Natural gas, one of Earth’s cleanest, most abundant resources, accounts for 22% of total US energy use but only 2.2% of the energy used in the US for transportation, although the technology for natural gas vehicles (NGVs) has been available since World War II.

“It took 60 years to grow the worldwide NGV population to only 1.7 million vehicles by 2001,” said John Lyon, president and CEO of FuelMaker Corp. and former president of the International Association for Natural Gas Vehicles, at the group’s June meeting in Rio de Janeiro.

Since then, he said, “Something happened to drive the NGV population to over 7 million vehicles, an astounding annual growth rate of 26%.” NGVs have increased rapidly in Europe and South America primarily because of environmental concerns and rising prices for crude, gasoline, and diesel.

At a conservative annual growth of 18%, Lyon said, “There will be 65 million NGVs by 2020, representing 9% of the world’s vehicle population and reducing oil demand by 7 million b/d.” He added, “Many gas producing and gas delivery companies are now recognizing that by 2020 NGVs will represent a 400 billion cu m/year market (16% of today’s total world gas demand).”

The US Department of Energy expects alternative-fueled vehicles to account for 10% of the US automobile market by 2020 when more than 286 million vehicles will be on US roads.

To reach that goal, the US government is offering incentives, including fuel excise tax credits of 50¢/gal for equivalent compressed natural gas (CNG) and liquefied natural gas (LNG) fuels. It also offers tax credits for 30% of infrastructure costs; up to $1,000 for home refueling appliance or as much as $30,000 for a commercial project.

In an October study, DOE found, “Alternative fuel prices relative to conventional fuels vary, with some (biodiesel, propane) higher and some (Ethylene 85 and CNG) lower. CNG is about $1.03 less than gasoline on an energy-equivalent basis, while E85 is about 22¢/gal less than gasoline.” Although the average US retail price of propane was 34¢/gal higher than the average price for gasoline, propane prices were “generally favorable” in the West, DOE said.

It reported, “Prices for the alternative fuels in terms of cost per gallon equivalent are generally higher than their cost per gallon because of their lower energy content per gallon. It has been seen, however, that consumer interest in alternative fuels increases as the price differential per gallon increases, even if that differential does not directly translate to savings on an energy-equivalent basis.” Federal officials also noted extreme weather anywhere in the US can increase natural gas prices.

NGVs cost more due to the need for special fuel tanks and engine modifications. Heavy duty NGVs, such as trucks and buses, typically use LNG rather than CNG for their bigger engines. The most established US niche market for gas as a transportation fuel is gas-powered transit bus systems. In 2006, 15% of US transit vehicles were powered by natural gas, replacing 109 million gal of diesel.

Propane

Some 20 years ago when the Department of Transportation began mandating service signs for alternative fuel outlets along interstate highways, the first such sign erected in Houston and other sections of the US was for propane.

Propane or LPG has been an alternative fuel for spark ignition engines since the 1940s. It is the third most popular vehicle fuel in the US after gasoline and diesel, and its distribution system is widespread compared with other gas alternatives. The National Propane Gas Association (NPGA) counts 13,500 retail propane outlets, but DOE lists some 2,500 propane fueling stations for automobiles, the largest system of any alternative fuel in the US but still far fewer than gasoline or diesel stations.

DOE estimates that there are more than 270,000 on-road propane vehicles in the US and more than 10 million worldwide. Exact counts are difficult, however, because the designation of propane-fueled vehicles may include off-road and industrial equipment such as forklifts, while some propane fueling stations may be small outlets fueling barbecue grills. Still, many converted propane vehicles have provisions for topping off from “barbecue bottles.”

Although the capital structure for production, storage, and bulk distribution of propane already exists, additional investment will be required to accommodate higher throughput for automotive use. Existing service station facilities designed for gasoline and diesel can be modified to dispense propane. The World LP Gas Association said installation costs for equipment to dispense propane is two-thirds less than that for CNG.

