Separations technology improves amine system's overall reliability

Based on a presentation to Oil Sands and Heavy Oil Technologies Conference & Exhibition, July 14-16, 2009, Calgary.

Expansion and modifications at Marsulex Montreal Inc.'s sulfur-handling plant in Montreal have increased the plant's overall reliability through improved amine quality, improved the plant's operating costs as a result of a longer interval between cleaning, and yielded better hydrocarbon recovery.

Amine systems in many refineries today are struggling to handle increased acid-gas loads resulting from low-sulfur gasoline and diesel production. Initiatives to increase amine and sulfur plants' reliability must ensure filtration and separation technology removes particulate and liquid contaminants in the amine circuits.

Marsulex Montreal's sulfur-handling plant sits near two refineries in Montreal. Hydrogen sulfide-rich amine arrives by pipeline at the Marsulex plant, which regenerates the amine and returns it to the refineries.

As part of a 50% expansion project completed in 2006, Marsulex installed the most current separations technology to reach the maximum design capacity by eliminating particulate and hydrocarbon ingression and contamination that were previously fouling plant equipment, reducing the amine solution's regeneration efficiency and thereby reducing reliability.

Deployment of rich-side filtration and high-performance liquid/liquid coalescers mitigated expensive equipment replacement and saved money.

Amine contamination

Expansions to existing refineries, along with the shift in crude diets to heavier and more sour "opportunity crudes," have put refinery amine circuits and sulfur plants under more stress than ever before. With these increased sulfur loads, corrosion products, liquid hydrocarbons, and organic acids are making their way into the amine units.

That amine cleanliness plays a crucial role in overall amine and sulfur-plant performance and reliability is documented.1 2 Contaminants must be reduced or eliminated to ensure reliable plant operation and environmental compliance.

Particulate matter found in amine solutions are, generally speaking, corrosion by-products. Solid contaminants are known to stabilize foams when foaming occurs.

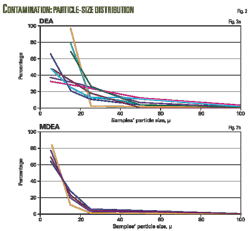

A review of field test data from Pall's databases going back many years has shown consistently that particle-size distribution of suspended solids is generally finer than 20 μm, with the majority of particles smaller than 10 μm. This observation has been generally consistent even when total suspended solids have varied from site to site.

With mixed results, refiners (and gas plants) have used different filtration and separation methods to combat the most common contaminants found in amine circuits. What is generally accepted as good practice is that total suspended solids in an amine circuit should be kept to less than 1 ppm by weight2 3 and liquid hydrocarbons and organic acids must be reduced to levels as close to zero as possible.

Following is a summary of amine-circuit filtration data compiled from Pall's Scientific and Laboratory Services field tests. These data are a composite of results obtained in 10 countries from 17 refineries owned by 10 oil companies.

Fig. 1 shows diethanolamine as the most sampled amine and exhibiting the widest band of contamination, from a few ppmw to nearly 120 ppmw. What is telling is that in nearly all cases, the total suspended solid levels exceed recommended best practice of no more than 1 ppmw suspended solids, as advised in the expert literature.3

Fig. 2, showing particle-size distribution for several samplings of DEA and methyldiethanolamine, shows that most particles are smaller than 20 μm.

In complex refineries, liquid hydrocarbons can come from amine/LPG contactors or as condensibles in refinery fuel gas. Typically, the cause is poor liquid/liquid contactor outlet disengagement between LPG and amine or inadequate inlet separation of free liquids in refinery fuel gas entering vapor/liquid contactors.

In complex refineries, which have multiple contactors and in which it is difficult to pinpoint culprit streams, the best option is to deploy central filtration and separation to eliminate free liquid hydrocarbons from the amine.

High-performance liquid/liquid coalescers can break the stable, rich-amine/hydrocarbon emulsion that can damage the amine unit and sulfur-plant operations, which can in turn elevate overall refinery SO2 emissions.

Within the amine circuit itself, the impact would be felt in the rich/lean heat exchangers, regenerator, reboiler tubes, and tower trays and packing, if left untreated. The consequences can range from heat-exchanger fouling, hydrocarbon entering the sour-water reflux discharge, increased corrosion, high amine losses due to foaming in contactors, formation of amine degradation products, or generation of heat-stable salts.

The efficiency of the sulfur-recovery unit and the life of the converter catalyst are degraded by carried-over hydrocarbons in the acid gas. In a serious hydrocarbon carryover, the consequences can be much more severe. These include soot deposition in the converters, runaway hydrocarbon combustion in the Claus unit, and high SO2 emissions that result in regulatory penalties and possibly expensive capacity reductions.

In the worst cases, there might be the need to switch to sweeter crude slates as a mitigating strategy to reduce the sulfur load on the amine and Claus plants to curb emissions.

