are thermodynamic calculations done to attempt to simulate the conditions in the precipitated water in the pipeline. They most effectively identify reasonable ranges of pH or redox for EpH diagrams or to help better understand reaction mechanisms. All calculations are based on 1 l. of gas and are in units of moles. The output from the thermodynamic model gives the equilibrium gas phase and the aqueous condensed phase.

Changing the values of CO2, H2S, and O2, allows a range of values for pH, Eh, and aqueous species concentrations. The concentration of aqueous species is important in setting the EpH diagrams to the correct values. Oxygen can be used in these calculations because Ar has replaced methane and nitrogen. This condition represents a transient condition where O2 has entered the pipeline, but does not react with methane due to kinetic constraints.

Changing gas conditions affect the solution's Eh and pH, low and high CO2 content. Maximum water concentration equaled 0.55 mg/l. CO2 will buffer the aqueous solution to a pH of about 4, typical of carbonate solutions. Adding H2S in a reducing environment has little effect on pH. Oxygen naturally drives up the Eh value, creating the potential for localized increases of Eh along the pipeline due to oxygen ingress.

The fact there are no pH conditions that would be above about 5 is consistent with work by Sridhar et al.5 using a range of conditions with CO2 at 10 psi and all conditions (except the one loaded with NaOH) showing a pH around 5. These results reinforce the difficulties of studying the problem in isolation from its surroundings, these relatively highly acidic pH conditions not being encountered in the pipeline.

The presence of iron in the system dramatically affects its chemistry. System pH normally lies between 5 and 6.5, due to the reaction of CO2 with iron. When iron is introduced into the calculation, FeCO3 precipitates, the pH increases to 5, and FeOH+ is found in the aqueous solution, much more in line with the actual field findings.

Formation of Fe3O4 is thermodynamically possible but depends on the availability of iron to the system (ratio of iron to gas phase), helping explain the range of compounds found in the pipeline.

Looking at the calculated reaction products as iron is introduced into the system allows study of the progression of product formation. In the presence of Fe (given an oxygen free system), FeS2 is the first iron compound to form (at pH ~4). FeCO3 forms next if the available sulfur is exhausted, increasing the pH to above 5. Relative rates of these reactions are not known and are affected by the relative concentrations of the gases.

Literature states the presence of both CO2 and H2S in condensed moisture produces a corrosion product that is a function of the partial pressure of both acid gases and temperature.6 Investigation suggests different CO2-H2S ratios, such as 200 and 500, representing the change from predominately FeCO3 to FeS6.

The preference for CO2 forming carbonate over H2S forming FeS (both reactants in aqueous form) is a kinetic phenomenon, and not based on thermodynamics. Thermodynamically, iron will preferentially react with S over CO2 at virtually any concentration of reactants. The fact that FeCO3 is found preferentially at high levels of CO2-H2S shows the kinetic reaction for S is less than for CO2, perhaps due to a passivating film occurring with sulfur or, as mentioned earlier, to exhaustion of S at the reaction site due to the slow dissolution of more H2S into the water (slow replenishment of S in the water).

As with CO2, calculations involving S as described are kinetically controlled. The prediction of the formation of SO42– from thermodynamics does not occur in the field. Reactions of oxygen and H2S appear to be kinetically slow, and the preferential reaction is as per Equation 2.

EPH diagrams

EpH diagrams can identify regions of pH and E (redox potential, or the oxidizing or reducing environment of the solution). Presentation of these diagrams often occurs in a series with varying conditions of activity of one of the species, because while EpH diagrams can be constructed for metals in water, when a nonmetallic element is introduced (in this case carbon or sulfur), another degree of uncertainty is added to the system. This uncertainty must be removed by setting the activity level or partial pressure of a compound containing that nonmetallic element.

Providing a series of diagrams with no reference to the actual system provides little value in understanding the mechanism of a reaction, making the point calculations performed in this work useful in helping determine reasonable concentrations of aqueous species for carbon and sulfur. Fig. 2 is the baseline EpH diagram for water.

FeOOH, the data entered into the commercial software package,8 did not appear. Conditions for its formation are not clear, but it can be assumed it forms in the presence of oxygen via Equation 3, or through conversion of reaction products via Equations 4 and 5.

This diagram is at 15º C., although temperature's effect is negligible over the range experienced by the pipelines. The region of interest lies between the two dashed lines, showing the region where water is stable. With only pure water and a basic pH Fe3O4 can form, as shown by this region in Fig. 2.

The progression moves from elemental Fe, to FeO (or Fe(OH)2 as shown), to Fe3O4, and finally to Fe2O3–, the most oxidized iron oxide. Removing the aqueous species from the diagram would show each phase field layered on top of each other as the electron volt increases (becomes more oxidizing).

CO2 influence

Adding CO2 changes the EpH diagram to that shown in Fig. 3 for a system with low CO2 in the gas phase (0.1 mol %). Adding C to the system requires there be a species selected with a fixed concentration. This can either be a gas (i.e., CO2) or an aqueous species (i.e., HCO3–).

This article selected HCO3– and took a representative value from the point calculations done in the last section. The carbonate phase, FeCO3, is covered by the aqueous FeOH+ and Fe2+ fields. This coverage only shows the ionic concentration in the system since the diagram is set to the typical 10–6 concentration for the sum of ionic species (if the total of all ionic species is at least 10–6, the predominant ionic species will be shown on the plot).