Propane can deliver up to 90% of gasoline’s miles per gallon with less pollution. Its energy density and fuel efficiency relative to gasoline surpasses those of all other alternative fuels—70% for ethanol, 54% for methanol, and 21% for CNG. Moreover, many governments impose less tax on propane than on gasoline and diesel, so it is usually more cost effective, proponents claim.

The fuel is a gas at normal temperatures and pressures, but in a vehicle fuel tank, it is pressurized to 300 psi—“about twice the pressure as an inflated truck tire,” said DOE officials—making it a liquid with an energy density 270 times greater than its gaseous form. It returns to a gas before it is burned in an internal combustion engine, so the engine runs more efficiently in low-speed, light-throttle conditions. Propane’s high octane rating (104-112 compared with 87-92 for gasoline) and low carbon and oil contamination characteristics have resulted in documented engine life of up to three times that of gasoline or diesel engines, NPGA said.

The Battelle Memorial Institute reported that propane is the most economical alternative fuel per mile for fleets when operating, ownership, and infrastructure costs are all taken into consideration. NPGA said operating costs for propane fleets are typically 5-30% less than those of gasoline fleets.

The Propane Education & Research Council (PERC) is expanding its commercialization strategy to help manufacturers bring to market new propane-fueled vehicles and equipment and to engage the industry in building markets for new end-use technology. Late last year, PERC approved a multiyear $4.7 million project with Roush Industries, Livonia, Mich., to produce and certify a series of propane-fueled Ford trucks and conversion kits, dependent upon Roush’s obtaining emissions certification from the California Air Resources Board.

CNG

CNG vehicles can use the fuel as either a liquid or a gas, but most use the gaseous form compressed at 3,000-3,600 psi to less than 1% of its volume at standard atmospheric pressure. That compares with a household gas pipe pressure of 1-2 psi. Because it is not liquefied, CNG’s volumetric energy density is estimated at 42% of LNG and 25% of diesel.

According to DOE, the equivalent energy of 1 gal of gasoline is 118 scf of CNG or 1.6 gal of LNG. The energy equivalent of 1 gal of diesel is 130 scf of CNG or 1.7 gal of LNG.

In October the DOE found CNG was priced lower than gasoline in all surveyed regions, with the largest difference—$1.88/gal of gas equivalent—in the Rocky Mountain region. On average, CNG cost $1.03 less than gasoline on a per gallon of gas equivalent basis. The variability of CNG prices was higher than the variability of gasoline prices, based on a standard deviation analysis.

Because it does not require super cooling and cryogenic tanks, CNG has lower production and storage costs than LNG. It does require high pressure and a larger volume of storage than the same mass of gasoline or diesel, but proponents say it is safer than other fuels in the event of a spill, as natural gas disperses quickly when released.

CNG is used primarily in converted gasoline engines, but it also can be used in modified diesel cycle engines in light-duty passenger vehicles and pickup trucks, medium-duty delivery trucks, and mass transit and school buses. A few railroads have converted train engines to CNG, including the Napa Valley wine train.

CNG refueling stations are less readily available outside California, so corporate fleets build their own fueling systems. One study by the Washington Metro Area Transit Authority found operating costs increased by 3-8¢/mile with CNG. A separate UPS study found operating costs increased 19% in one CNG fleet, but were down 2% compared with diesel in another fleet.

DOE reported 120,500 NGVs on US roads in 2004, including 98,300 in private use, mostly through corporate fleets; 10,700 in state fleets, and 11,400 in federal fleets. A 2007 study found 15% of the stations pumped 65% of the CNG sold; Another 75% of the stations were responsible for 34% of the sales, while 10% of the stations move just 1% of the market. Many of the “dormant or grossly underutilized” stations have little chance of increasing throughput. Many are in need of large investments to become viable, and additional attrition of some stations is likely.