Hydrocarbon separation

In the rich-amine side of the process, a rich-side liquid/liquid coalescer, as proposed here, will perform a dual role:

• 100% rich-side filtration to remove solid particles, mainly FeS corrosion products.

• Elimination of free-hydrocarbons in the downstream process to near solubility level.

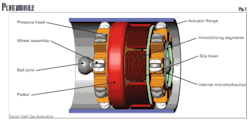

As an example, Pall's PhaseSep coalescer is a multiple-stage system starting with prefiltration (Fig. 3) that will remove particulate matter, provide protection, and pre-condition the feed to the coalescer. The coalescence stage that follows breaks the emulsion and allows the capture of dispersed hydrocarbon phase droplets, resulting in the separation of the two dissimilar streams.

Phase separation liquid/liquid coalescers operate over a range of conditions, including where:

• The emulsion has an interfacial tension as low or lower than 5 dyne/cm. (PhaseSep coalescers have been applied in applications with an IFT as low as 0.5 dyne/cm.)

• The dispersed phase fluid is hydrocarbon, and continuous phase is aqueous (amine).

There are three essential steps to achieving an efficient liquid/liquid separation:

Stage 1: Prefiltration. A rich-side full-flow prefilter is essential to protect and provide maximum operating life to the liquid/liquid coalescer. At the same time, and more importantly, 100% rich-side filtration prevents passage of suspended solids that may deposit in downstream equipment such as rich/lean heat exchangers, column packing or trays, and reboilers.

Stage 2: Coalescence. The two-phase liquid emulsion enters the coalescing element and flows inside-to-outside. This is where small, suspended droplets of the dissimilar fluid coalesce as the emulsion moves through a proprietary, specially formulated coalescer medium.

Stage 3: Separation. The coalesced dispersed phase separates in the settling zone of the coalescer housing. Due to the density difference on the two phases, these separated liquids exit through separate drain and outlet connections at the back end of the liquid/liquid coalescer housing.

Marsulex experience

Up until 2004, the Marsulex amine unit was relatively reliable. Although it never had to be shut down for unplanned maintenance, its efficiency and maintenance costs were affected by amine contamination. The residence time of the flash drum was 22 min on average, with a design residence time of 19 min. This was sufficient to handle most hydrocarbon carryover conditions.

A simple particle filter assembly was installed on a 15-20% cleanup loop on the lean-amine side. It offered partial filtration of the lean amine before the refineries' contactors but no protection for the Marsulex amine unit and sulfur plant.

Following the planned 2006 expansion project, the maximum amine recirculation flow capacity would increase and therefore reduce the residence time in the flash drum. The operational residence time would be reduced to 13 min (at operating liquid level) or 9 min (at 50% liquid level). This was considered insufficient to separate liquid hydrocarbon from the amine adequately, raising concerns about the reliability of the plant under the new operating regime.

In preparation, Marsulex invited Pall to perform an on site demonstration of rich-side full-flow prefiltration and liquid/liquid coalescence. Testing performed during the fall of 2004 helped better define the contamination at the outlet of the existing flash drum. The site trials also validated the effectiveness of rich-side filtration and confirmed the efficiency of the liquid/liquid coalescer technology at separating hydrocarbons from rich-amine.

During on site testing, the following were observed:

1. Even with adequate flash drum residence time, hydrocarbon/amine emulsion remained stable, as shown by rich-amine samples remaining hazy for longer than 3 weeks (Fig. 4, Sample B). Pall's high-efficiency PhaseSep liquid/liquid coalescer was capable of breaking and separating this emulsion in a single pass.

2. Rich-amine particulate concentrations vary substantially depending on the refinery's operating conditions at a given point in time. Using a 10-μm absolute-rated filter (Beta10 μm = 5,000) helped reduce suspended solids to concentrations near or less than 1 ppmw.

3. Hydrocarbon (C5 to C60) levels found upstream of the liquid/liquid coalescer pilot unit ranged 86-193 ppmw and included low levels of benzene, toluene, ethylbenzene, and xylene. Pall's PhaseSep liquid/liquid coalescer reduced overall hydrocarbon to near solubility in amine, based on a total extractable hydrocarbon analysis, using a Horuba Oil Content Analyzer (extractive infrared analyzer).

4. The average solids loading at the outlet of the flash tank (inlet of the rich-side filter) was 5 ppmw, with the lowest data point being 2 ppmw and the highest being 10 ppmw. The average solids loading at the outlet of the filter was <1 ppmw, having a range of values from nondetectable to 2 ppmw.

Based on the field trial results, Marsulex decided to install a full-flow, duplex filtration package followed by a full-flow high-performance PhaseSep liquid/liquid coalescer unit (Figs. 5-7).

Operating data

The rich-side filter and coalescer units were installed early in 2006 and started up in June of that year. Before start-up of the equipment, the rich-amine was hazy and had a green-gray color at the outlet of the flash tank.

