New method streamlines thixotropic crude calculations

A new method of describing thixotropy in waxy crude oil transported through pipelines is both accurate and more convenient than previous methods. Thixotropy is an important rheological behavior of waxy crude oil. It reflects the weakening of the waxy structure's strength under shear action.

Theoretical derivation uses the Moore structure model, yielding both a proposed equation for describing the thixotropy of waxy crude oil and a suggested method for its application.

Regression results of eight groups of thixotropic experiment data from two waxy crude pipelines had a maximum correlation coefficient of 0.9907 and a minimum coefficient of 0.9532.

Background

Wax crystals precipitate from waxy crude oil when the temperature drops below the wax appearance temperature (WAT). As the temperature continues to decrease, more wax crystals separate out and interlock to form a wax crystal network, trapping liquid oil within its structure and leading to gelation of the crude oil.

At the same time, crude oil viscosity increases rapidly and exhibits complex rheological behaviors, such as irreversible thixotropy, viscoelasticity, and yield stress.1 The thixotropic behavior of waxy crude oil reflects the weakening of the waxy structure's strength under shear action. At a constant shear rate, the shear stress decreases with increasing shear time before attaining dynamic equilibrium.

Oil temperatures in a heated oil pipeline in shutdown decrease due to low ambient soil temperature. Part of the oil in the pipeline will exhibit thixotropy. The pipeline cannot be restarted successfully if restart pressure is not high enough to destroy waxy structures in the oil. Thixotropy of the crude oil influences pressure, flow rate, and restart time. Accurately predicting restart pressure of a waxy crude oil pipeline therefore requires a quantitative description of thixotropy.

Many flocculated materials demonstrate thixotropic behavior.2-3 Most existing thixotropic models adhere to the structure parameter model. The Houska model is widely used to describe thixotropy of waxy crude oil but cannot express the irreversibility of the waxy structure.

Other thixotropic models address the irreversibility of the structure, decreasing rates of yield stress, and the consistency coefficient.4-6 These models' results are more accurate than the Houska model, but their complexity makes it extremely difficult to determine the values of their parameters, restricting their usability.

Other models using either direct data regression or a mechanical approach don't address shear rate, an important variable.7-11 They cannot accurately address crude thixotropy in an oil pipeline and therefore should not be considered a thixotropic model in the strict sense. This article uses the Moore model to propose a method for describing thixotropy conveniently and accurately by theoretical and experimental analysis.

Mathematical model

Various proposed thixotropic models describe the thixotropic behavior of non-Newtonian fluids, the most representative being the structural Moore model.7

Equation 1 (in the accompanying equation box) is the state equation of the Moore model. Equation 2 is the Moore model's rate equation.

Equation 3 represents the boundary condition of the Moore model. Equation 4 presents the changed form of Equation 2.

Substituting Equation 4 into Equation 1 yields Equation 5.

Shear time tending to infinity yields the equilibrium state of the material. The structure parameter will not change and g equals 0. Equation 6 shows the equilibrium structure parameter according to Equation 4.

Combing Equation 1 and Equation 6 yields the equilibrium shear stress (Equation 7). Equation 2 can be changed into Equation 8.

Integrating Equation 8 and referring to boundary condition (Equation 3) yields Equation 9. Equation 10 shows the integration result of Equation 9.

Equation 6 says Equation 10 can be changed into Equation 11. Substituting Equation 11 into Equation 1 yields Equation 12.

Equation 7 allows Equation 12 to be written as Equation 13. Equation 13 shows shear stress decreasing exponentially with increasing shear time.

Discussion, modification

Equation 3 and Equation 7, respectively, denote relations between the maximum shear stress, τ0, equilibrium shear stress, τe, and applied shear rate. They do not, however, fit the experimental data well. Regressing the thixotropic experimental data allows derivation of more accurate relation equations.

Using Equation 13 to describe the thixotropic behavior of waxy crude oil failed to resolve the error between calculated results and tested data. Adding a modifying index, m, to the shear time in Equation 13 strengthens the effect of shear time on thixotropy.