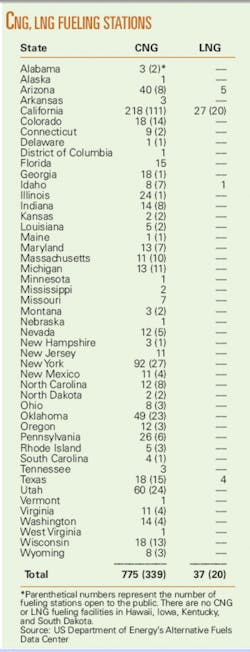

Some CNG outlets listed by the Alternative Fuels Data Center as open to the public are on military bases or at regional airports where the general public may not have unrestricted access. There are no CNG or LNG fueling facilities in Hawaii, Iowa, Kentucky, and South Dakota. However, Iowa, the major US producer of corn, has 107 E85 fueling outlets (see table).

Of the total CNG automobiles around the globe, 48% are in South America. Argentina and Brazil have the largest fleets of CNG vehicles. NGVs commonly serve as taxicabs in major cities.

Argentina has 1.69 million NGVs—15% of the world’s total—and 1,767 CNG stations. Brazil has 1.56 million retrofitted vehicles, 5% of the world’s fleet of CNG light vehicles, with 1,585 fueling stations. In addition, a network of CNG stations is being developed along major highways of South America’s Southern Cone (including Chile and Bolivia) to encourage CNG use for long-haul transportation.

In Europe, Italy has the most CNG vehicles and is in fourth place worldwide. CNG also fuels automobiles in Iran, Pakistan, Bangladesh, and India.

US federal tax credits are available for buying new CNG vehicles, and there are tax credits of up to 50% of the costs of auto conversions and installation of CNG home filling stations. Fueling CNG vehicles from fuel lines in home garages is on the rise in the US, particularly in California and New York, and tax credits are available for installing the necessary appliance. However, overnight-fueling from residential gas lines is forbidden in some countries.

Because of state government subsidies, Utah—with 60 CNG fueling stations, including 24 open to the public—has the third largest US network of CNG fueling stations behind California (218, with 111 public) and New York (92, of which 27 have public access). However, Proposition 10, a $5 billion bond measure that would have provided rebates to state residents for purchases of CNG vehicles, was defeated by California voters, 59.8% to 40.2%, in 2008.

LNG

Because it is less polluting and the cost relatively low compared with diesel, LNG is on the rise in the US transportation fuels market. It is produced in a liquefaction process when natural gas is cooled to –259° F. Due to the necessary special equipment, an average NGL station would cost $1 million.

Because of its higher storage density, proponents claim LNG is a more viable alternative to diesel fuel than CNG. Moreover, they say LNG in heavy-duty natural gas engines achieves significantly lower NOx and particulate emission levels than diesel.

Because of LNG’s increased driving range, it is used in heavy-duty vehicles, typically vehicles with gross weights of 33,000-80,000 lb.

In some regards, industry experts said, LNG is safer than propane or gasoline because it is flammable only within a narrow range of fuel:air ratio. It is less subject to accidental fire if vapors come into contact with a spark or flame, and, in the event of an accidental fire, methane tends to burn along a flame front rather than explode. Being lighter than air, methane generally rises and dissipates instead of accumulating at dangerous concentrations the way gasoline and propane vapors do.

Still, fires and explosions can occur under certain conditions. Furthermore, LNG is stored as a pressurized liquid at very low temperatures below –200° F., so handling and use are subject to the general risks associated with any cryogenic fuel, including the risk of skin and eye burns on contact.

Clean Energy Fuels Corp., formerly Pickens Fuel Corp. founded by entrepreneur T. Boone Pickens, is the largest provider of CNG and LNG, fueling thousands of vehicles. In late November, it started up the largest LNG production plant in the Southwest and the first large-scale plant in California to produce up to 160,000 gal/day of LNG for Clean Energy’s new LNG truck fueling station in Carson, Calif. The station provides fuel for trucks serving the ports of Los Angeles and Long Beach.

DOE said the two ports are the largest source of air pollution in the greater Los Angeles area. The ports created a Clean Truck Program as part of their 2006 Clean Air Action Plan to alleviate the pollution. That program, which took effect Oct. 1, 2008, immediately banned from the ports 2,000 trucks built before 1989, the first year for pollution controls on diesel-fueled trucks. By 2012, the program will bar any trucks not complying with the cleanest 2007 emission standards. “Right now, that adds up to another 14,000 trucks,” port officials said.