Since the unit has been in operation, amine samples at the outlet of the filtration and coalescing system are clear and bright, exhibiting the characteristic light straw color of a clean amine, as seen in Fig. 4, Sample C.

It was observed that, both in amine analysis and overall process stability, amine quality has improved. The most significant improvement has been in the consistently low concentration of suspended solids. Before the rich-side filtration coming on-line, total suspended solids in the circuit would reach 30 ppmw. Today, solids are found to be 1 ppmw on average, downstream of the rich-side filter.

With the liquid/liquid coalescer in place, the continuous low-level hydrocarbon ingression is being removed everyday. More critically, when episodic hydrocarbon spikes occur, the liquid/liquid coalescer responds immediately by separating the liquid hydrocarbon slugs, preventing circuit contamination, and maintaining circuit stability.

Upset

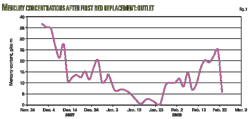

Since start-up of the rich-side filters and liquid/liquid coalescers, there has only been one major hydrocarbon carryover to the sulfur-recovery unit and one major foaming incident at the refinery contactors.

On the first occasion, an upset occurred at the time when the filters and liquid/liquid coalescer were bypassed for filter element changeout. This was during a period of very high solids, and filter life was short.

The event should have been a warning for the larger hydrocarbon spike that followed. Following the 5-hr shutdown to replace the filter elements, it took 3 days and eight filter replacements to clean the particles and hydrocarbon out of the amine loop and restore stability.

The second incident was most likely due to hydrocarbon contamination of the amine during a coalescer shutdown. Given the system is a closed loop, however, it cleaned up and recovered once the coalescer was returned to service.

Employing the best practice of rich-side filtration and hydrocarbon coalescence proved the system can, and will, recover quickly. The alternative is unchecked contamination of the circuit that conventional separations techniques are inadequate at addressing (Figs. 8 and 9).

Since December 2007, the system has been operating without requiring coalescer shutdown. In February 2009, there was another major hydrocarbon carryover from one of the refineries. This time the coalescer extracted 840 gal (20 bbl) of hydrocarbon liquid over 2 days. High solids did not accompany this event, and the filter did not plug prematurely. With the separation train remaining online, there was no impact on the amine loop and the situation returned to normal as soon as the hydrocarbon contamination source was located and the cause for the discharge addressed.

To date, the amine heat exchanger train, reboilers, and regenerator tower have been performing without any need for shutdown. Unfortunately, we cannot compare performance before and after installation of the rich-side equipment because the entire circuit was significantly modified during the 2006 project. Marsulex can confirm, however, the general fouling tendency is greatly reduced compared with before the filtration unit start-up.

Today, Marsulex is projecting a 3-year or better turnaround schedule for the entire heat-exchanger train. The reboiler cleaning schedule will be based on the trends revealed from Marsulex's monitoring program.

Process benefits

The most important benefit that the system provides is an increase in overall reliability of the amine system and sulfur plant. While the system's ability to allow for quick recovery after a particulate and-or hydrocarbon contamination event—which keeps the system performing at capacity—is the primary benefit, the operating costs are also greatly improved due to longer time between cleaning and better hydrocarbon recovery.

The lean/rich exchangers cleaning frequency has returned to a preventative maintenance schedule: five in 3 years vs. a required eight in 3 years due to significant fouling of the heat exchanger train.

Over time, Marsulex will reassess the schedule based on inspections. The frequency reduction is expected to save a minimum of $100,000 on maintenance costs. This is in addition to the energy savings realized with reduced steam consumption in the regenerator reboiler (not calculated here).

The liquid/liquid coalescer allowed greater liquid hydrocarbon recovery when compared to the flash drum alone. On average, the amount of liquid hydrocarbon recovered increased by 25%. For example, in 2008, this resulted in recovery of an additional 4,830 gal (115 bbl) of liquid hydrocarbon.

This offsets fuel costs because the recovered oil is now being fed to a boiler. Most importantly, removal of this volume of hydrocarbon ensures amine circuit stability, and protection of the downstream sulfur plant.

References

1. Spooner, Ben, Sheilan, Mike, and van Hoorn, Egebert, "Iron Sulphides—Friend or Foe," Laurance Reid Gas Conditioning Conference, Feb. 25-28, 2007, Norman, Okla.

2. Brown Jr., Robert L., and Hashemi, Reza, "Predicting Contamination Levels of Upset Conditions in Amine Sweetening Systems," AIChE Spring Meeting, Mar. 30, 1993, Houston.

3. Verma, Narendra, and Verma, Anil, "Amine System Problems Arising from Heat Stable Salts and Solutions to Improve Performance," Fuel Processing Technology, Vol. 90 (April 2009), No. 4, pp. 483-489.

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com