Field analysis

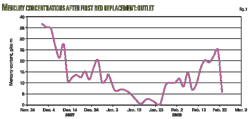

Field pipeline specimens consisted of virgin Zhongyuan crude oil, and Zhongyuan crude oil with a pour-point depressant added. Heated temperatures measured 50° C. and 65° C., respectively. Their gel points were 32° C. and 28° C., respectively. A viscometer using shear rates of 1 s–1, 2 s–1, 4 s–1, and 8 s–1 measured four thixotropic curves relating shear stress to shear time.

Thixotropic experiment data analysis showed maximum shear stress and equilibrium shear stress increasing as shear rate increased at the same temperature. These can be expressed with power function of the shear rate, τ0, = pΥ· η and , τe = cΥ· d where p, q, c and d are constants.

Regression results for the thixotropic experiment data showed the value of m as being related to the type of crude oil. The m values of virgin Zhongyuan crude oil and PPD-treated Zhongyuan crude oil measured 0.2000 and 0.2754, respectively.

The accompanying table lists regression results of the thixotropic experiment data according to analysis of the change in maximum shear stress, τ0, and equilibrium shear stress, τe , with the shear rate, Ý . Average correlation coefficients measure 0.9744 and 0.9728 for virgin Zhongyuan crude oil and PPD-treated Zhongyuan crude oil, respectively. The maximum correlation coefficient measures 0.9907, the minimum correlation coefficient 0.9532. The average correlation coefficient is 0.9732.

Fig. 1 shows the measured and calculated thixotropic curves of virgin Zhongyuan crude oil at 31° C. and PPD treated Zhongyuan crude oil at 21° C.

Acknowledgment

The authors acknowledge the financial support from National High Technology Research and Development of China (Grant No. 2006AA09Z357)

References

1. Li, C.X., "Rheology of Crude Oil," Monograph, Press of China Petroleum University, pp. 21-32, (in Chinese), January 2007.

2. Barnes, H.A., "Thixotropy—A Review," Journal of Non-Newtonian Fluid Mechanics, No. 70, pp. 1-33, May 1997.

3. Mujumd, A.R.A., "Transient Phenomena in Thixotropic Systems," Journal of Non-Newtonian Fluid Mechanics, No. 102, pp. 157-178, July 2002.

4. Zhao, X.D., "Nonsteady Hydrodynamical and Thermodynamical Calculation Method of Restart Process of PPD Beneficiated Crude Oil Pipeline," Dissertation, University of Petroleum, pp. 35-36 (in Chinese), June 1999.

5. Hou, L., and Zhang, J.J., "Study on Thixotropy of Waxy Crude Based on Viscoelasticity Analysis," Journal of Petroleum University, Vol. 29, No. 4, pp. 84-86 (in Chinese), August 2005.

6. Chen, H.J., Zhang, F., and Zhang J.J., "Calculation of Restart Pressure of Thixotropical Crude Oil," Oil and Gas Storage and Transportation, Vol. 23, No. 6, pp. 20-22 (in Chinese), December 2004.

7. Ai, M.Y. "A Method to Confirm Thixotropy of Non-Newton Fluid," Proceeding, "Advance in Rheology," China Chemical Industry Press, pp. 151-157 (in Chinese), October 1996.

8. Dong, P.S., Zhang, G.Z., and Hu, X.J., "A New Model Describing Thixotropy of Waxy Crude Oil," Oil and Gas Storage and Transportation, Vol. 24, No. 2, pp. 29-32 (in Chinese), April 2005.

9. Zhao Z.C. and Wang D., "Thixotropy of Waxy Crude Oil at Solidifying Point," Journal of Dalian University of Technology, Vol. 46, No. 1, pp. 20-24 (in Chinese), February 2006.

10. Labanda, J., Marco, P., and Llorens, J., "Rheological Model to Predict the Thixotropic Behavior of Colloidal Dispersions," Colloids and Surfaces A: Physicochem, Engineering Aspects, No. 249, pp. 123-126, July 2004.

11. Alexandrou, A.N. and Georgiou, G., "On the Early Breakdown of Semisolid Suspensions," Journal of Non-Newtonian Fluid Mechanics, No. 142, pp. 199-206, May 2007.

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com