To see the solid phases, the ionic species can be suppressed in the output (Fig. 4). This plot, without aqueous species shown, clearly demonstrates FeCO3 as the phase of interest in the E and pH range, supporting the point calculations showing FeOH+ is present with CO2 and influences system pH.

EpH diagrams often display with the aqueous phase boundaries as dotted lines over the top of the solid phases. The concentration of aqueous species over a phase field shows the development rate of any corrosion, since corrosion will occur with greater intensity if the dissolved Fe ions build to a high concentration before equilibrium is reached.

Setting the concentration of aqueous species at 0.001 allows observation of the solid phase fields with the aqueous species. Fe3O4 forms at pH values greater than about 6.5, but the phase field overlaps the FeCO3 for a given pH, depending on the Eh of the system.

This overlap could explain why both FeCO3 and Fe3O4 are found in the black powder, since a pH of 6.5 or greater is found in laboratory tests at Saudi Aramco, and Eh could change depending on oxygen availability.

H2S influence

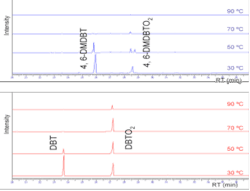

The effect of H2S on the pipeline depends on the atmosphere in the pipeline and kinetics. Oxygen does not react kinetically with H2S to create sulfates, meaning EpH diagrams can vary widely as to fields of stability depending on the situation in the system. Fig. 5 shows a simple EpH diagram using pH2S as the basis for the calculation yields.

Fe3O4 lies between FeS and FeS2. The Fe3O4 field is narrow (only visible as a thicker line), but at lower H2S concentrations it is more predominant, demonstrating a likelihood of FeS and FeS2 formation depending on redox potential.

Since oxygen ingress will affect redox potential and is a nonuniform event (sometimes minor, sometimes major), it is likely both FeS and FeS2 will be found in a range of concentrations with one another.

Examination of both CO2 and H2S demonstrates why a variety of solid material is found in black powder. Oxygen ingress can widely change system Eh and favor formation of one compound over another. The nature of the ingress—in terms of both concentration and location—leads to nonuniform residue, complicating the overall analysis of its formation.

Acknowledgments

The authors thank Saudi Aramco management for its support and permission to present the information contained in this article.

References

1. Sherik, A.M., Zaidi, S.R., Tuzan, E.V., and Perez, J., "Black Powder in Gas Transmission Systems," NACE Corrosion 2008, New Orleans, Mar. 16-20, 2008.

2. Baldwin, R.M., "Black Powder in the Gas Industry—Sources, Characteristics and Treatment," GMRC, Report No. TA97-4, May 1998.

3. Sherik, A.M., "Black Powder in Sales Gas Transmission Pipelines," Saudi Aramco Journal of Technology, Fall 2007, pp. 2-10.

4. Sherik, A.M., "Effects of Simulated Pipeline Processes on Black Powder Formation in Sales Gas Pipelines," Report No. DR-002/05-COR, April 2007.

5. Sridhar, N., Dunn, D.S., Anderko, A.M., Lencka, M.M., and Schutt, H.U., "Effects of Water and Gas Compositions on the Internal Corrosion of Gas Pipelines—Modeling and Experimental Studies," Corrosion, Vol. 57, No. 3, pp. 221-235, 2001.

6. Kermani, B., Martin, J., and Esaklul, K., "Materials Design Strategy: Effects of H2S/CO2 Corrosion on Materials Selection," NACE Corrosion 2006, San Diego, Calif., Mar. 12-16, 2006.

7. Lyle, F.F., "Carbon Dioxide/Hydrogen Sulfide Corrosion under Wet Low-Flow Gas Pipeline Conditions in the Presence of Bicarbonate, Chloride and Oxygen," PRCI Final Report PR-15-9313, 1997.

8. Majzlan, J., Grevel, K.D., and Navrotsky, A., "Thermodynamics of Fe Oxides: Part II. Enthalpies of Formation and Relative Stability of Goethite ((c)FeOOH), lepidocrocite (FeOOH), and Maghemite ((c)Fe2O3)," American Mineralogist, Vol. 88, pp. 855-859, 2003.

The authors

Abdelmounam M. Sherik ([email protected]) joined Saudi Aramco in 2004 and is currently working for the company's research and development center. Before joining Saudi Aramco, he held several research and engineering positions in Canada. Abdelmounam has over 20 years' professional experience in materials and corrosion. He received his BS in materials science and engineering from Tripoli University, Libya, (1986) and his MS and PhD degrees in materials and metallurgical engineering from Queen's University, Kingston, Ont. He is active in the National Association of Corrosion Engineers, chairing the 2010 Corrosion in Gas Treating symposium and Black Powder in Gas Pipelines technology exchange group.

Boyd R. Davis has worked as a consultant since 1997 in computational thermochemistry and process development and is president of Kingston Process Metallurgy Inc. Boyd received his BS in engineering chemistry (1988) and MS and PhD degrees in metallurgical engineering (1994) from Queen's University, Kingston, Ont. Boyd volunteers his time to supervise graduate and undergraduate student theses and teach a first-year design course. Boyd is programming chair of the Extractive and Processing division of the Metals, Minerals, and Materials Society and is active with the Metallurgical Society of CIM where he was awarded the past presidents' memorial medal in 2001 for service.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com