The Clean Energy LNG plant in Boron, Calif., 125 miles northeast of Los Angeles, is designed to expand production to as much as 240,000 gpd of LNG as demand increases. The company has begun construction of a second regional LNG truck fueling station, which is scheduled for completion in March.

GTL

Gas-to-liquids (GTL) is the newest of the gas fuel alternatives. From natural gas the technology produces clean-burning liquids such as diesel fuel, LPG, and naphtha that meet the most stringent environmental requirements.

That market is rapidly developing. A little more than a year ago, an Airbus A380 became the first commercial airliner to fly with GTL-based fuel. In 2008, an Audi powered by GTL diesel won the 24-hr Le Mans race in France for the third consecutive year.

Like LNG, GTL provides a means of developing and commercializing isolated gas fields, creating an international market for gas similar to that for oil. Natural gas has a far wider market in liquid form because it is easier to transport. With GTL processes, refineries can convert some gaseous waste products into valuable fuel oil virtually free of sulfur, nitrogen, and aromatics.

Dutch Shell PLC, a pioneer in GTL, said the fuel is essential to production of a more advanced diesel grade specifically designed to help diesel engines deliver more power for a longer period. The company has operated a medium-scale GTL plant at Bintulu, Malaysia, since 1993, with a current capacity of 14,700 b/d. Diesel containing Shell GTL is marketed in nine European countries plus Thailand and the UK.

Shell is in the process of building a world scale, 140,000 b/d GTL plant in Qatar that is to be operational by the end of the decade. It will be fully integrated with the development of offshore gas from North field.

A third-party study concluded that, on a life-cycle analysis basis, a Shell GTL system, compared with a conventional oil refinery, has no greater influence on global warming, but it lowers the formation of acid air and smog and reduces emissions of particulate matter.

Chevron Corp. also is developing a GTL business in several countries and has partnered with Nigerian National Petroleum Corp. to build a GTL plant to convert 320 MMcfd of gas to 34,000 b/d of liquids—primarily synthetic diesel for the European market. GTL diesel delivers higher performance and less pollution than conventional diesel, and refiners can blend the two, increasing the supply of fuel that meets stringent air-quality rules.

Chevron has invested in research and development to streamline the GTL process, making it more economical by reducing front-end costs.

A new generation of compression ignition engines is expected to expand the market for GTL, which also is well adapted for use as a liquid hydrocarbon fuel for fuel cells, said Chevron officials.

Because GTL fuel is compatible with existing diesel engines and the diesel distribution system, it is more cost-effective to introduce into markets than CNG. An independent study by the California Energy Commission concluded that GTL fuel is the most cost-effective alternative fuel for reducing emissions.

Proponents claim that GTL fuel will enable the use of ultraefficient exhaust filter devices and that it can be used in diesel-electric hybrids. Major automotive industry players are optimistic GTL’s unique properties can be used to develop more-efficient internal combustion engines.

Some see GTL technology as a platform for development of biomass-to-liquids and coal-to-liquids products with identical chemical composition.

ExxonMobil Corp. developed a new chemical method, based on the Fischer-Tropsch process, to synthesize diesel fuel from natural gas. ExxonMobil claims that better catalysts and improved oxygen-extraction technologies have reduced the capital cost of the process, and the company is vigorously marketing the process internationally.

Sasol Chevron and Qatar Petroleum completed construction of the 34,000 b/d Oryx GTL facility in Ras Laffan, Qatar, in mid-2006. The facility will use 300 MMscf of gas from North field. Construction of the other large GTL facility in Qatar, the 140,000 b/d Shell-Qatar Petroleum Pearl plant, continues despite major cost overruns. It is slated for start-up this year.

However analysts said that cost escalations have caused the cancellation or postponement of a number of proposed GTL projects until improvements occur in financial markets and product demand.